ProcedureforTractionCircuitReliefPressureTest

1.Makesurehydraulicoilisatnormaloperatingtemperature(54to66ºC(130

to150ºF))byoperatingthemachineforapproximatelyten(10)minutes.

Makesurethehydraulictankisfull.

CAUTION

PerformTractionCircuitReliefPressureTestinanopenarea,away

frompeopleandobstructions.

2.Drivemachinetoanopenarea,fullyraisecuttingdecks,engageparking

brakeandturntheengineoff.

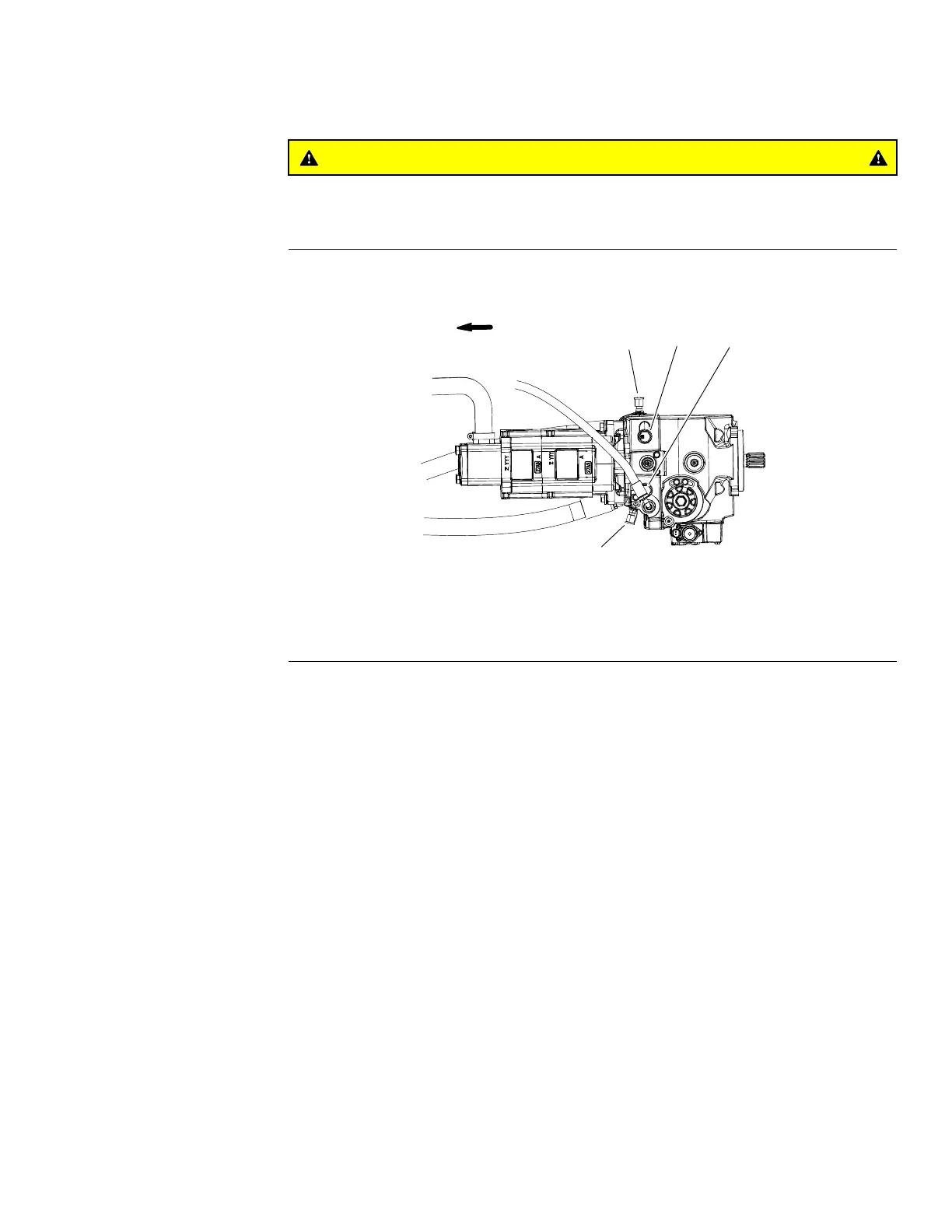

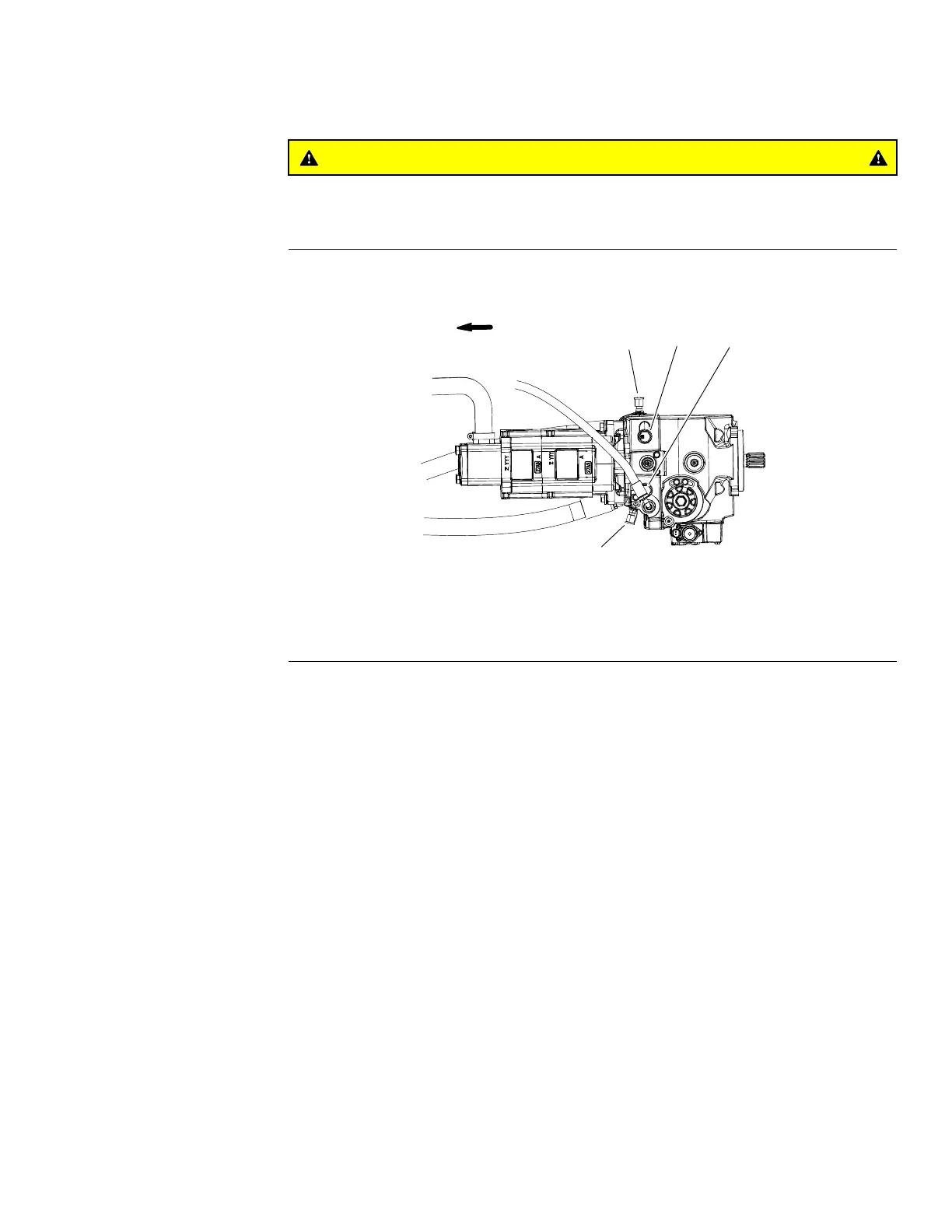

g287737

Figure52

1.Forwardtestport(MA)3.Forwardreliefvalve

2.Reversetestport(MB)

4.Reversereliefvalve

3.Connecta700Bar(10,000PSI)pressuregaugewithhydraulichoseattached

totractioncircuittestportforfunctiontobechecked(Figure52).Route

gaugehosetoallowoperatortoviewthegauge.

4.Afterinstallingpressuregauge,startengineandrunatlowidlespeed.Check

forhydraulicleakageattesterconnectionsandcorrectbeforeproceeding

withtest.

5.Sitonseatandoperatetheengineathighidlespeed(2530RPM).Makesure

thatmachineisinthehighrangetractionspeed(transport).

6.Drivemachinesofronttiresarewedgedagainstanimmovableobject(e.g.a

curb)topreventwheelrotationinthedirectiontobetested.Analternative

wouldbetopositionthemachineonaninclinedsurfacetoallowahigh

tractionloadinthedirectiontobetested.

7.Slowlydepressthetractionpedalintheappropriatedirection(forwardor

reverse).Whilepushingtractionpedal,lookatpressurereadingongauge.

Asthetractionreliefvalvelifts,thegaugeneedlewillstopmomentarily.

GAUGEREADINGTOBE:

402to411bar(5825to5965PSI)inforward(MAport)

397to407bar(5760to5910PSI)inreverse(MBport)

8.Releasetractionpedalandstopengine.Recordtestresults.

Groundsmaster

®

5900&5910

Page5–43

HydraulicSystem:Testing

16227SLRevB

Loading...

Loading...