TieRodDisassemblyandAssembly

1.Removecotterpinsandslottedhexnutsfromtierodends.Discardcotter

pins.

2.Useasuitablepuller(picklefork)toseparatetierodendsfromthesteering

spindles.

Note:Oneofthetierodballjointshaslefthandthreads.

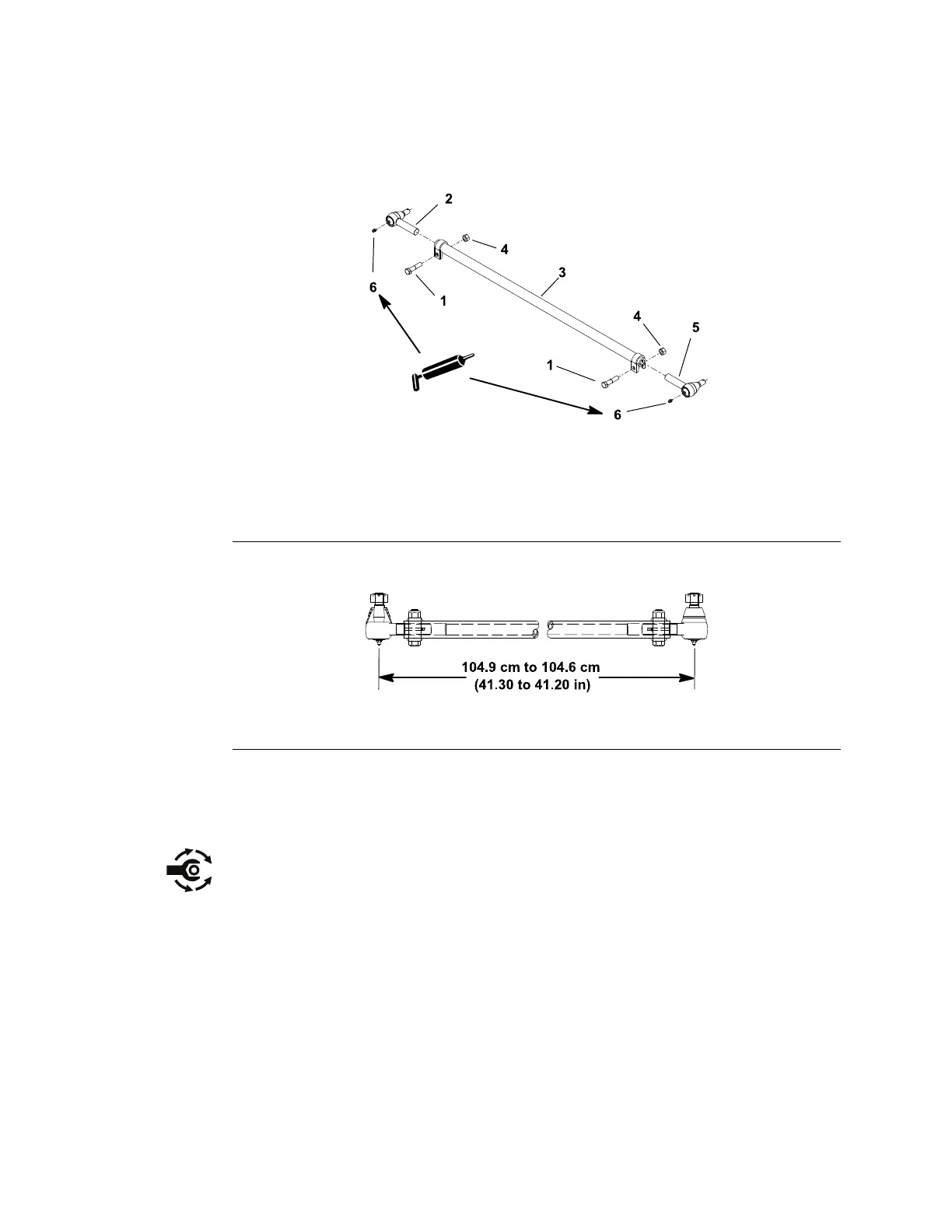

g298846

Figure296

1.Capscrew(2)4.Locknut(2)

2.Tierodend−LHthread5.Tierodend−RHthread

3.Tierodtube

6.Greasetting(2)

3.Loosentheclampcapscrewsandlocknutsthenunscrewballjointsfrom

tierod(Figure296).

