Section 04 FUEL SYSTEM

Subsection 02 (FUEL TANK AND FUEL PUMP)

When the ECM receives a signal to shut down

the engine (START/STOP switch, engine cut-off

switch, or T.O.P.S. switch) it removes the fuel

pump g round signal.

Fuel Level Indication

An electric float type fuel level sensor is mounted

on the side of the fuel pump reservoir. As the float

moves with changing fuel levels, it varies a resis-

tance that changes the voltage signal coming from

the information center (multifunction gauge). This

signal is representative o f the fuel level.

The information center interprets the fuel level

voltage signal that comes back from the fuel level

sensor. It then displays the proper fuel level in

the information center and a low fuel warning

message when required.

The information center will also trigger the beeper

which produces the appropriate beep signal to

warn the driver of a low fuel condition.

The fuel level sensor resistance is at its lowest

value when the fuel tank is full, and at its highest

value when the tank is empty.

Refer to the

FUEL LEVEL SENSOR

in this subsec-

tion for fuel level sensor testing procedures.

Fuel Tank Venting

The entire vent system is incorporated within the

fuel tank cap.

WARNING

If the cap requires replacement, it must be re-

placed with an approved vented cap of the

same type supplied by BRP. Use of any other

cap, or use of a non-vented cap will not al-

low proper venting of the fuel tank. The re-

sult may be engine fuel starvation, fuel tank

overpressure, or fuel leaks which could lead

toafireoranexplosion.

INSPECTION

TESTING FUEL TANK FOR LEAKS

1. Visually inspect condition of hoses and clamps.

2. Remove

/open fuel tank cap.

3. Fill up fuel tank.

4. Install test cap on filler neck.

5. Use th

e following tool to pressurize fuel tank.

REQUIRED TOOL

VACUUM /PRESSURE PUMP

(P/N 529 021 800)

FUEL TANK TEST CAP

(P/N 529 036 242)

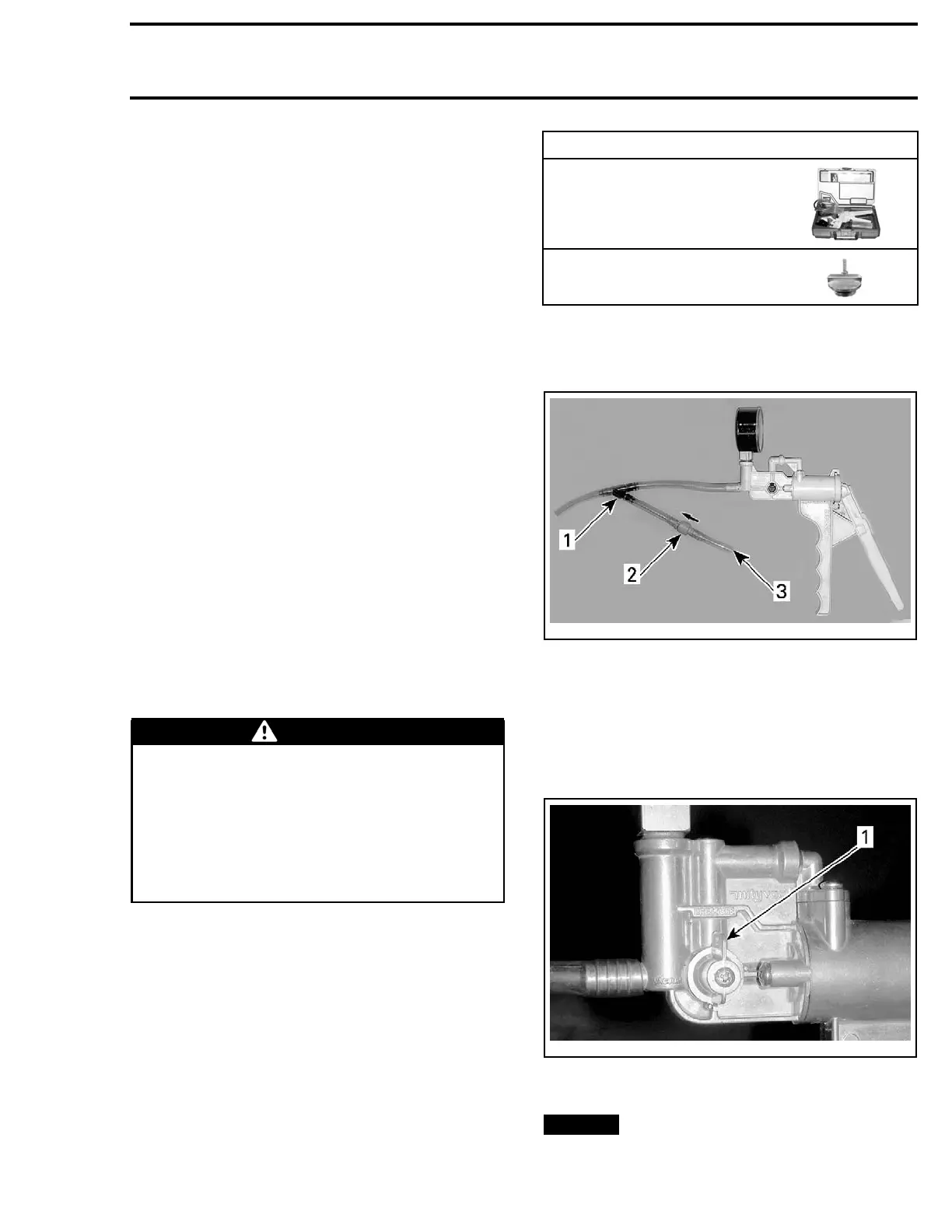

NOTE: AY-fit

ting and a check valve can be in-

stalled to us

e compressed air for quick pressure

build-up whe

n the fuel tank is not full.

