FI002K0018v1100UK – THS/21 Instruction manual for installation, use and maintenance

3

INSTALLATION

ORIGINAL INSTRUCTIONS 103

3.8.6 Encoder

Variable speed conveyor belts must be fitted with an encoder. In this case the delay in activating

the ejection step is calculated dynamically as a function of the speed measured. It is also possible

to control the speed of the conveyor belt continuously so that it is always between BL and BM.

Programming menu

Remote

parameter

Description Setting

Configuration(adv) > K encoder

KE

Pulses per encoder revolution

(PPR)

1000 pulses/rotation

max

Configuration(adv) > Diameter

DI

Diameter

10 - 250 mm

The diameter DI refers to the diameter of the encoder wheel or to the diameter of the drive roller to

which it is fixed, increased by twice the thickness of the belt.

Given the maximum speed of the line (Vmax in m/min), the encoder must be set for a number of

pulses per rotation (PPR) as defined by this formula:

max

180

V

DI

PPR

Enter the I/O Status > Measures menu and verify, using a tachymeter, that the speed measured

(Speed) corresponds to the current one.

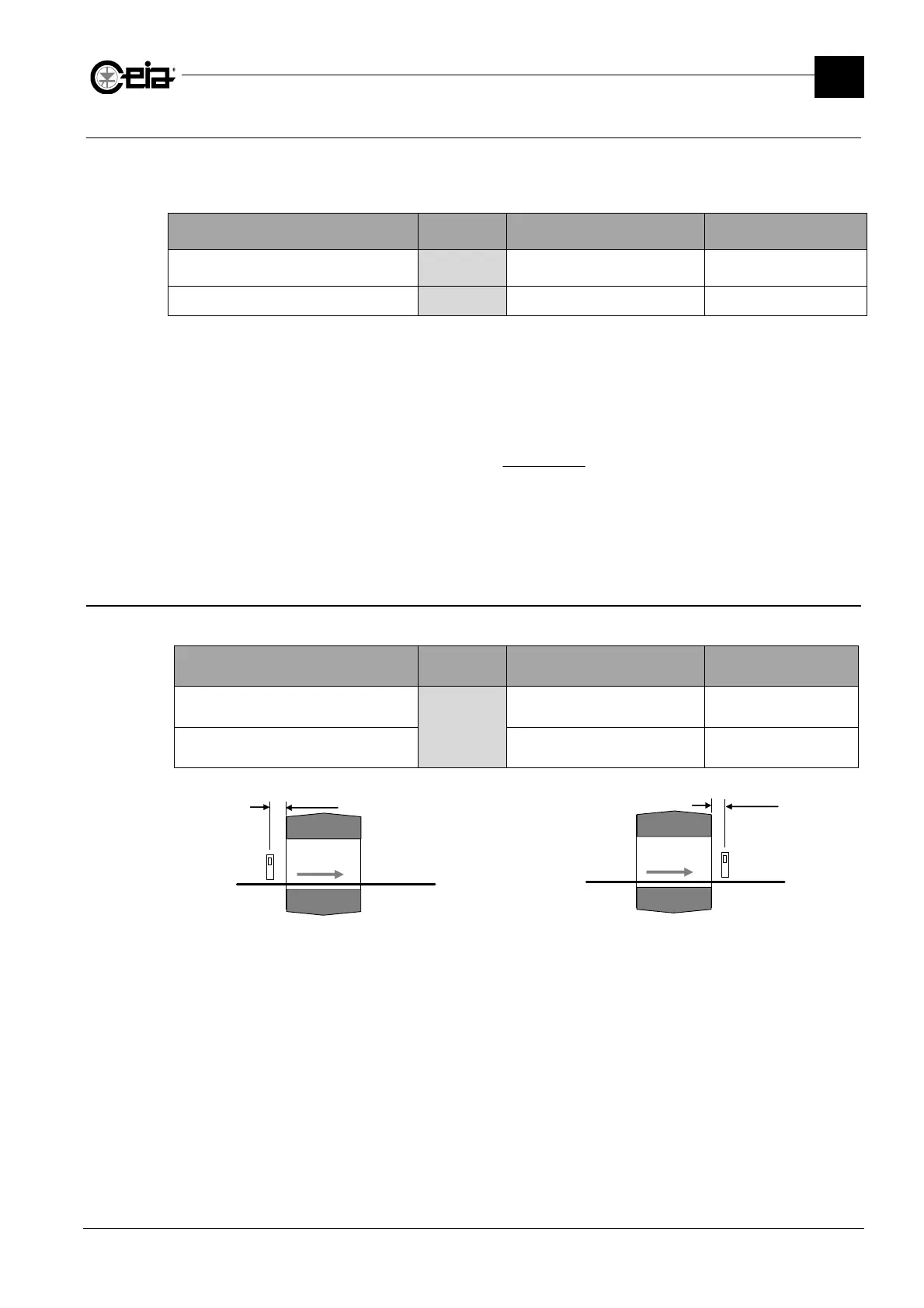

3.8.7 Synchronization photocell

The Synchronization photocell must be programmed as described below:

Programming menu

Remote

parameter

Description Setting

Configuration(adv) > Position pcell

PH

Position of the photocell relative

to the probe

IN / OUT

Configuration(adv) > Dist. Pcell-MD

PD

Distance between the Metal

Detector and the photocell

0 - 2000 mm

F

S

N

PD

F

S

N

PD

Photocell installed at the entrance

Photocell installed at the exit from the probe

N: conveyor belt; S: electronics unit; F: photocell; PD: distance photocell- electronics unit

Loading...

Loading...