Section 03 ELECTRONIC MANAGEMENT SYSTEMS

Subsection 01 (ENGINE MANAGEMENT SYSTEM)

GENERAL

SYSTEM DESCRIPTION

An engine management system (EMS) is used to

ensure a high power output with cleaner combus-

tion.

There are 6 mai

n systems that interact with the

engine manage

ment system:

1. Electronic fuel injection

2. D.E.S.S. System

3. Ignition Sys

tem

4. Starting System

5. T.O.P.S.

(Tip-Over Protection System)

6. iControl Sy

stem

Air management

The quantit

y of air admitted into the engine is cal-

culated by t

he throttle angle (TPS), the intake air

temperatur

e (IAT) and the manifold pressure/vac-

uum sensor

(MAP) on the intake manifold.

NOTE: the MAPTS combines the pressure and

temperature sensors into one sensor.

The operator's demands on the throttle lever are

captured by the throttle accelerator sensor (TAS)

and result in the movement of the electronic throt-

tle actuator (ETA).

Fuel management

The coolant temperature sensor (CTS) is used

to determine engine temperature. The ECM will

slightly lean out the fuel mixture to bring a cold

engine to operating temperature faster. Once the

engine is at operating temperature, this stops.

NOTE: On s

ome engines the oil temperature sen-

sor is als

o used to calculate engine temperature.

In response to changes in air management, the

ECM will adjust the quantity of fuel injected to op-

timize combustion.

The ECM will vary injection duration and timing to

minimize emissions and maximize power.

