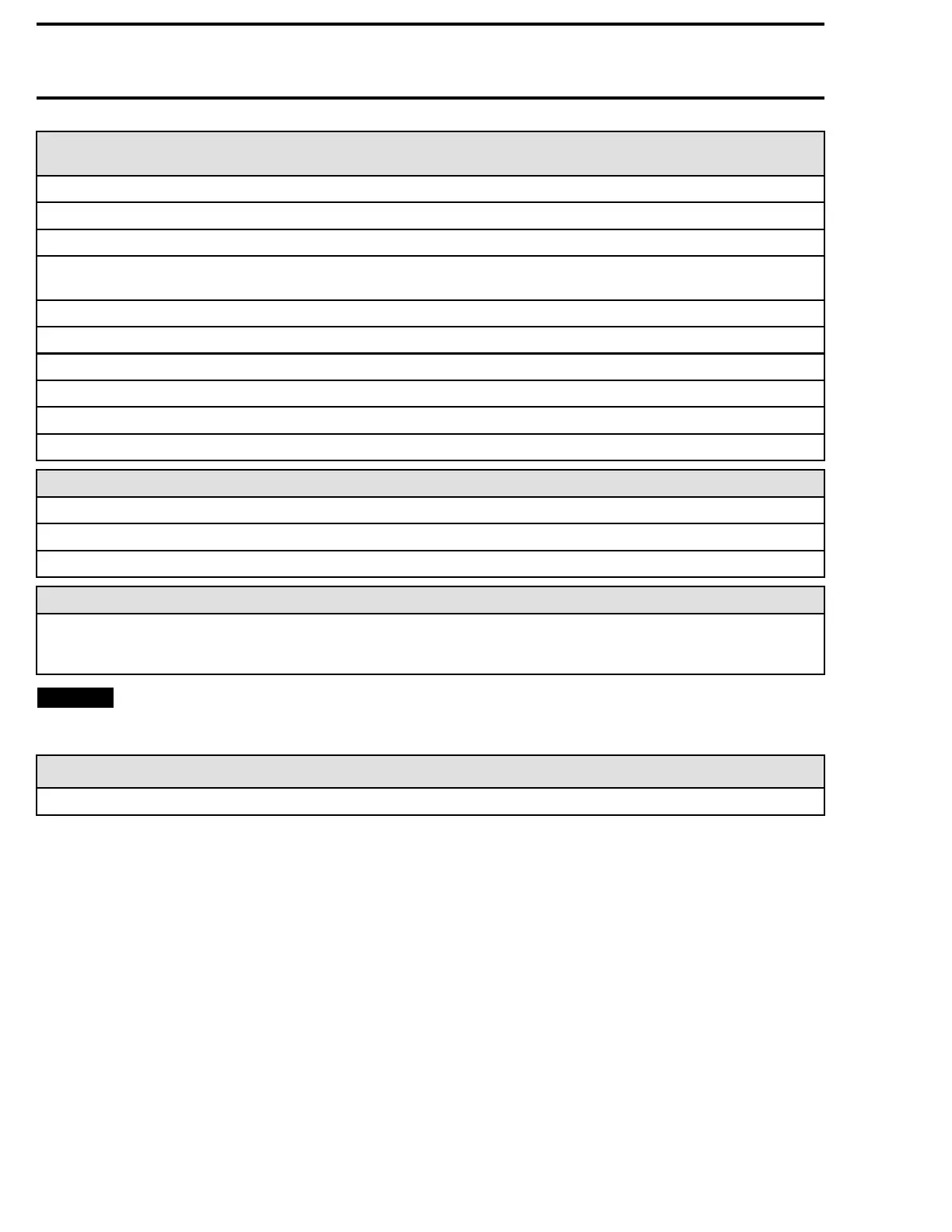

Section 01 MAINTENANCE

Subsection 01 (MAINTENANCE SCHEDULE)

EVERY YEAR AT PR

ESEASON OR 100 HOURS OF OPERATION

(WHICHEVER COMES FIRST)

Visually insp

ect connection between throttle b ody and intake manifold

Inspect the air intake for damage on hoses a nd clamps.

Inspect electrical connectio ns and fastening (ignition system, starting system, fuel injectors, fuse box etc.)

Visually ins

pect area around carbon ring and drive shaft rubber bellow for the following signs of failure: black

carbon dust and water sprays (more frequently when using PWC in dirty water)

Visually in

spect impeller and bellow

Measure th e clearance between the impelle r and the w e ar ring

Remove impeller cover and inspect for signs of water intrusion

Visually i

nspect reverse gate bushing for excessive play

Inspect fuel s ystem (cap, filler neck, fuel tank, straps, fuel lines and connections)

Visually inspect coolant level in transducer support, top-off if necessary (if equipped)

EVERY 200 HOURS OF OPERATION

Replace spark plugs

Validate condition of bearing by manually spinning impeller checking for radial shaft play or noise

Verify and lubricate splines of the drive shaft and impeller

MAINTENANCE FREE

230 and 300 engines: The supercharger is maintenance free*.

