JointYokeAssembly(continued)

g298933

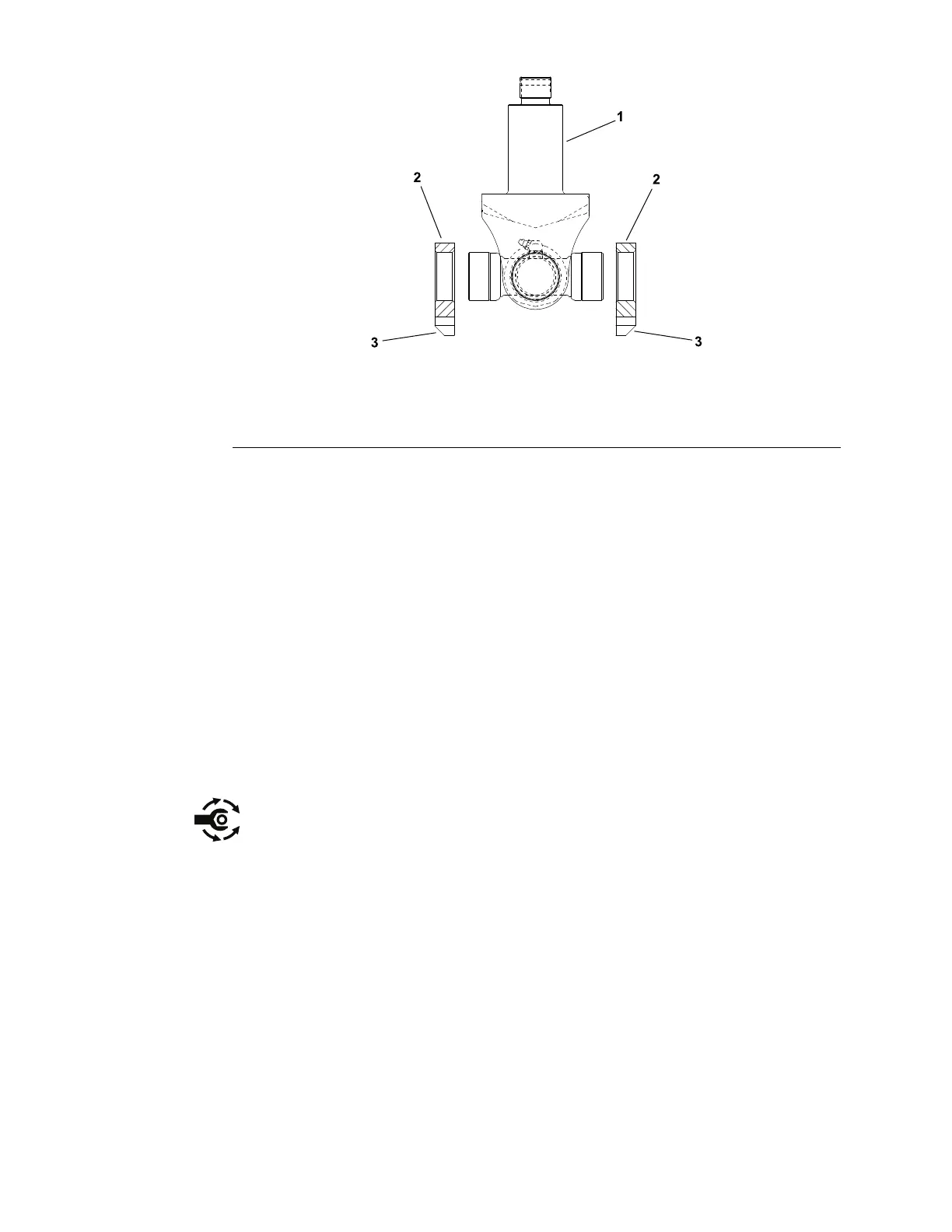

Figure309

1.Jointyoke3.Anglededge

2.Basemount

8.Pressbasemountsontobearingcapswiththeanglededgeofthemounts

awayfromthejoint(Figure309).Theoutsideofthecrossbearingcups

shouldbeushwiththebasemountsurfaces.

9.Makesurethatassembledjointyokemoveswithoutbinding.Slightbinding

canusuallybeeliminatedbylightlyrappingtheyokelugswithasoftfaced

hammer.Ifbindingcontinues,disassemblejointyoketoidentifyandeliminate

sourceofbinding.

JointYokeInstallation(Figure307andFigure308)

1.Installjointyoketoliftarm:

A.Placespacer(item7)andthenthrustwasherontojointyokeshaft.

B.Insertyokeshaftupthroughliftarmbushings.

C.Placethrustwasher(item6)ontojointyokeshaftandthenplace

washer(s)(item5)asneededtoremoveasmuchclearanceaspossible

betweenthethrustwasherandthehardenedwasher(item4).

D.Installslottedhexnuttosecurejointyoketoliftarm.T orquenutfrom

204to244N·m(150to180ft−lb).Makesurethatjointyokerotatesin

liftarmwithoutbindingandthatexcessiveclearancedoesnotexistin

yokeassembly.

2.Carefullylowerliftarmtopositionbasemountstodeckconnection.

3.Installshimsbetweendeckconnectionandbasemounts.Securebase

mountswitheight(8)capscrews,hardenedwashersandtwo(2)boltplates.

Tightencapscrewsfrom53to64N·m(39to47ft−lb).

4.Greasejointyokeandliftarmbushingafterinstallationonmachine.

5.Afterassemblyiscompleted,raiseandlowerthecuttingdecktoverifythat

hydraulichosesandttingsdonotcontactanythingthroughoutthefullrange

ofmovement.

Chassis:ServiceandRepairs

Page7–30

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...