BladeSpindleDisassembly(Figure333)(continued)

3.Removeanddiscardtheoilsealsfromspindlehousing.

4.Removethebearingcones,innerbearingspacer,spacerringandspindle

shaftO−ringfromthespindlehousing.DiscardthespindleshaftO−ring.

5.Usinganarborpress,removebothofthebearingcupsandtheouterbearing

spacerfromthehousing.

6.Thelargesnapring(item13)canremaininsidethespindlehousing.

Removalofthissnapringcanbeverydifcult.

7.Removedamageddrivestuds(item16)asneeded.

BladeSpindleAssembly(Figure333)

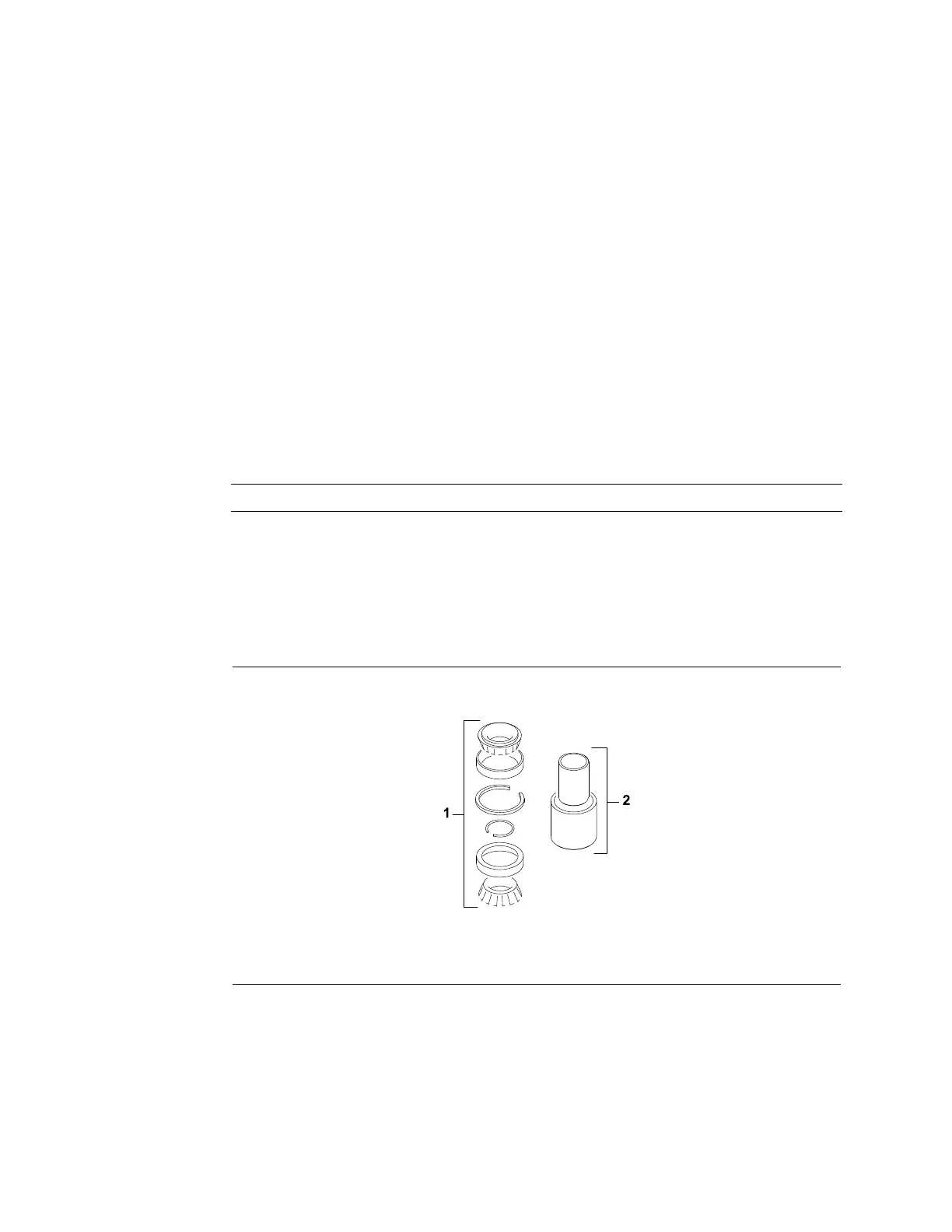

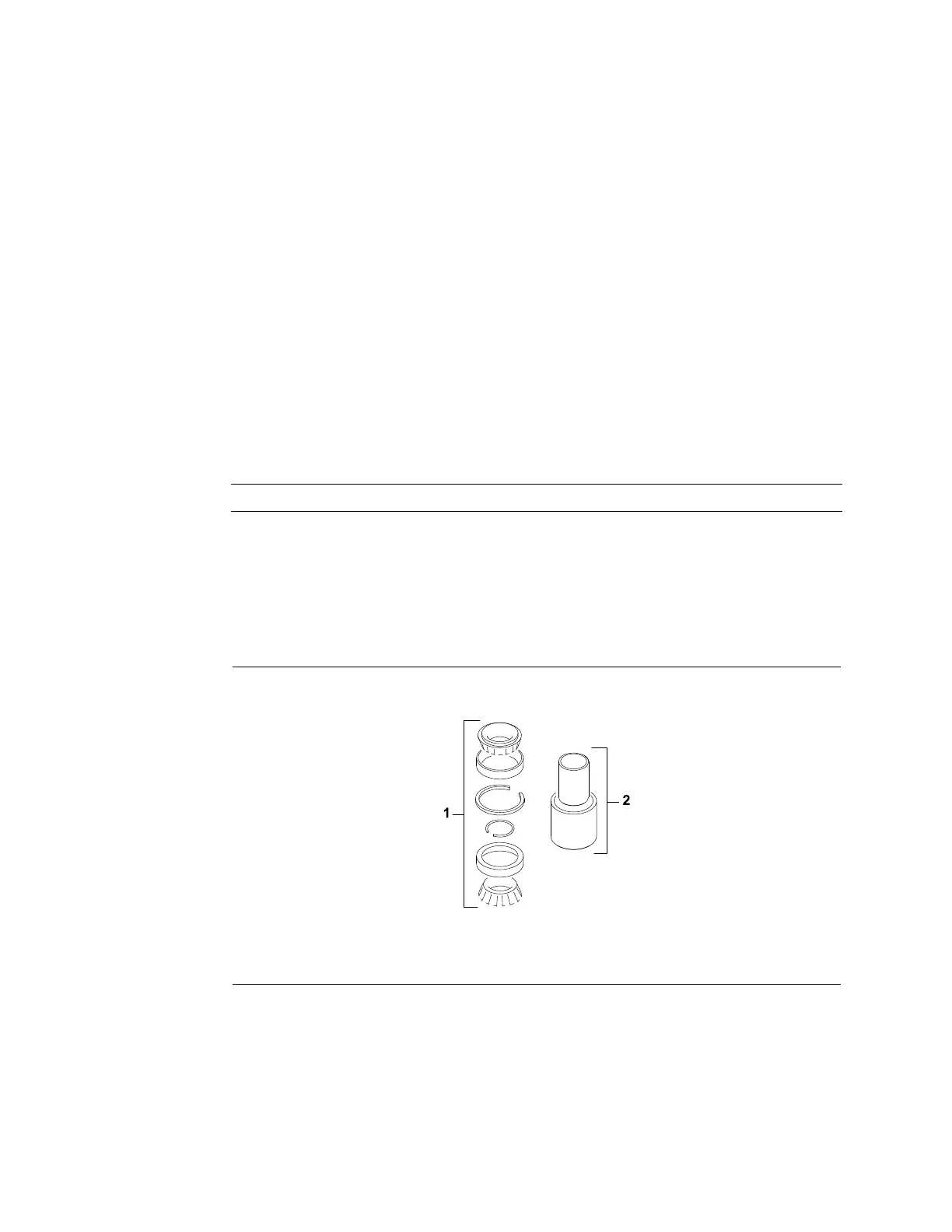

Note:Areplacementspindlebearingsetcontainstwo(2)completebearings

(cupsandcones),aspacerringandalargesnapring(Figure334).Theseparts

cannotbepurchasedseparately.DoNotmixbearingsetcomponentsfromone

deckspindletoanother.

Note:Areplacementbearingspacersetincludestheinnerspacerandouter

spacer(Figure334).Thesepartscannotbepurchasedseparately.DoNotmix

bearingspacersfromonedeckspindletoanother.

IMPORTANT

Ifnewbearingsareinstalledintoausedspindlehousing,itmaynot

benecessarytoreplacetheoriginallargesnapring(item13).Ifthe

originalsnapringisingoodconditionwithnoevidenceofdamage

(e.g.spunbearing),leavethesnapringinthehousinganddiscard

thesnapringthatcomeswiththenewbearings.Ifthelargesnap

ringisfoundtobedamaged,replacethesnapring.

1.Useanarborpresstoinstallanydrivestudspreviouslyremoved.

g299694

Figure334

1.Bearingset

2.Spacerset

2.Iflargesnapring(item13)wasremovedfromthespindlehousing,installthe

snapringintothehousinggroove.Makesurethesnapringisfullyseatedin

thehousinggroove.

3.Installouterbearingspacerintotopofspindlehousing.Thespacershould

contactthelargesnapring.

CuttingDecks:ServiceandRepairs

Page8–18

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...