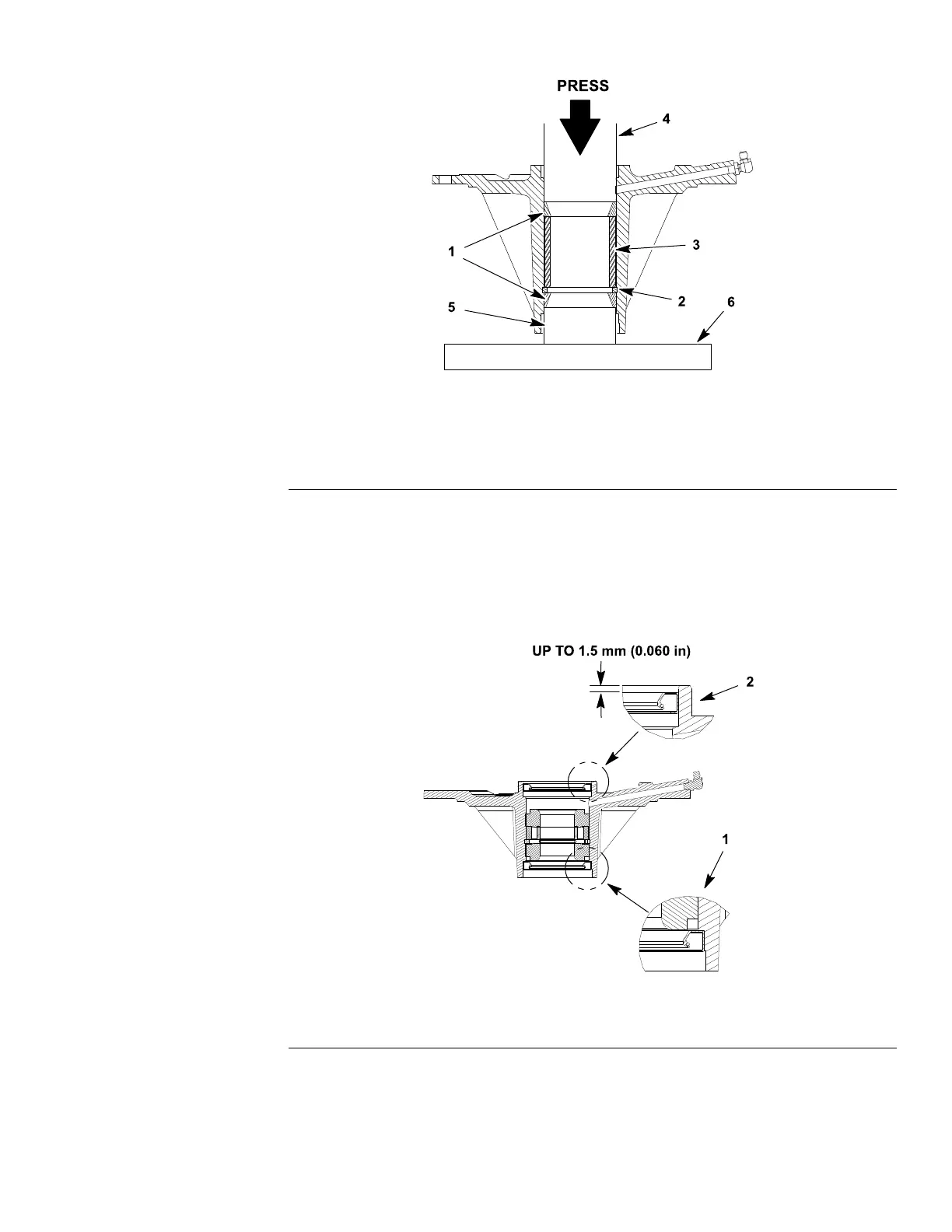

BladeSpindleAssembly(Figure333)(continued)

g299695

Figure335

1.Bearingcups4.Arborpress

2.Largesnapring

5.Support

3.Largeouterspacer6.Arborpressbase

4.Usinganarborpress,pushthebearingcupsintothetopandbottomofthe

spindlehousing.Thetopbearingcupmustcontacttheouterbearingspacer

previouslyinstalled,andthebottombearingcupmustcontactthelargesnap

ring.Makesurethattheassemblyiscorrectbysupportingtherstbearing

cupandpressingthesecondcupagainstit(Figure335).