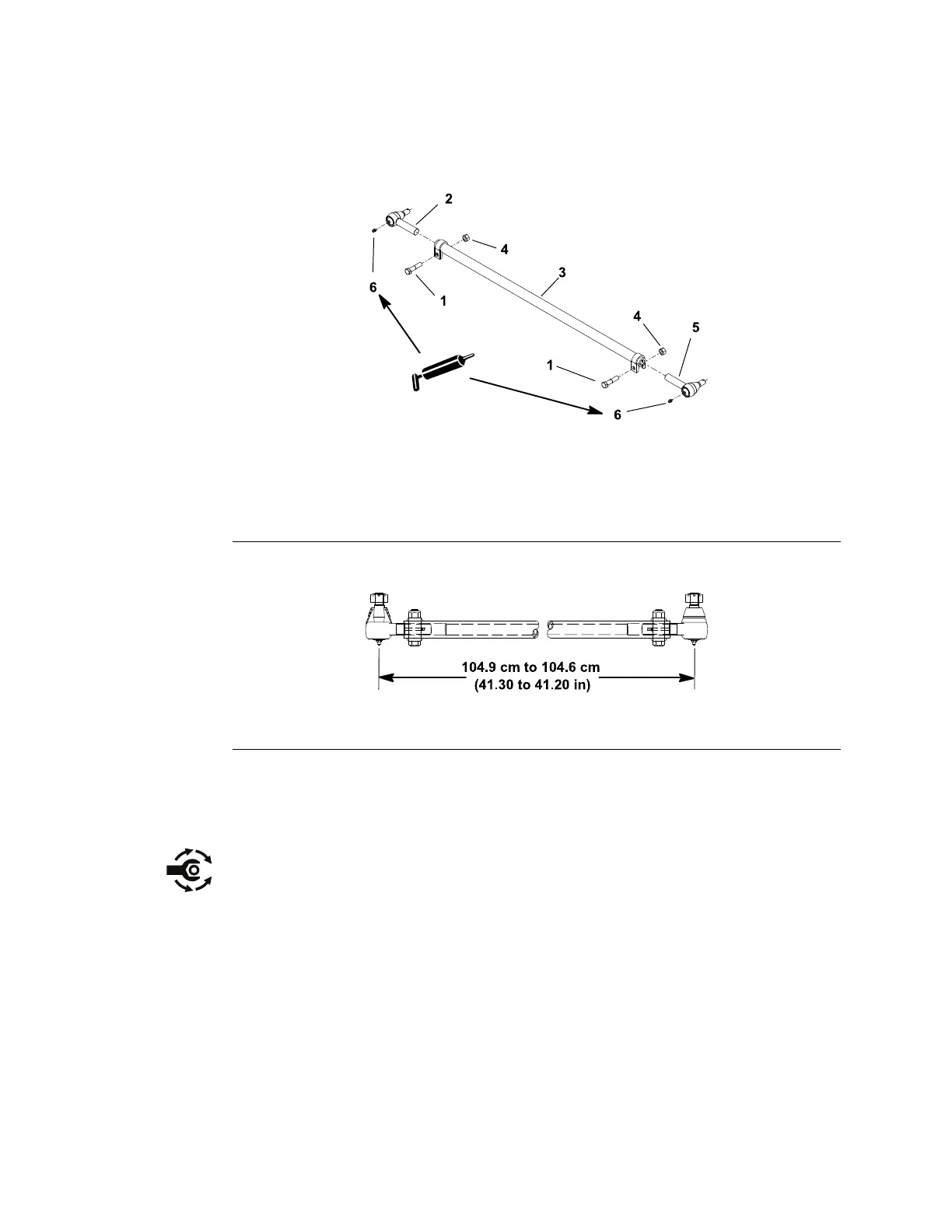

g298847

Figure297

4.Threadballjointsequallyintotierodsothatcentertocenterlengthisfrom

104.9to104.6cm(41.30to41.20in)(Figure297).

5.Thoroughlycleanthetaperedsurfacesofthetierodballjointsandsteering

spindles.

6.Connectthetierodendstothesteeringspindleswithslottedhexnuts.

Torquenutfrom40to61N·m(30to45ft−lb).Installcotterpin.

7.Checkandadjustrearwheeltoe−in(seemachineOperator’sManual).

8.Lubricatethetierodballjoints.

9.Checktomakesurethatnocontactismadebetweenanymachine

components(includinghydraulichoses)astherearwheelsaremovedfrom

steeringlocktosteeringlock.Correctanyinterferenceasnecessary.

Chassis:ServiceandRepairs

Page7–14

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...