FI002K0018v1100UK – THS/21 Instruction manual for installation, use and maintenance

3

INSTALLATION

ORIGINAL INSTRUCTIONS 55

Applications at high speed (belt speeds greater than 60 m/min) (EM=FS)

In this case, the response times of the photocell, the Metal Detector and the ejector cannot be

ignored. We would generally advise users to check operation of the ejector through trial and error,

changing its position and adjusting parameter ED.

3.1.3 Installation guidelines for correct environmental compatibility of the Metal Detector

Possible sources of electrical interference may be power supply cables (electromagnetic fields

generated by alternating currents) or pulsing electromagnetic sources (electrical motors with

high start-up power absorption and their power supply cables, fluorescent lights, emergency

generators, remote control devices, etc.) located near the probe.

3.1.3.1 Power supply and control cables of other devices.

- Use sheathed power supply cables or interweave the conductors with the shortest possible

spacing.

- Keep the power cables as far as possible from the Metal Detector; otherwise, it is advisable

to put them in a metal conduit connected to earth on one side only and appropriately

fastened to prevent vibrations.

- Do not connect in any way power supply cables of other devices inside the Metal Detector

power supply box.

- Where possible, move the power cables away from cables of devices connected as inputs to

the Metal Detector (e.g. encoder) or screen them with a metal conduit connected to earth on

one side only.

3.1.3.2 Pulsed-type sources

- Move as far away as possible from the Metal Detector devices which might generate pulsed-

type disturbances, e.g. motors, inverters, electricity supply boards, electromagnetic actuators

(they should be replaced with similar pneumatic devices), fluorescent lights and related

starters (where possible, replace them with a filament bulbs).

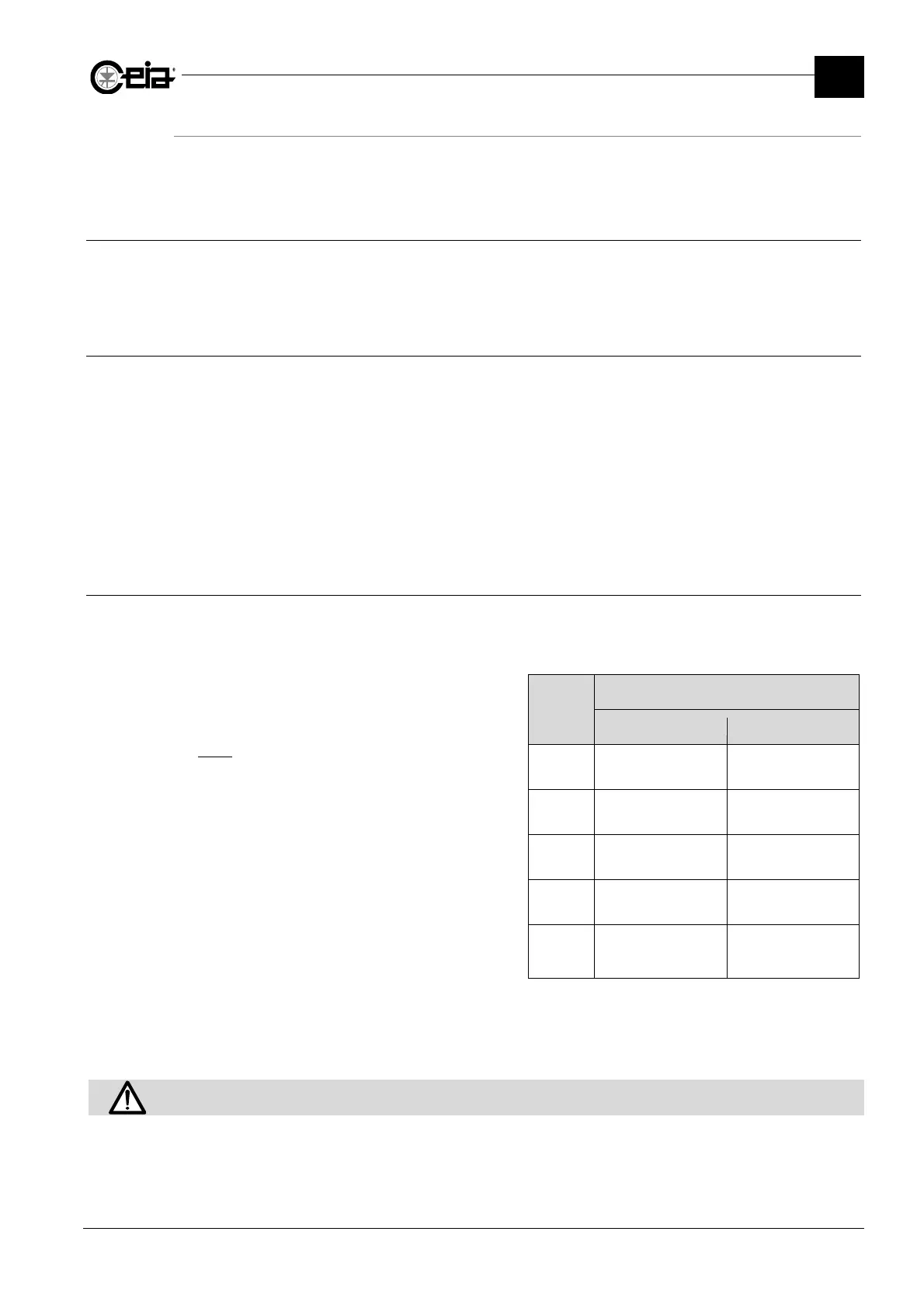

- Provide electric motors with mains filters and

keep a minimum distance between the Metal

Detector and the motor, as indicated in the

table

based on the power of the motor.

Where possible, AC motors should be used

rather than DC motors.

- If they are installed near the Metal Detector,

the motors should be screened with

cylindrical steel (non-welded) enclosures no

less than 2 mm thick.

- Provide the electromagnets, remote control

switches and DC motors with dampening

circuits and interweave the relative power

supply cables with the shortest possible

spacing.

Power

(CV)

Minimum distance

THS/MN21 Other THS models

0,5

5 x DH

3 x DH

1

6 x DH

4 x DH

2

8 x DH

5 x DH

3

10 x DH

6 x DH

20

15 x DH

(10 x DH if screened)

10 x DH

(6 x DH if screened)

- Provide each inverter with filters or inductors at their infeed, selected based on the inverter

specifications.

- Provide the connection cable to the motor with a ferrite to be placed near the inverter,

passing one or more coils of the phase conductors through the ferrite itself.

Fix the probe cable to the power supply unit so that it cannot oscillate or vibrate.

If the cable is too long, DO NOT CUT THE CABLE: COIL UP THE EXCESS.

Loading...

Loading...