Section 06 STEERING AND PROPULSION

Subsection 02 (iBR, REVERSE AND VTS)

GENERAL

During assembly/installation, use torque values

and service products as indicated in the exploded

view.

Clean threads

before applying a threadlocker. Re-

fer to

SELF-LO

CKING FA S TENERS

and

LOCTITE

APPLICATION

a

t the beginning of this manual for

complete pro

cedure.

WARNING

Torque wrench tightening specifications

must be strictly adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, cotter pins,

etc.) must be replaced with new ones.

Hoses, cables or locking ties removed during a

procedure must be reinstalled as per factory stan-

dards.

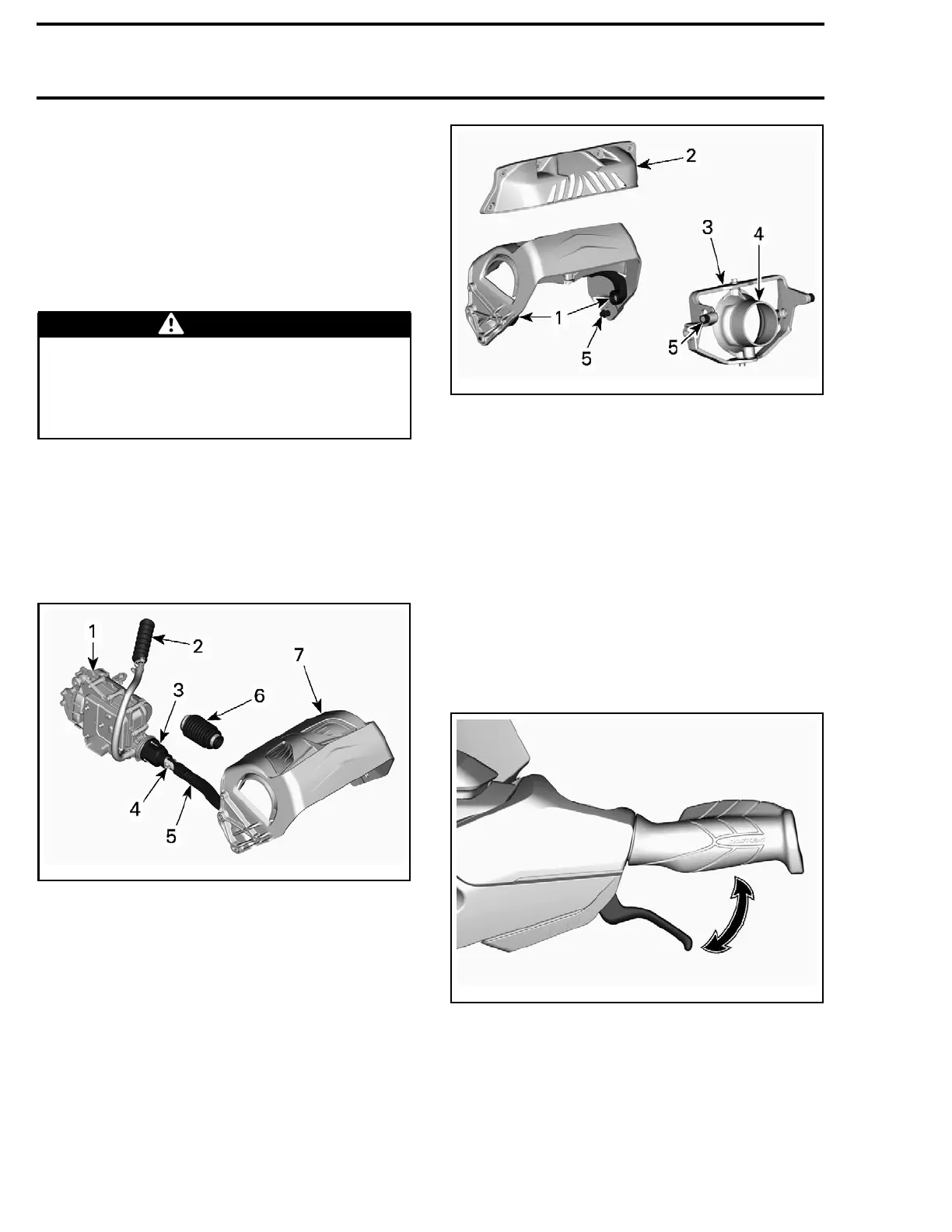

SYSTEM DESCRIPTION (iBR)

