Section 02 ENGINE

Subsection 04 (COOLING SYSTEM - VEHICLE)

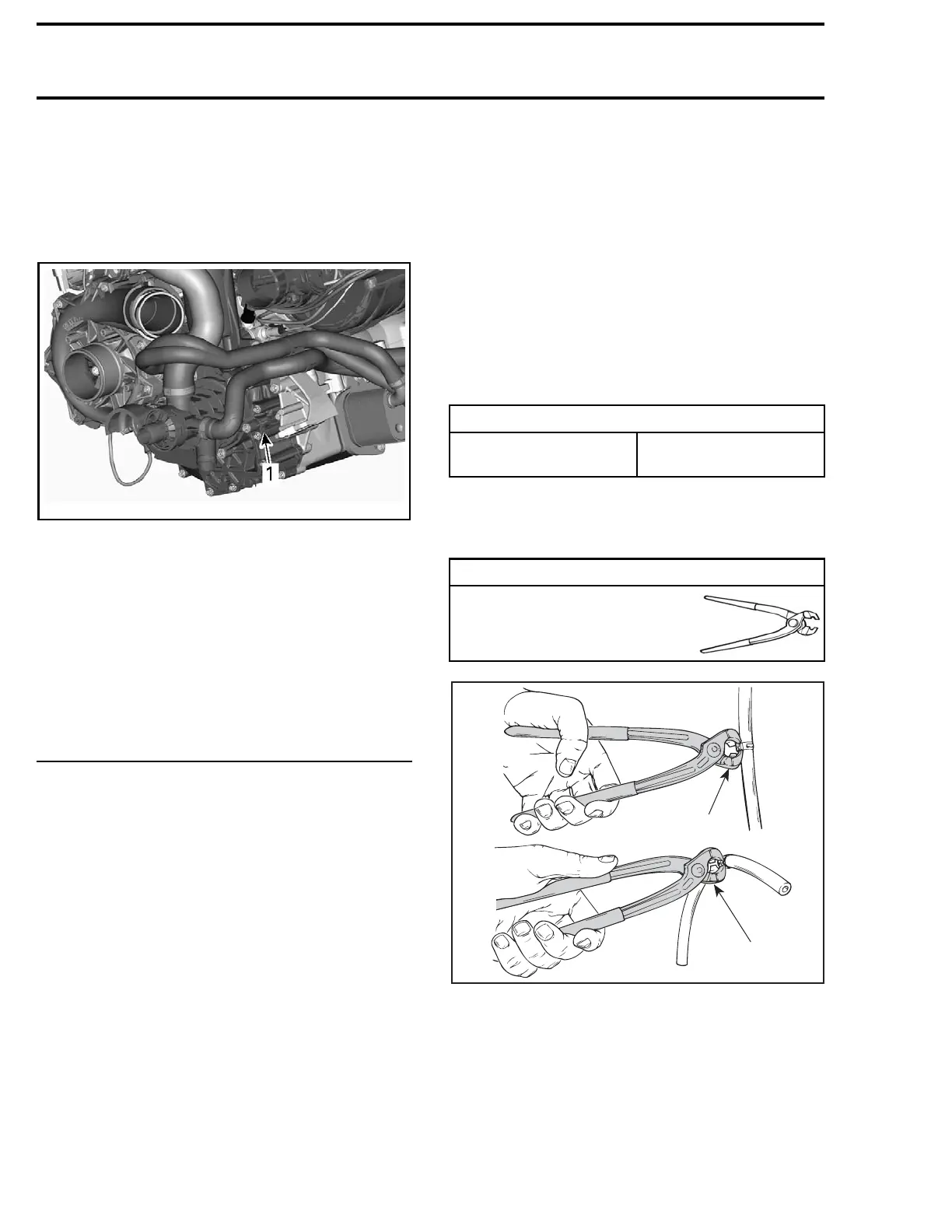

NOTE: In general leaking c oolant indicates a dam-

aged rotary seal. Leaking oil indicates a damaged

oil seal. If either seal is leaking, both seals must

be replaced at the same time. Refer to

WATER

PUMP

in

COOLING SYSTEM - ENGINE

in the ap-

propriate engine shop manual.

219100893-013-005_a

1. Leak indi

cator hole

TROUBLES

HOOTING

The following is provided to help in diagnosing the

probable s ource of troubles. It is a guideline and

it should not be assumed to list all possible prob-

lems.

Always check for fault codes. If a fault code is de-

tected, service the fault code first. Refer to

DIAG-

NOSTIC AND FAULT CODES

subsection.

ENGINE O

VERHEATING

1. Low coo

lant level.

- Refill and check for leaks (coolant leaking out

of engi

ne leak indicator hole, hoses or clam ps

missing/defective, cylinder head gaskets leaks,

ride plate leaking, etc.). Repair or replace.

2. Air in cooling system

- Refill an d bleed cooling system.