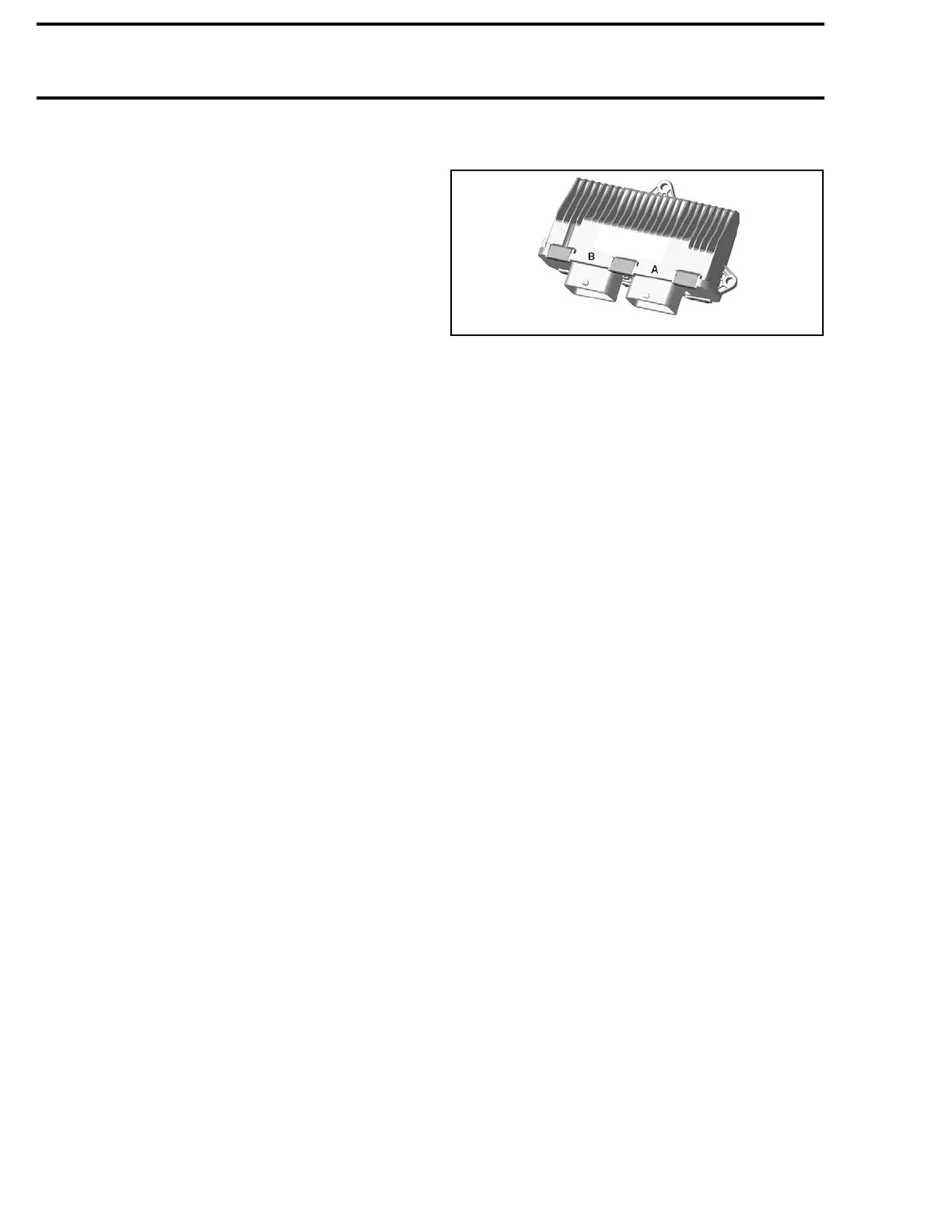

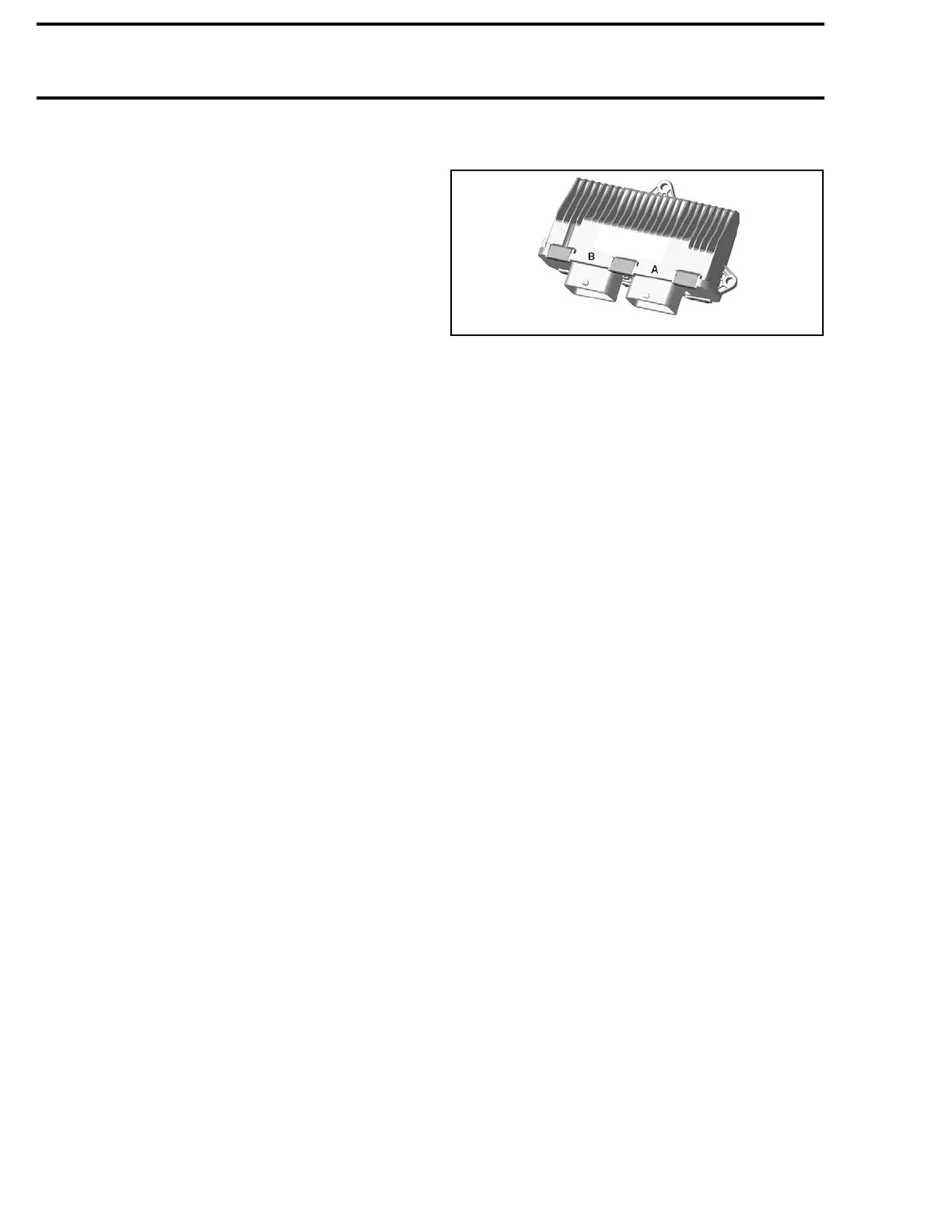

Engine Control Module (ECM)

smr2009-027-005

ECM

The ECM is the main component of the engine

management system. It controls the electrical

system and the engine management functions by

processing the information obtained from various

switches, controls and sensors that it compares

to predetermined parameters stored in the ECM.

It also inte

racts with the other electronic systems

through th

e CAN bus (information center and

iControl S

ystem) for various functions that affect

engine man

agement.

It features a permanent memory that will store

fault codes, customer information and other

engine information, even when the battery is

removed from the vehicle.

The ECM controls the following engine manage-

ment functions:

Engine RP

M Limiter

The ECM limits maximum engine speed. It moni-

tors engine RPM through the CPS and varies fuel

injection, ignition and throttle plate opening as

necessary.

Engine Speed Control

The ECM co

ntrols the engine idle RPM. In addi-

tion, it c

an vary the engine speed by command-

ing the e

lectronic throttle actuator (ETA) to open or

close ba

sed on throttle position and various other

inputs.

The ETA also allows for other functions of

the iCon

trol system.

Monitoring System

The ECM monitors:

– The electrical and electronic components of the

engine system

– The iCo

ntrol system

– The information center (gauge)

– Some components of the electrical system

– Signal

s from other electronic modules

For more information, refer to

DIAGNOSTIC AND

FAULT CODES.

64 219100963-009

Loading...

Loading...