mmr2009-121-004_a

1. Y-fitting (P/N 293 710 059)

2. Check valve (P/N 275 500 505)

3. Apply compressed air here

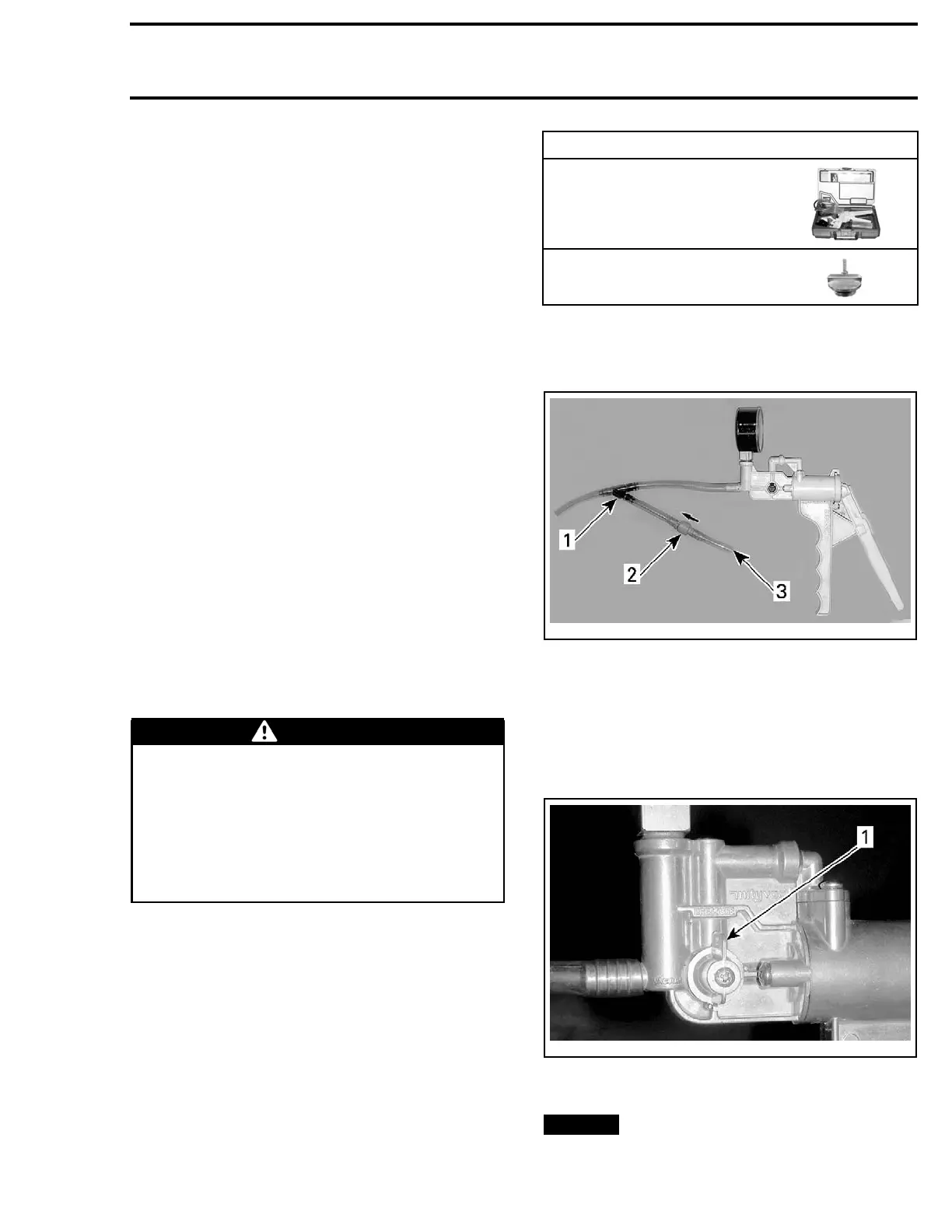

6. Install the fuel tank test cap.

7. Connect the vacuum/pressure pump to the nip-

ple of fuel tank test cap.

8. Set vacuum/pressure pump to PRESSURE.

smr2

009-031-012_a

1. Pressure selected

9. Pressurize fuel tank to specification.

NOTICE

Do n

ot exceed the specification

whe

n pressurizing the fuel tank.

219100893-021 91

Loading...

Loading...