6

Sync Camera Assembly

Ball Detect Calibration Instructions

WARNING: Before adjusting the ball detector, turn the stop/run switches on the

pinsetter to the stop position. Failure to do this may result in personal injury

caused by pinsetter cycling when the ball detect’s beam is interrupted or the

pinsetter is turned on at the Control Desk.

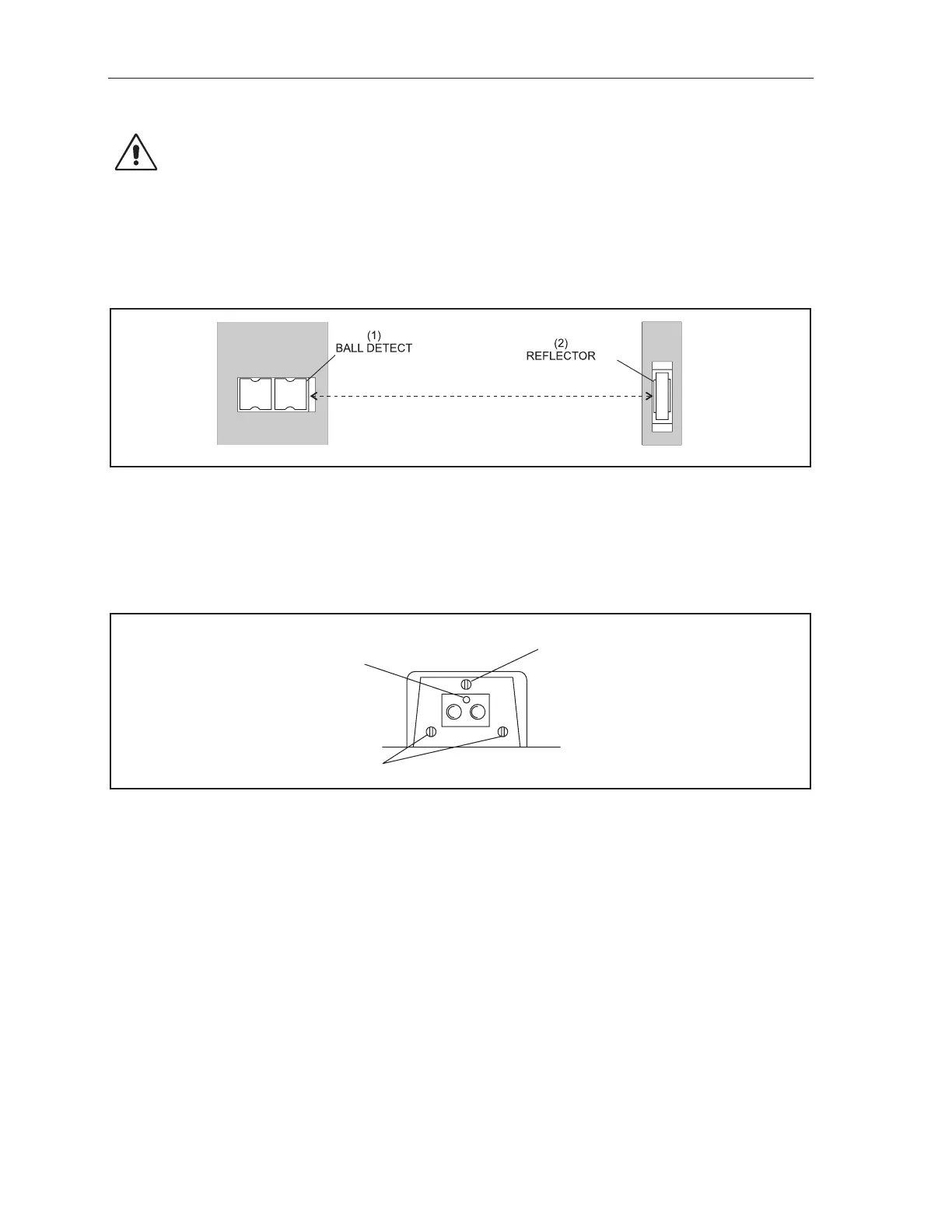

The ball detect adjustment contains three screws that are used to align the units infrared beam with a

reector opposite side of the lane. Refer to the gure titled Ball Detect and Reector.

