Piston(Traction)PumpRemoval(Figure87)(continued)

12.Ifhydraulicttingsaretoberemovedfrompistonpump,marktting

orientationtoallowcorrectassembly.Removettingsfrompumpanddiscard

O−rings.

Piston(Traction)PumpInstallation(Figure87)

1.Ifttingswereremovedfrompistonpump,lubricateandplacenewO−rings

ontottings.Installttingsintopumpopeningsusingmarksmadeduringthe

removalprocesstoproperlyorientatettings.Tightenttings(seeInstalling

theHydraulicFittings(SAEStraightThreadO-RingFittings)(page5–9)).

2.Attachhoisttopistonpumptosupportpumpandalsotoallowsafeinstallation

ofpumpintomachine.

3.Applyantiseizelubricanttointernalsplinesofpumpcouplerandexternal

splinesofpumpshaft.

IMPORTANT

Topreventspringcouplerdamage,makesurethatpistonpumpis

properlysupportedanddoesnotputsideloadoncouplerduring

pumpinstallation.

4.Carefullyraisepistonpumpintothemachine,alignpumpinputshafttospring

coupleronengineandpositionittotheengineywheelplate.Supportpump

topreventitfromproducinganysideloadintocouplerandalsotoalignpilot

diameterofpumptoywheelplatebore.

5.Whilemaintainingpumpalignmentwithspringcouplerandywheelplate,

applymediumstrengththreadlockerandinstallfour(4)capscrewsand

washerstosecurepistonpumptoywheelcoverplate.Tightencapscrews

from115to120N·m(85to89ft−lb).

6.Installgearpumptopistonpump(seeGearPump(page5–86)).

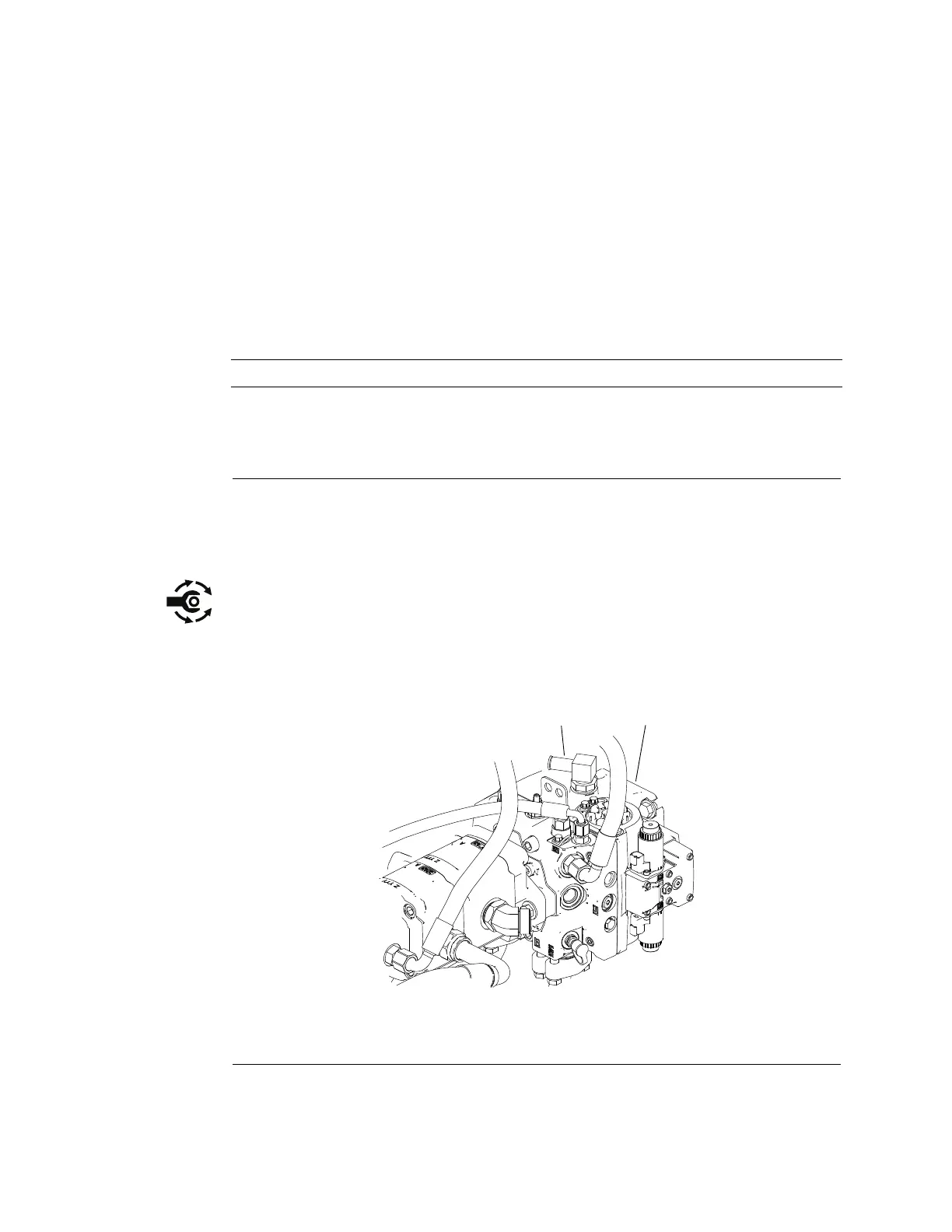

g287907

Figure89

1.Piston(traction)pump

2.Pistonpumpchargereturn

7.Fillpiston(traction)pumphousingwith2.1L(0.55gal)ofnewhydraulic

oilthroughthechargereturn(90obarbedtting)atthetopofthepump

(Figure89).Thiswillensurethatinternalpumpcomponentshaveadequate

lubricationduringinitialoperation.

HydraulicSystem:ServiceandRepairs

Page5–96

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...