3. Thermostat defective (does not open when en-

gine g

ets hot)

- Replace thermostat housing.

4. Water pump failure

- Inspect and replace defective components.

5. Water temperature sensor defective

-Chec

k or replace. Refer to ELECTRON I C FUEL

INJECTION (EFI).

6. Ride plate or hoses damaged

-Che

ck or replace damaged components.

7. Exhaust system clogged

- Flush exhaust s ystem.

8. Internal passage blocked in cooling system

- Inspect and clean.

PROCEDURES

PRESSURE CAP

Testing the Pressure Cap

Using a pressure cap tester, check cap opening

pressure. If opening pressure is out of range, in-

stall a new pressure cap.

CAP OPENING PRESSURE

Opening range

90 kPa ± 10 k P

a

(13 PSI ± 1.5 PSI)

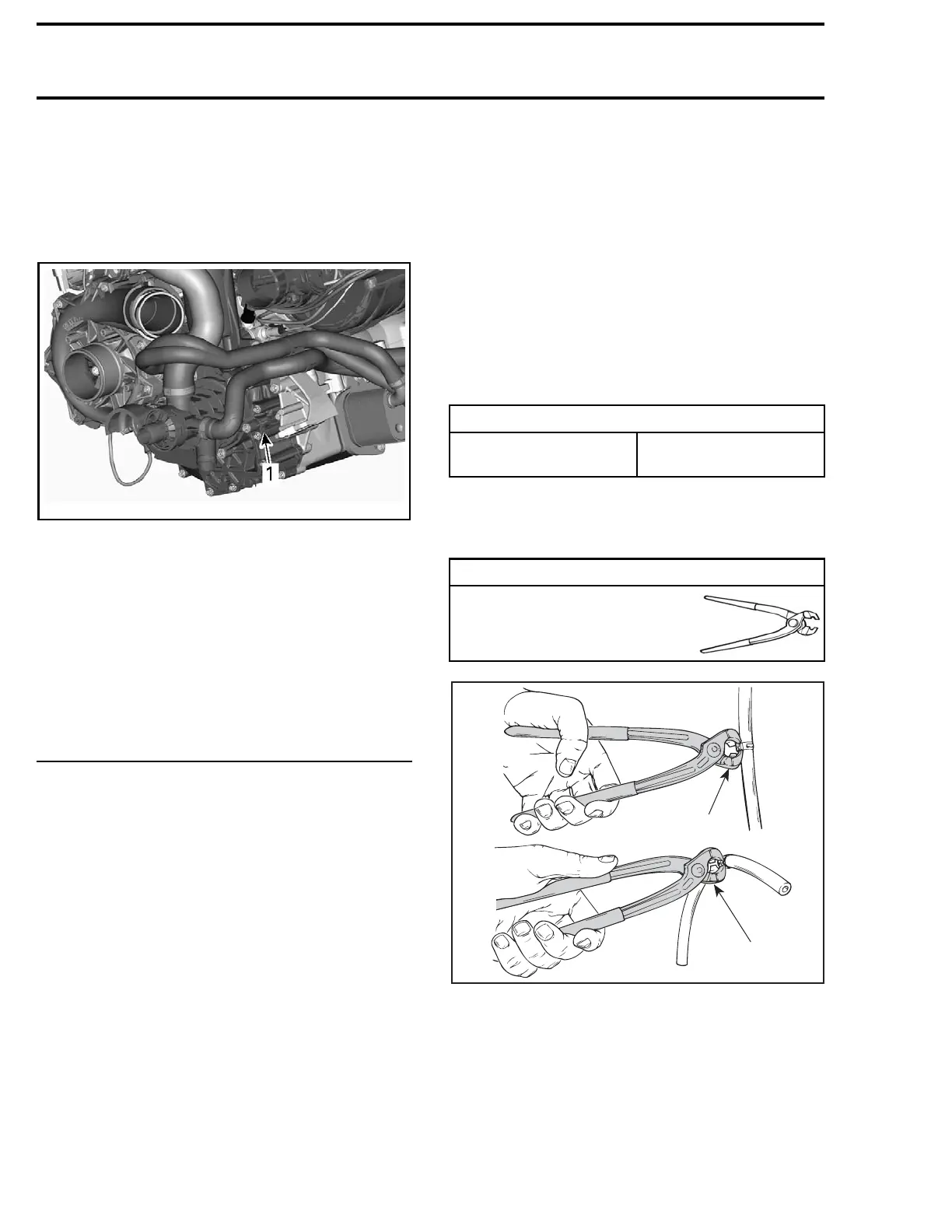

CLAMPS

Replacing t

he Oetiker Clamp

REQUIRED TOOL

OETIKER PLIER (P/N 295

000 070)

1

F01B2KA

2

1. Cutting clamp

2. Securing clamp

NOTE: Always check general condition of hoses

and clamp tightness.

54 219100963-007

Loading...

Loading...