Section 01 MAINTENANCE

Subsection 04 (SPECIAL PROCEDURES)

2. Remove the air intake silencer and check for

water in the supercharger inlet hose. Remove

hose to empty it.

3. Remove the water from blow-by valve hose.

4. If water is suspected in the intake manifold,

remove the intake manifold and drain it. Then

siphon the water out from the intake valve

ports. Refer to

INTAKE MANIFOLD

subsec-

tion.

Replacing the Engine Oil and the Filter

If the engine oil is contaminated with water (oil will

be milky), change the engine oil and filter as per

following procedure.

1. Using the suction pump, siphon the contami-

nated oil from the engine reservoir through the

dipstick hole.

REQUIRED TOOL

SUCTION PUMP

(P/N 529 035 880)

NOTICE

Never cra

nk or start engine when

siphon tu

be is in dipstick hole. Never start

engine wh

en there is no oil in engine.

2. Remove the suction pump tube from the dip-

stick hole.

3. Fully de

press throttle lever and HOLD it for

crankin

g.

4. Crank the engine for 5 seconds.

5. Remove the oil filter cap and the oil filter. Refer

to appropriate

LUBRICATION SYSTEM

subsec-

tion.

6. Again,

siphon the contaminated oil from the oil

filte

r reservoir.

7. Remove valve cover. Refer to appropriate

CYLINDER HEAD

subsection.

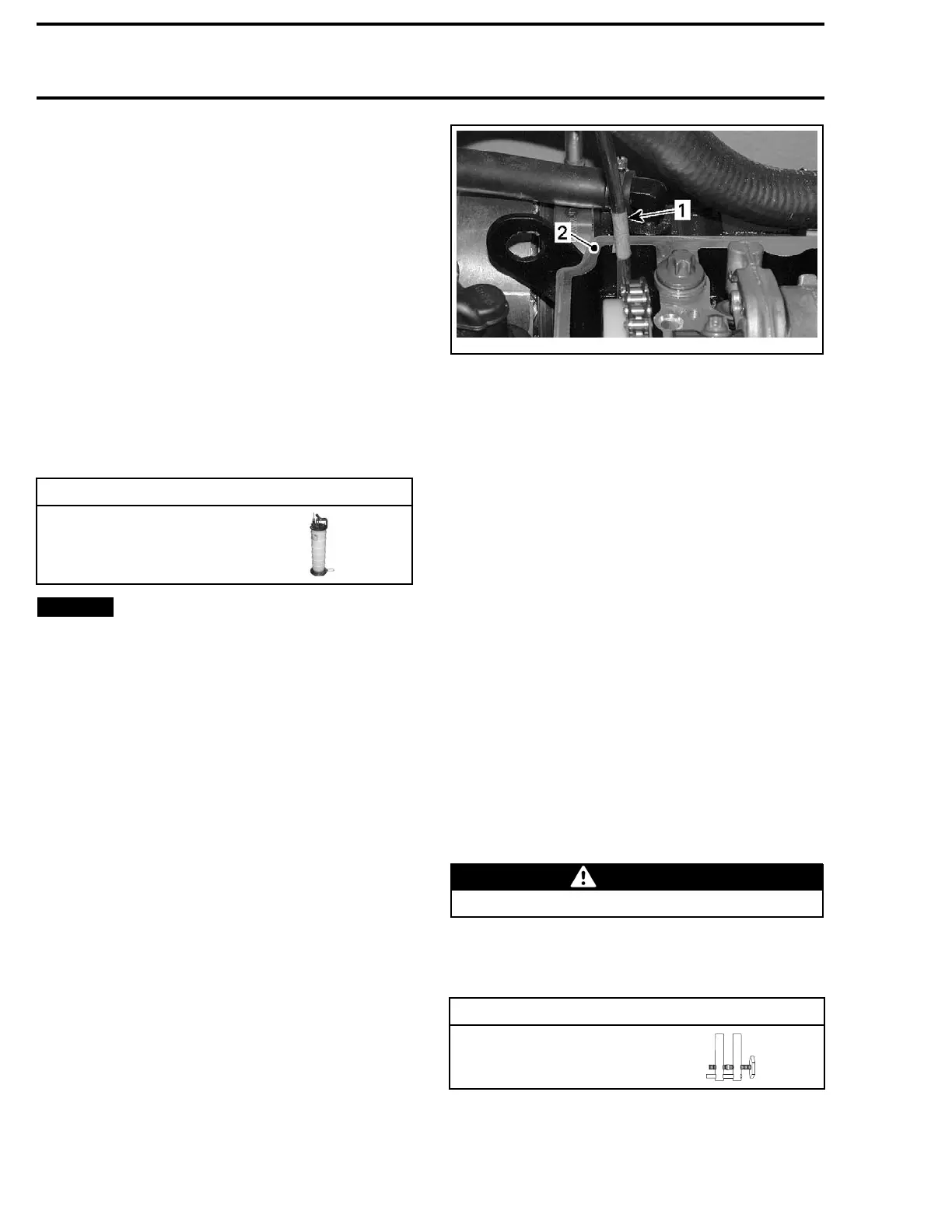

8. Wrap a piece of tape around the suction pump

tube 400 mm (16 in) from the end of the tube.

9. Inse

rt the tube in the PTO area until the tape is

even

with the cylinder-block edge.

10. S iphon contaminated oil out.

smr2006-006-003_a

TYPICAL

1. Suction pump tube with tape

2. Edge of cylinder-block

11. Remove the suction pump tube.

12. Reinstall valve cover.

13. Install a NEW oil filter and reinstall the oil filter

cap.

14. Replenish the engine with appropriate amount

of the recommended engine oil. Refer to ap-

propriate

LUBRICATION SYSTEM

subsection.

15. Proceed with the

BOIL OUT PROCEDURE

that follows.

NOTE: The boil out procedure is intended to evap-

orate a small quantity of water contained in the oil

system.

Boil Out Procedure in a Test Tank or Tied to a

Trailer with Watercraft in Water

1. Connect the vehicle to the BRP diagnostic soft-

ware (BUDS2) to monitor the c oolant temper-

ature. Coolant temperature must exceed 80°C

(176°F) in order for the water to boil out. Once

the boiling point is attained, the water will evap-

orate quickly.

2. Run the engine for 5 minutes at 3500 RPM.

WARNING

Be sure to safely secure the watercraft.

3. With the engine still running at 3500 RPM, in-

stall a large hose pincher on the coolant line go-

ing to the oil cooler.

REQUIRED TOOL

LARG

EHOSEPINCHER

(P/N 529 032 500)

14 219100963-005

Loading...

Loading...