Ball Detect and Reector

(1) BALL DETECT (2) REFLECTOR

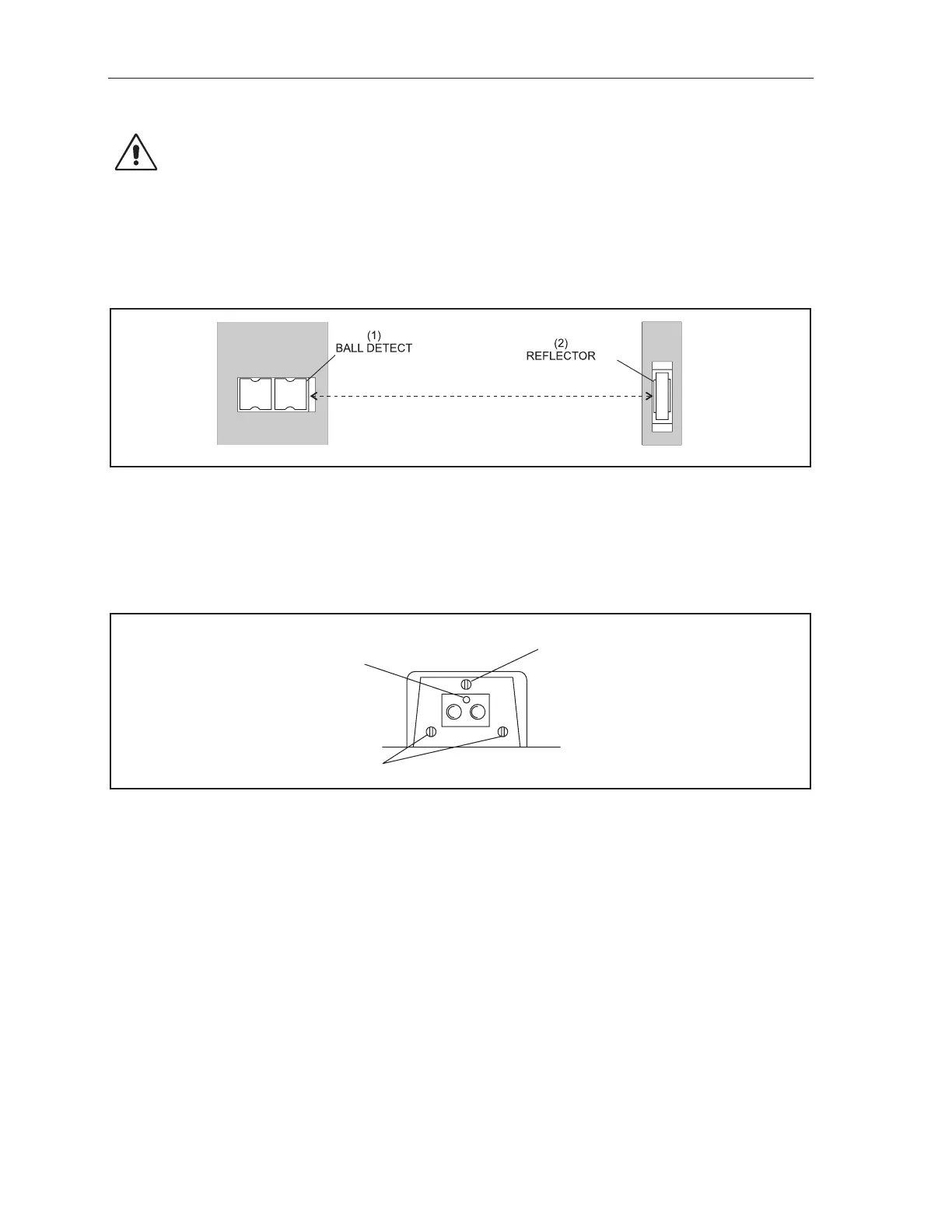

The red LED (Light Emitting Diode) mounted on the ball detect is “on” when the beam is not being

received back from the reector. This indicates a ball or some object is in the beam’s path or there is an

alignment problem. Refer to the gure titled Ball Detect Adjusting

(1)

VERTICAL

ADJUSTING SCREW

(2)

RED LED

(3)

HORIZONTAL

ADJUSTING SCREW

Ball Detect Adjusting.

(1) VERTICAL ADJUSTING SCREW (2) RED LED (3) HORIZONTAL ADJUSTING

SCREW

1. Check the face of the ball detect and make sure it is parallel with the face of the ball detect’s

housing. Check the reector to see if it is mounted securely and parallel to the ball detect. Clean

the transmitter, receiver and reector before and after adjusting.

2. Cover the reector with a dark non-reective object. The red LED should be lit indicating the

beam is not being received.

3. Hold an unmounted reector in your hand and move it above, below and around the mounted

reector until the red LED goes “off.” This will indicate the position of the beam and guide you

in your adjustment.

4. Using the vertical and horizontal adjusting screws (refer to the gure titled Ball Detect

Adjusting) move the beam until it is aimed exactly on the center of the mounted reector.

Loading...

Loading...