*Inspect supercharger every 200 hours (irrespective of the number of years) when vehicle is used in intense

conditions such as off-shore riding, continuous operation at wide open throttle, etc.

NOTICE

Do not attempt to replace components of the supercharger assembly as the unit is fac-

tory- balanced to precise specifications. Failure to follow this recommendation may lead to super-

charger and / or engine damage.

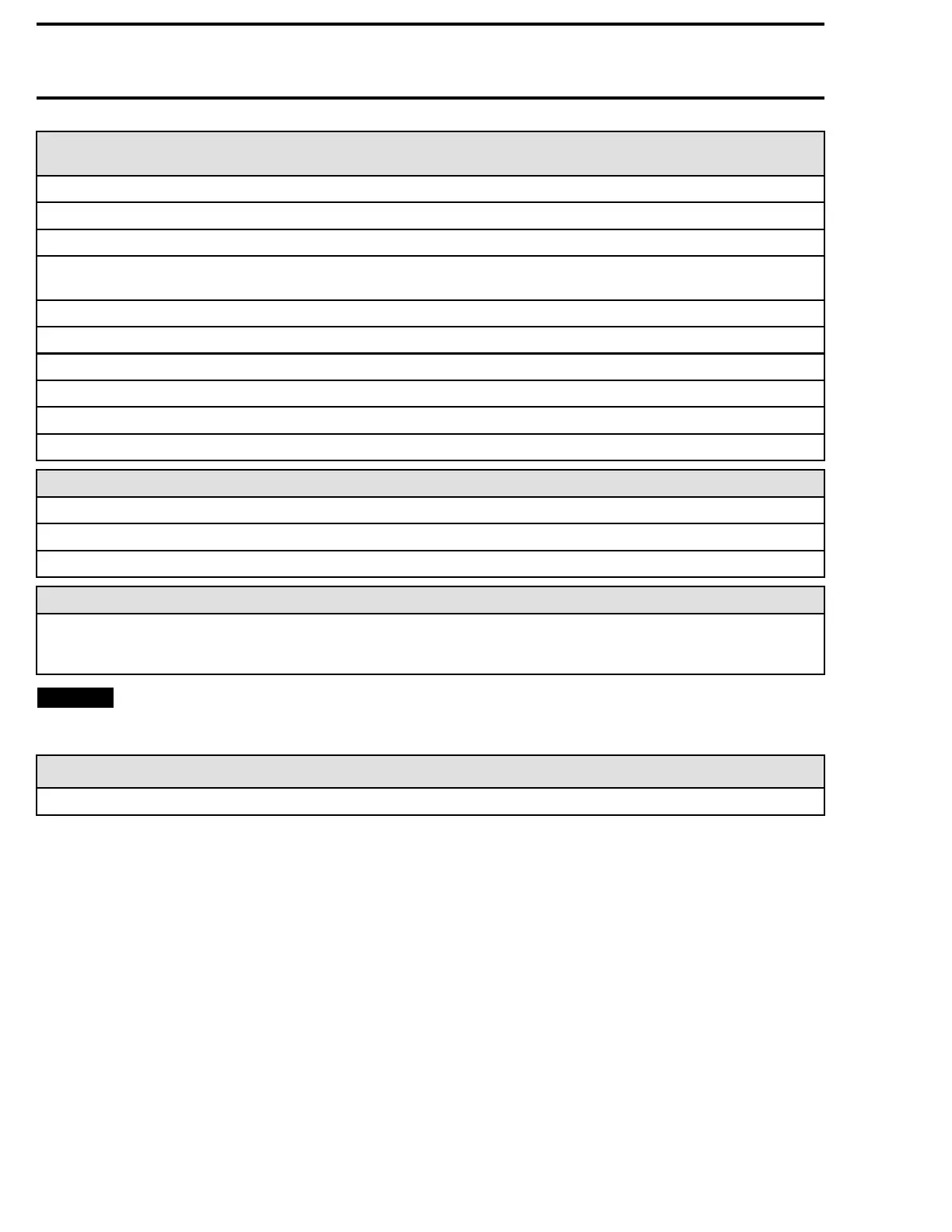

EVERY5YEARSOR300HOURSOFOPERATION

(WHICHEVER COMES FIRST)

Replace the coolant

6 219100963-002

Loading...

Loading...