Sysmex XP-300 9-3

Quality Control

Revised October 2012

Procedure

Preparing control blood

(1) Remove a vial of control material from the refrigerator and

equilibrate to room temperature (18-30ºC) for 15 minutes before

use.

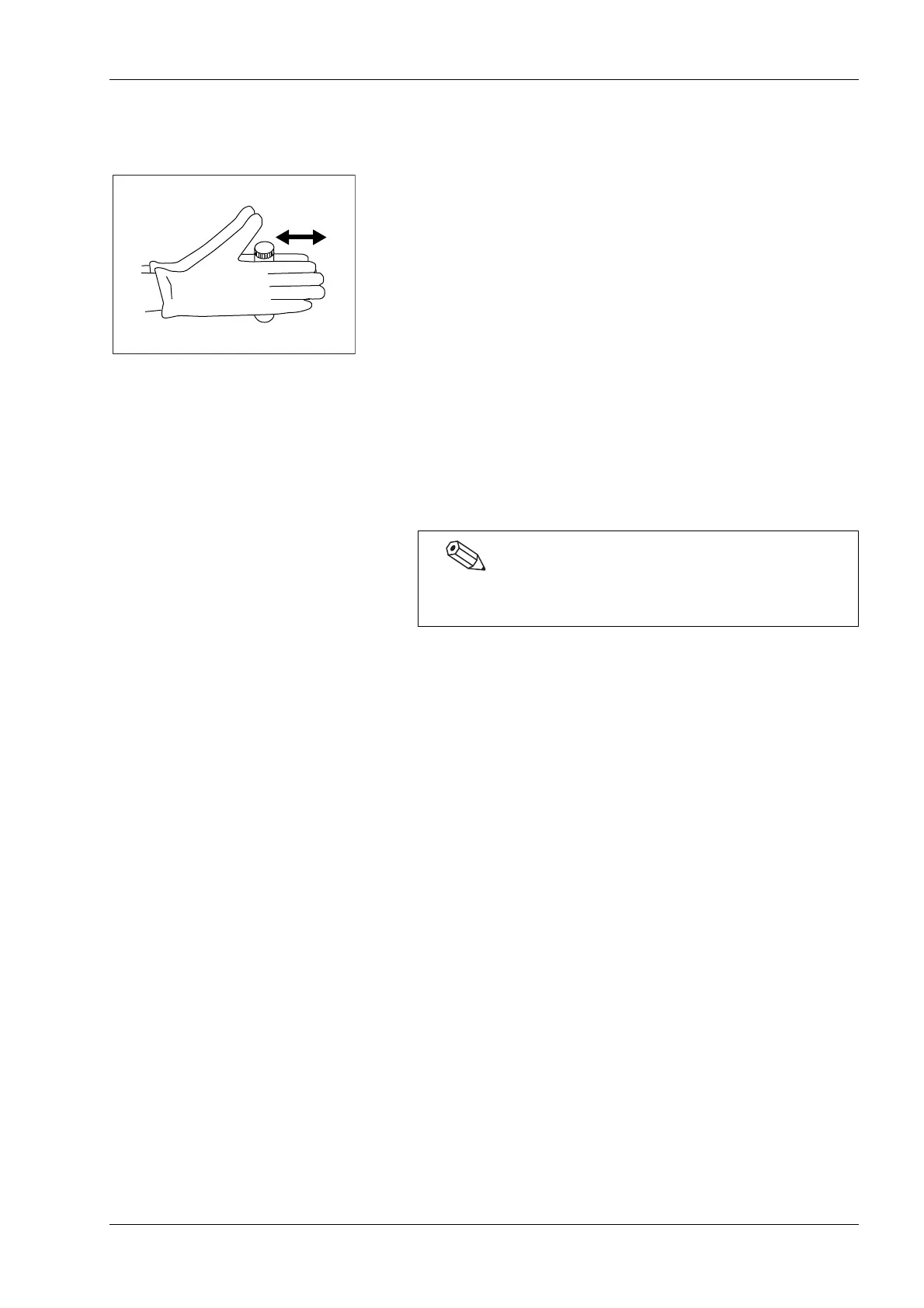

(2) Place the vial between the palms and roll it back and forth 10

times (see illustration).

(3) Turn the vial upside down and roll 10 more times.

(4) Repeat steps (2) and (3) 8 times or for a total of 2 minutes.

Examine the bottom of the vial and assure thoroughly mixing

by confirming that there is no pellet of cells adhering to the

bottom of the vial before performing the analysis. If there still is

pellet of cells, repeat step (3).

(5) Analyze the control blood sample in the same manner as patient

whole blood, according to procedures listed in the instrument’s

Instructions for Use. Wipe threads of cap and vial with clean

lint-free tissue before replacing cap. Recap vial tightly.

(6) Store at 2-8ºC in an upright position.

Manual procedures

Reference method can be applied to EIGHTCHECK-3WP-N,

EIGHTCHECK-3WP-L and EIGHTCHECK-3WP-H. Refer to a

manual for clinical laboratory procedures.

Methodology

Principle of the method

EIGHTCHECK-3WP-N, EIGHTCHECK-3WP-L and

EIGHTCHECK-3WP-H are to be used as hematology control bloods

for the quality control of any Sysmex fully automated and semi-

automated hematology analyzers. EIGHTCHECK-3WP-N is for the

normal level, EIGHTCHECK-3WP-L is for the low abnormal level

and EIGHTCHECK-3WP-H is for the high abnormal level.

The WBC histogram of EIGHTCHECK-3WP-N, EIGHTCHECK-

3WP-L and EIGHTCHECK-3WP-H indicate 3 part distributions

when the instrument’s particle distribution analysis is used.

The use of stabilized cell preparation for controlling hematology

instrumentation is an established procedure. When handled like a

patient sample measured in QC mode and assayed on a properly

calibrated (HGB, HCT) and functioning instrument,

EIGHTCHECK-3WP-N, EIGHTCHECK-3WP-L and

EIGHTCHECK-3WP-H will provide values within the expected

range indicated on the assay sheet.

Always check with current control materials insert

instructions.

Loading...

Loading...