Piston(Traction)PumpRemoval(Figure87)(continued)

3.Removedrainplugfromthehydraulicreservoiranddrainreservoirinto

asuitablecontainer.

4.Topreventcontaminationofhydraulicsystemduringremoval,thoroughly

cleanexteriorofpumpassembly.

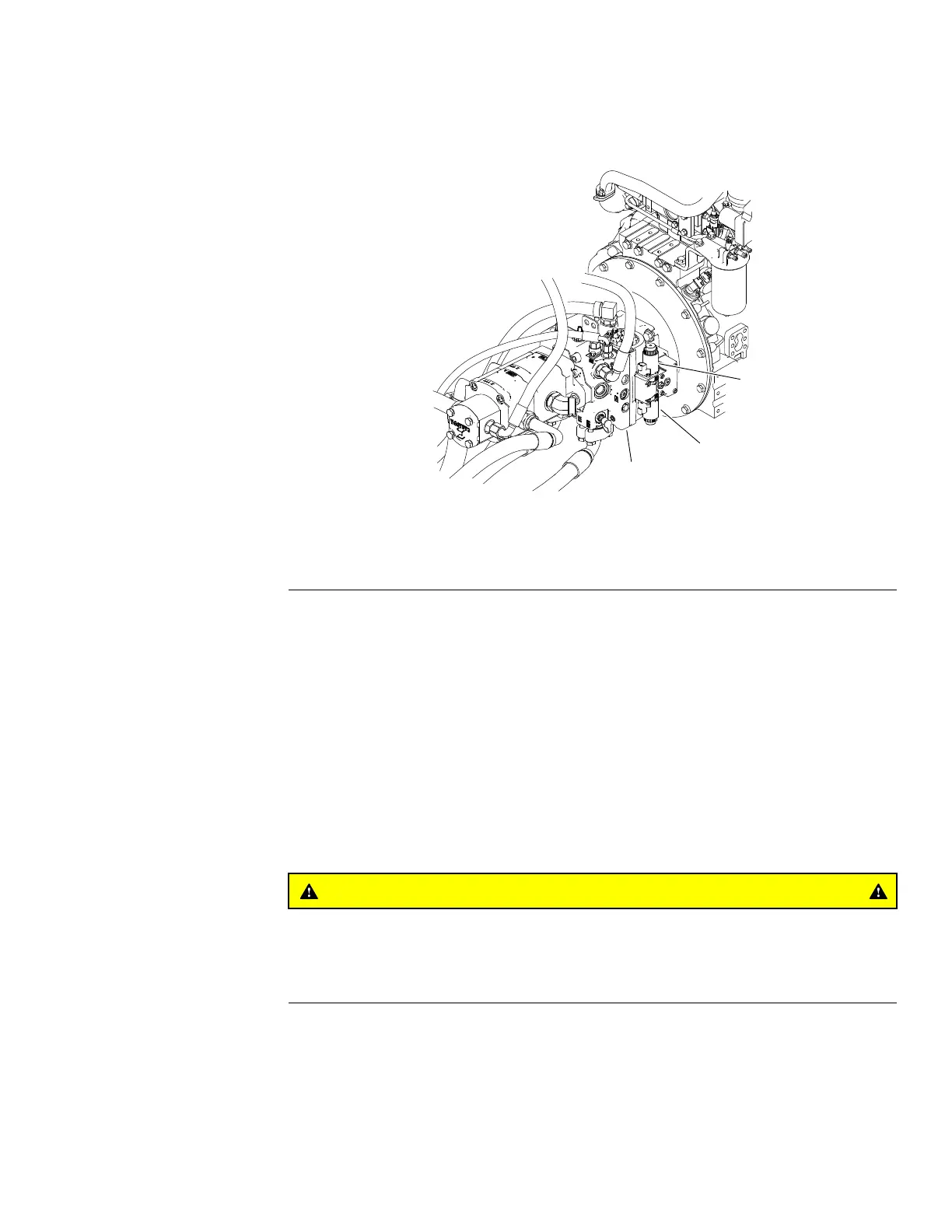

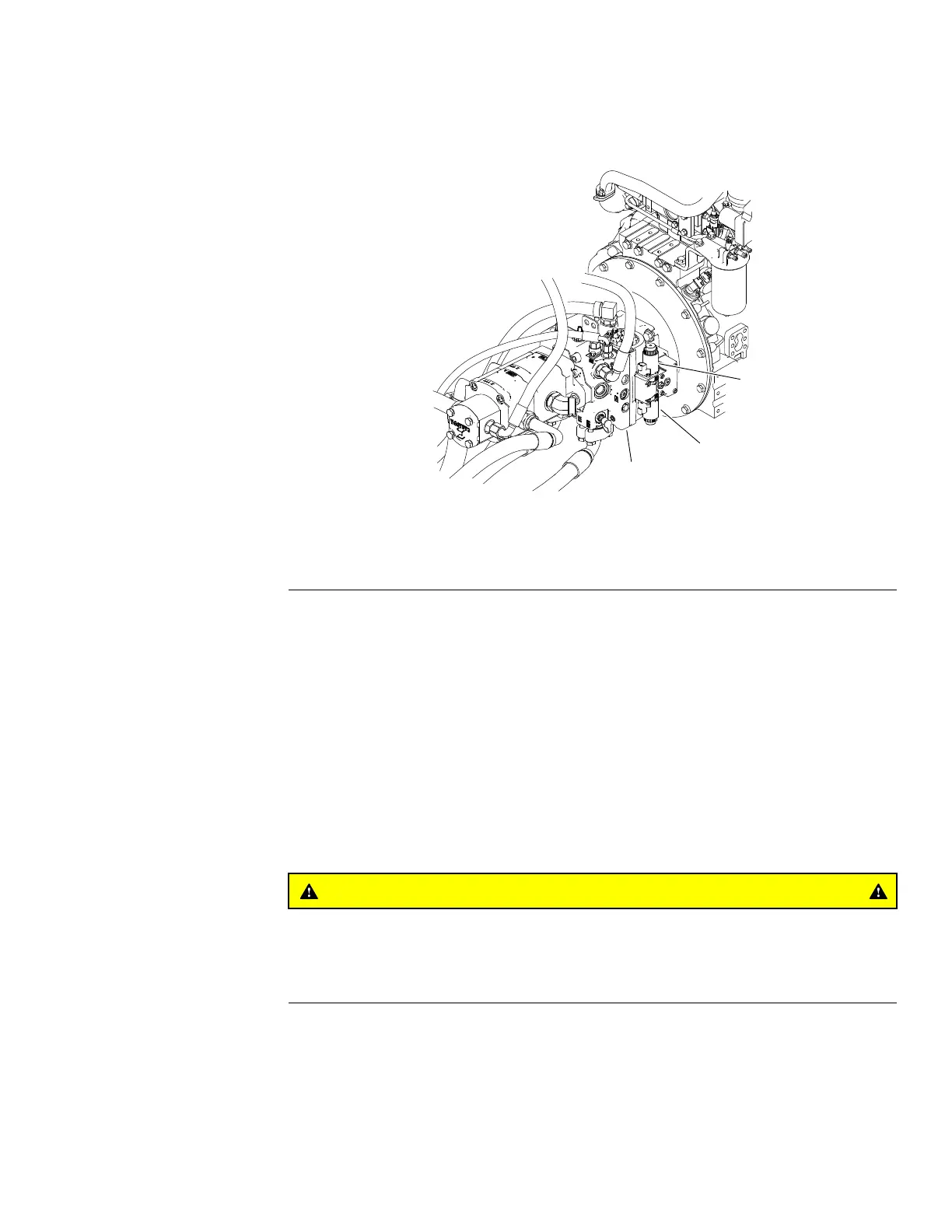

g287906

Figure88

1.Pistonpump

3.Reversesolenoidcoil(S2)

2.Forwardsolenoidcoil(S1)

5.Labelwireharnessconnectorsthatattachtothetwo(2)solenoidcoilson

leftsideofpistonpump(Figure88).Disconnectharnessconnectorsfrom

solenoidcoilsonpistonpump.

6.ReadtheGeneralPrecautionsforRemovingandInstallingHydraulicSystem

Components(page5–73).

7.Forinstallationpurposes,labelallhydrauliclinesthatconnecttogearpump

andpistonpump.

8.Putadrainpanbelowthepumpassembly.Removehydraulichoses

connectedtopistonandgearpumpttings.Putplugsorcapson

disconnectedhydraulichosesandttingstopreventcontaminationofthe

system.

9.Removegearpumpfrommachine(seeGearPump(page5–86)).

CAUTION

Makesurepistonpumpisproperlysupportedbeforeremoving

thepumpmountingscrews.Pistonpumpassemblyweighs

approximately51kg(110lb).

10.Attachhoisttopistonpumptosupportpumpandallowsaferemovalof

pumpfrommachine.

11.Removefour(4)capscrewsandwashersretainingpumpassemblytoengine

ywheelplate.Carefullypullpumpassemblyfromywheelplateandpump

adapterplate(coupler),thenlowerthepumpoutofthemachine.

Groundsmaster

®

5900&5910

Page5–95

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...