iBR System Components

219100893-029-001_a

TYPICAL

1. Actuat

or

2. Air chamber

3. iBR nut

4. Actua

tor shaft

5. Connecting arm

6. Connecting arm bellows

7. iBR Re

verse Gate

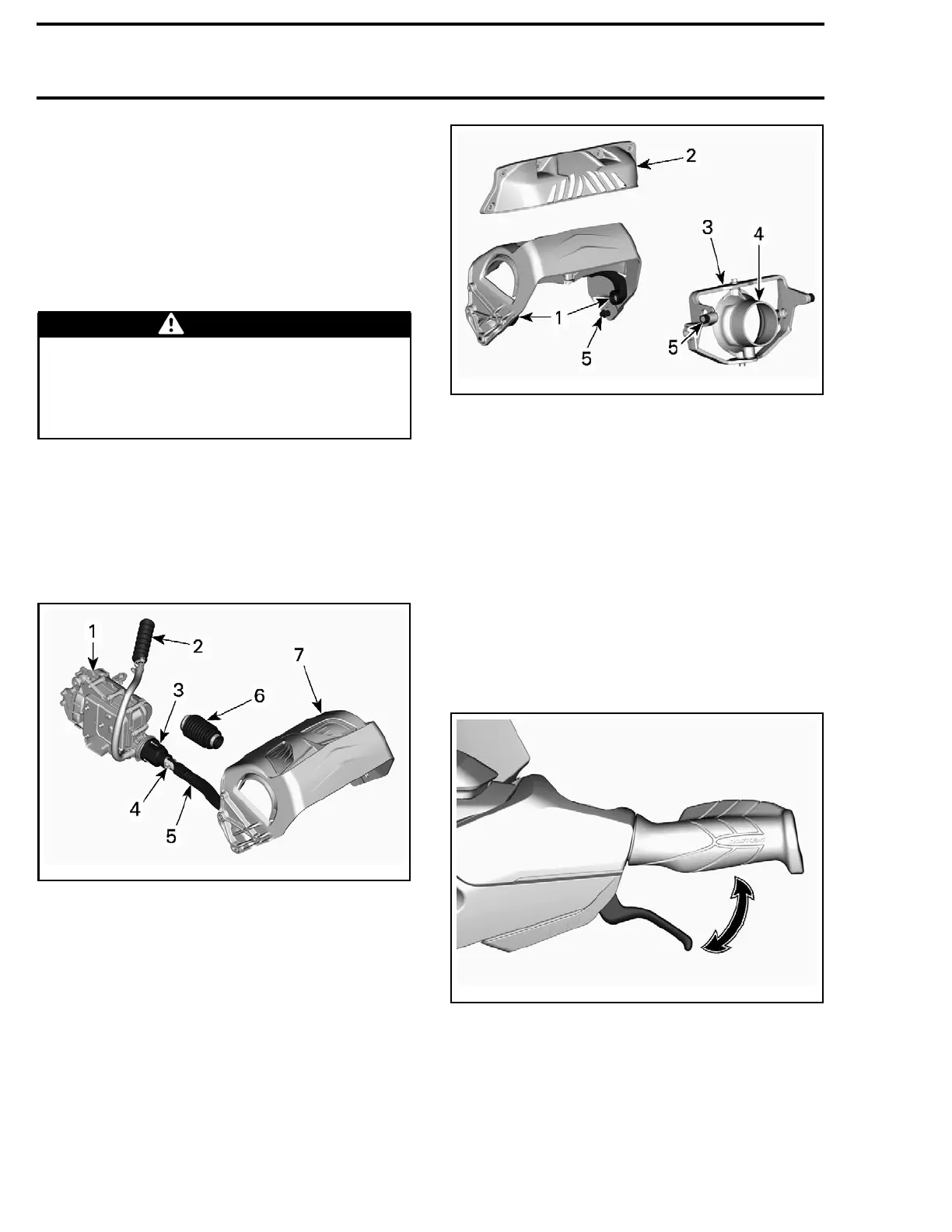

219100893-029-002_a

1. Support plates

2. Protective guard

3. VTS trim

4. Nozzle

5. Friction sleeves

The iBR (intelligent Brake and Reverse) is an elec-

tronically controlled braking and reverse system.

The iBR module controls the position of the iBR

gate to provide forward thrust, reverse thrust,

braking thrust, and neutral.

The operator commands the position of the iBR

gate using either the throttle lever for forward

thrust, or the iBR lever for neutral, reverse, and

for the braking function.

The iBR lever is located on the LH side of the han-

dlebar.

219100893-029-005_a

When t

he iBR lever is pulled in, it operates the

brake

and reverse lever sensor (BRLS). It is a dou-

ble ou

tput hall effect sensor. The redundancy is

used

for security purposes.

The BRLS sends the signals to the iBR module.

The iBR module controls an electric motor that in

turn raises or lowers the iBR gate through a me-

chanical drive unit.

168 219100963-018

Loading...

Loading...