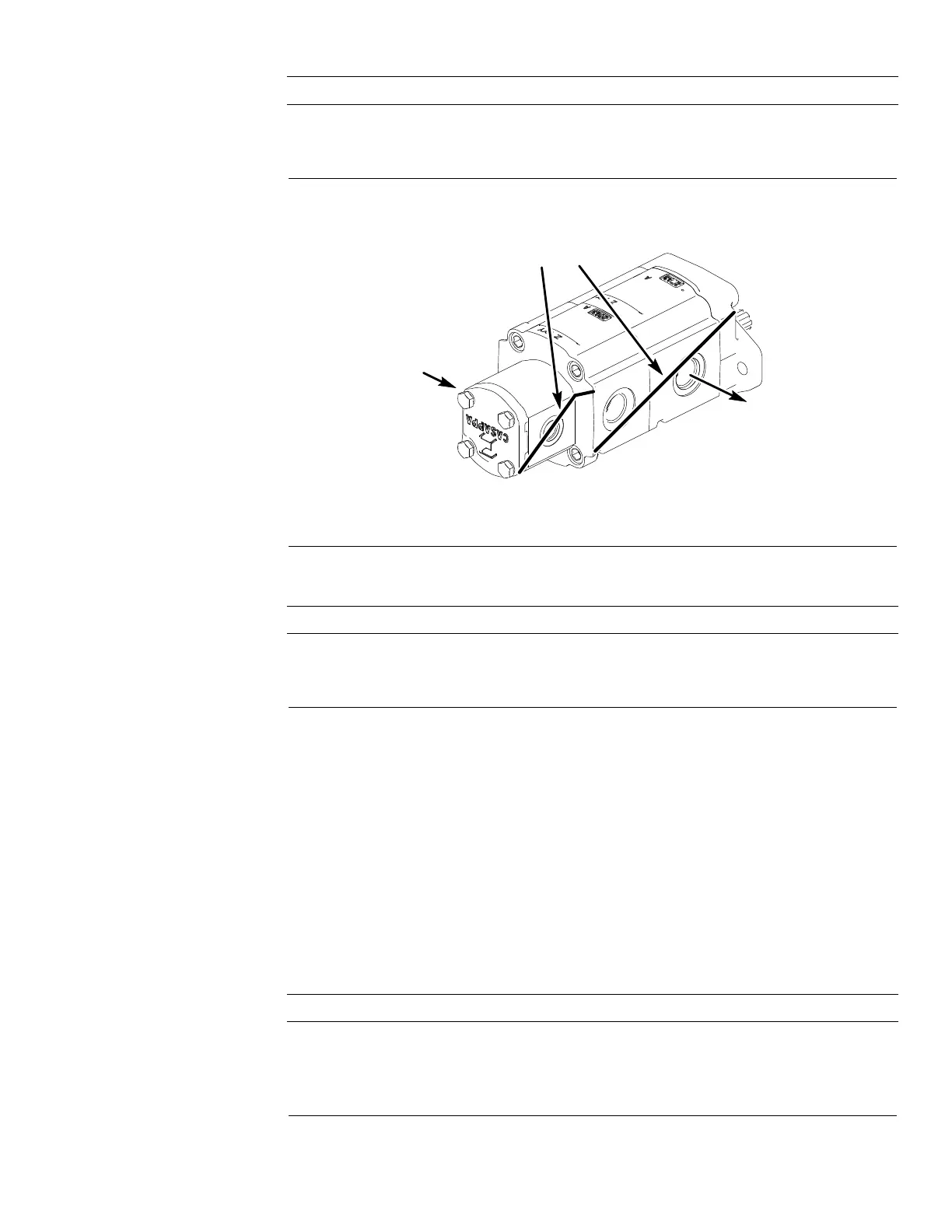

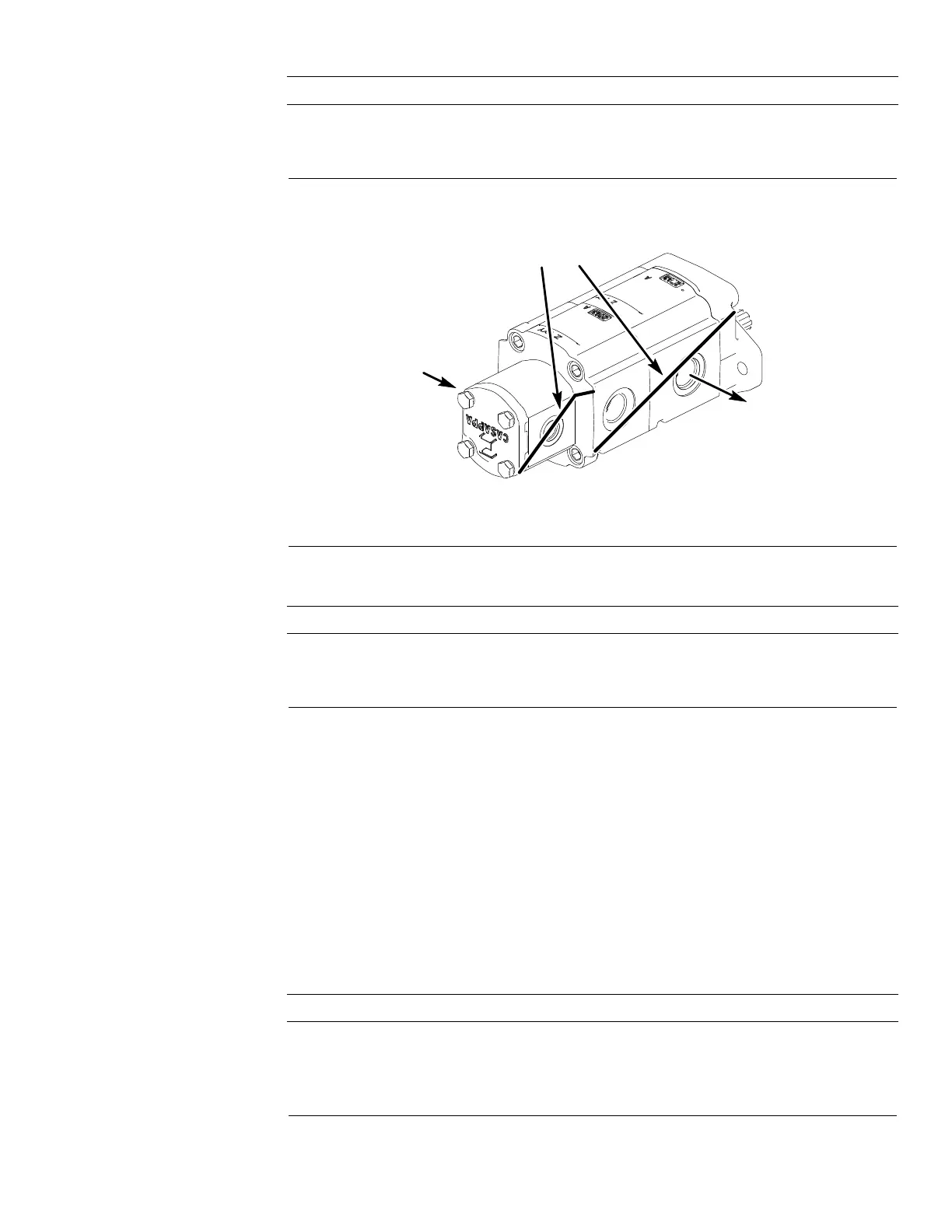

GearPumpDisassembly(Figure82)(continued)

IMPORTANT

Keepbodies,gears,angesandthrustplatesforeachpumpsection

together;donotmixpartsbetweenpumpsections.

1.Plugpumpportsandthoroughlycleanexteriorofpumpwithcleaningsolvent.

Makesureworkareaisclean.

DIAGONAL LINE

P3

P2

P1

OIL

IN

OIL

OUT

g287891

Figure83

2.Useamarkertomakediagonallinesacrossthegearpumpsectionsfor

assemblypurposes(Figure83).

IMPORTANT

Usecautionwhenclampinggearpumpinavisetoavoiddistorting

anypumpcomponents.

3.Securethefrontcoverofthepumpinavisewiththedriveshaftpointingdown.

4.SupportpumpsectionP3andgentlytapthepumpbodywithasoftface

hammertoloosenthepumpsection.RemovepumpsectionP3fromthe

remainderofthepumpasanassembly.Becarefultonotdroppartsor

disengagegearmesh.

5.Loosenthefour(4)capscrewsthatsecurethelargerpumpsections(P1

andP2)tothefrontcover.

6.Removepumpfromviseandremovefasteners.

7.Supportthepumpassemblyandgentlytapthepumpbodieswithasoft

facehammertoloosenthepumpsections.Becarefultonotdroppartsor

disengagegearmesh.

IMPORTANT

Marktherelativepositionsofthegearteethandthethrustplatesso

theycanbereassembledinthesameposition.Donottouchthegear

surfacesasresidueonhandsmaybecorrosivetogearnish.

Groundsmaster

®

5900&5910

Page5–89

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...