Chapter 4 Maintenance

HA-8190V 4-48

3 Remove air from the column by priming.

a Touch and wait about 30 seconds.

• Fluid pumping starts, and liquids and bubbles overflow from the

connection between the column and push screw.

• Continue pumping until bubbles disappear and only fluid

overflows.

• The <Pressure> value will be near “0 kg/cm

2

”.

b With liquid overflowing from the IN side, securely tighten the IN-side push screw by hand and immediately wrap

the OUT side of the column with tissue paper.

• Liquid will overflow from the OUT side of the column.

• The <Pressure> value will gradually rise and level off at about half the pressure indicated on the “CERTIFICATE

OF QUALITY”.

4 Tighten the column fully.

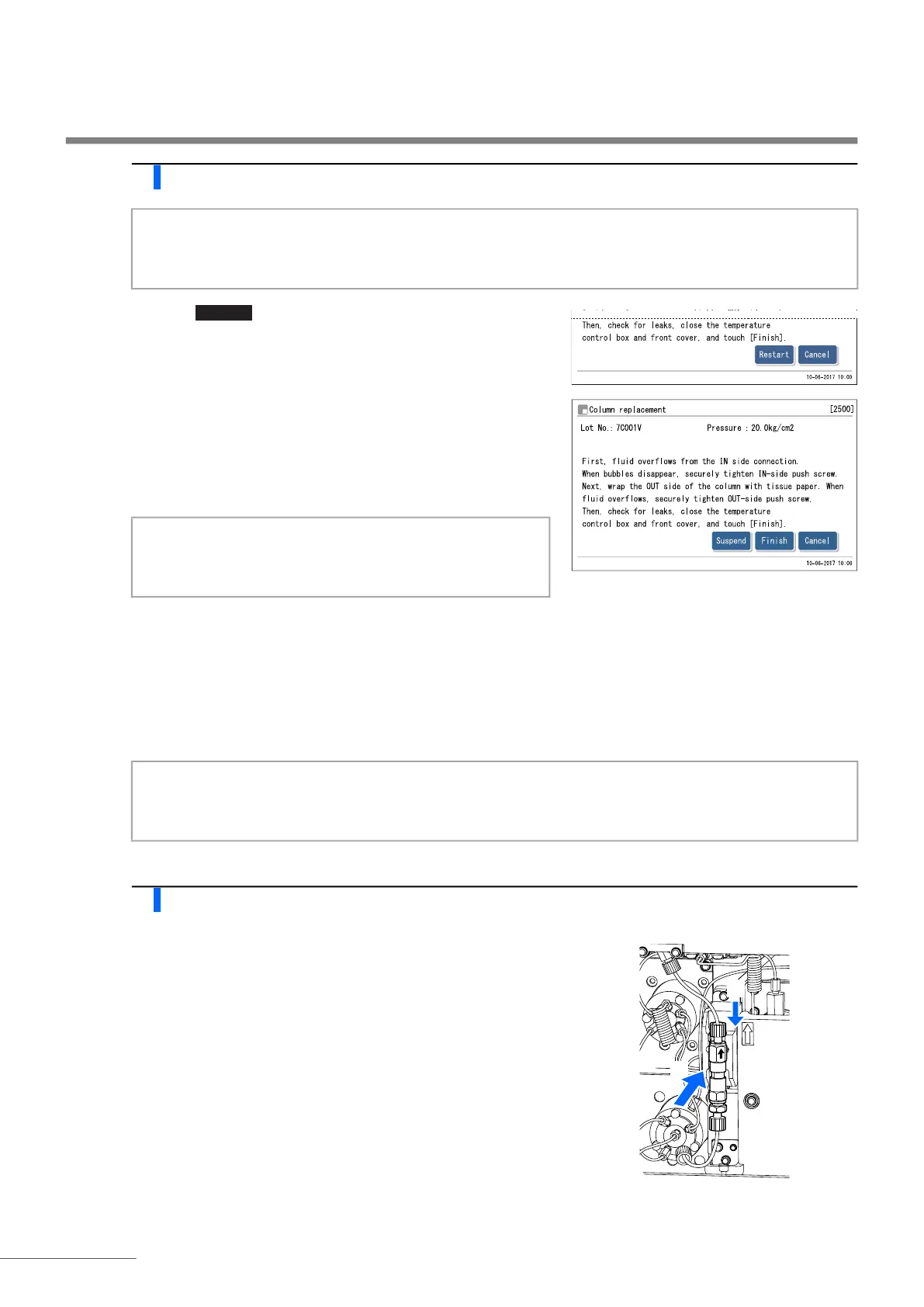

a Connect the push screw to the OUT side of the column.

• Insert the tube of the push screw into the column until the tube

stops, and then securely tighten the push screw by hand.

b Remove the tissue paper.

c Install the column into the column holder.

d Check that liquid does not leak from the connections on the IN

and OUT sides of the column.

• Retighten the push screws if liquid leaks.

e Close the temperature control box cover, then the front cover.

NOTE:

Before starting fluid pumping, ensure that the tube is inserted into the IN side of the column. If the tube is not

inserted enough, fluid may splatter during pumping.

NOTE:

Slightly loosen the push screw if liquid does not overflow

from the connection.

NOTE:

Tighten the push screw while fluid is overflowing. Bubbles remaining in the connection may cause abnormal

chromatograms.

Loading...

Loading...