121

Bruker Optik GmbH IFS 125M User Manual

Maintenance 6

4 • Loosen the clamp screw located between

the two spring-loaded bolts (5 in figure

6.9).

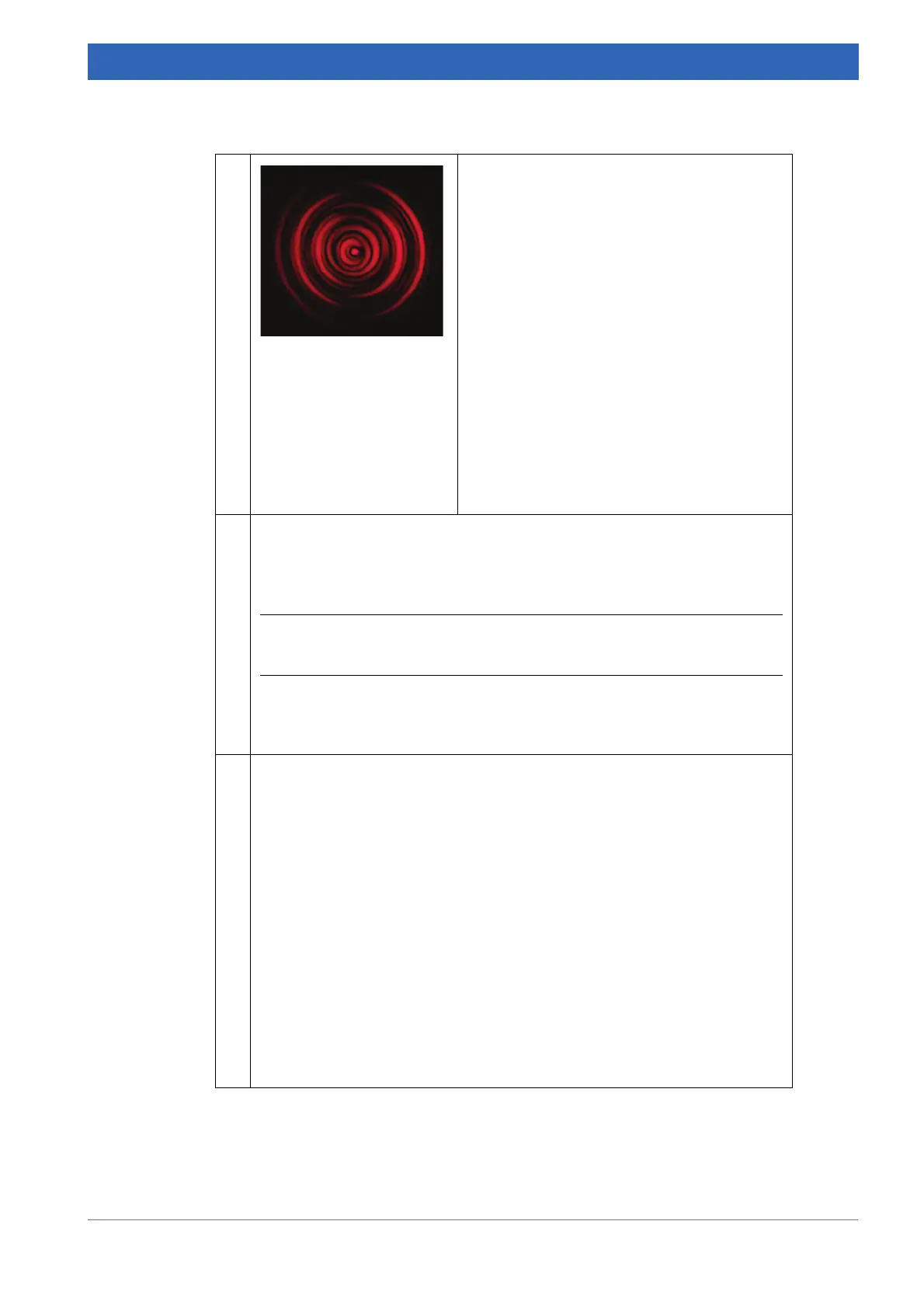

• Adjust screws (4 in figure 6.9), which causes

a x-y shift, so that the observed diffraction

pattern is at maximum brightness.

☞ If required, re-adjust the pre-load by

means of screws (5).

• Adjust screws (1 in figure 6.9), which causes

a tilt, to achieve a (nearly) concentric diffrac-

tion pattern.

☞ If the pre-load of any screw (1) gets too

high or too low, the tension can be cor-

rected by means of the screw (2) which is

diagonally opposite.

• If necessary, the x-y and tilt adjustments

have to be repeated.

• Remove the alignment tool.

5 • Mount the fiber patch cord.

➣ As the fiber is very sensitive, be careful by putting the fiber on the cou-

pler. Do not use too much force and turn the fiber slightly (at the plug)

while guiding the ferrule into the socket.

i The whole receptacle is mounted at a 3.5° angle, so the ferrule must be

tilted at that angle, too.

• Make sure that the key at the plug points into the direction of the notch at

the receptacle.

• Fix the lock nut only hand-tight.

6 You should see a light beam (at least dim) emitting out of the fiber. You can

watch the beam on a white piece of paper.

• If available, mount the fiber collimator tool with integrated polarizer and Si-

diode at the fiber end.

• Rotate the integrated Si-diode until a maximum intensity is read. Lock the

position. If the tool is not available, use the power-meter or Si-diode to

monitor the intensity (P

out

).

• Turn screws (4) slightly one by one to increase the intensity.

☞ If required, re-adjust the pre-load by screws (5).

• Adjust the tilt of the coupler. Use screws (1) one by one to change the tilt

and maximize the intensity.

☞ If required, re-adjust the pre-load by the screw (2) located diagonally

opposite.

• Repeat the x-y and tilt adjustments successively until you achieve a power

P

out

a

, which is at least 65% of P

in

b

.

Table 6.31: Readjusting fiber-coupling head

Loading...

Loading...