5.Packthebearingconeswithgrease.Applyalmofgreaseonlipsofoil

sealsandO−ring.

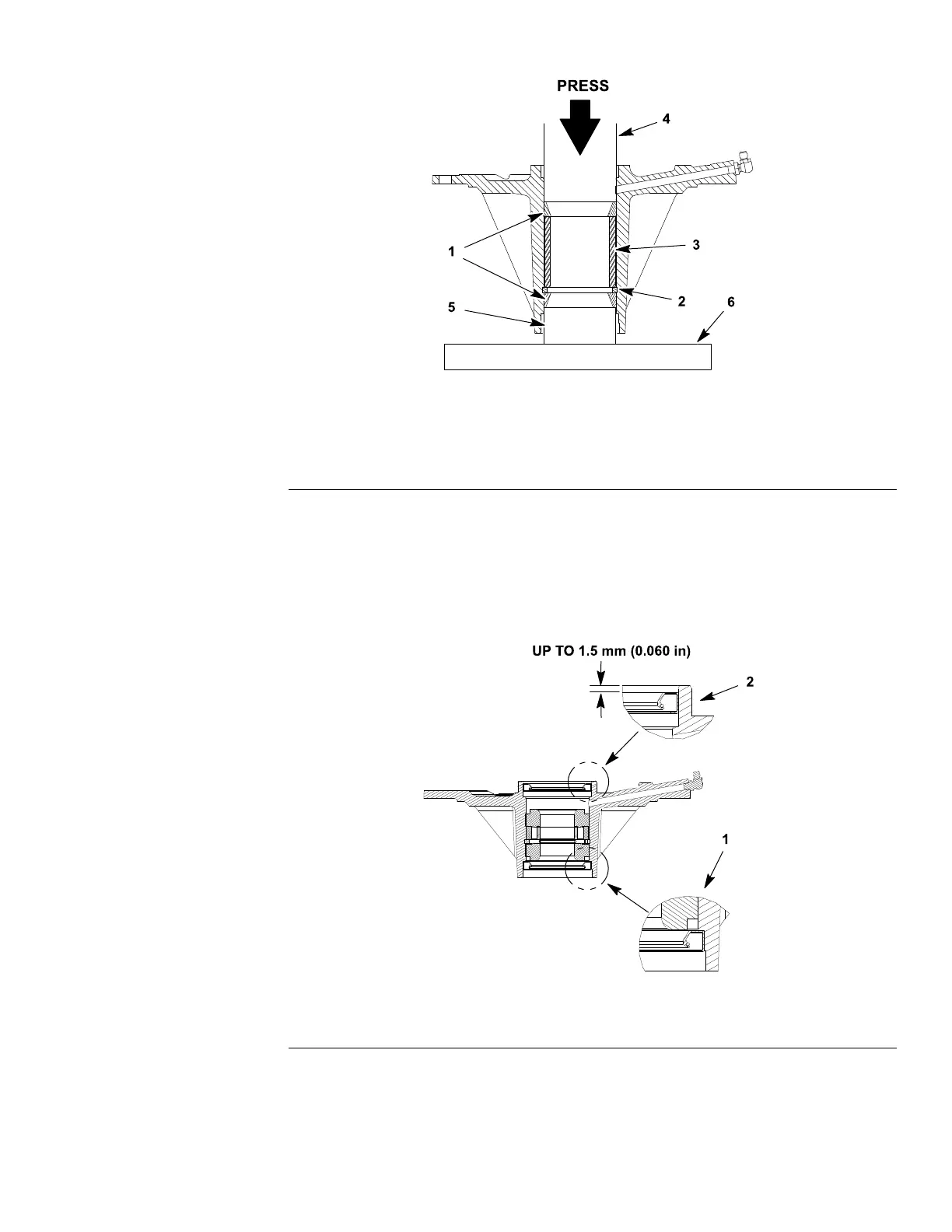

g299696

Figure336

1.Bottomsealinstallation2.Uppersealinstallation

6.Installlowerbearingconeandgreasedoilsealintobottomofspindle

housing.Note:Thebottomsealmusthavethelipfacingout(down)(Figure

336).Thissealinstallationallowsgreasetopurgefromthespindleduring

thelubricationprocess.

Groundsmaster

®

5900&5910

Page8–19

CuttingDecks:ServiceandRepairs

16227SLRevB

Loading...

Loading...