FI002K0018v1100UK – THS/21 Instruction manual for installation, use and maintenance

3

INSTALLATION

ORIGINAL INSTRUCTIONS 51

3.1.2.3 Customer conveyor belt

3.1.2.3.1 Load-bearing structure

During assembly the solidity of the load-bearing structure should

be borne in mind, in order to ensure that the detector does not

oscillate, causing false alarms.

The load-bearing structures of the conveyor belt must be stable

and not subject to detectable vibration when the belt is moving.

For a THS/MN21 the structure of the belt must be in non-

magnetic steel (e.g. AISI 316).

Welded metal structures are preferable. If the frame, or parts of it,

is screwed, insulate each contact between metal parts.

Make sure that the metal crossbeams of the frame are as far as

possible from the probe opening and, in any case, at no less than

the minimum distance required for fixed metal parts.

3.1.2.3.2 Side panels to contain the material in transit

Any side panels near the probe must be made of insulating

material (plastic, wood, etc.).

Side panels to contain the material in transit

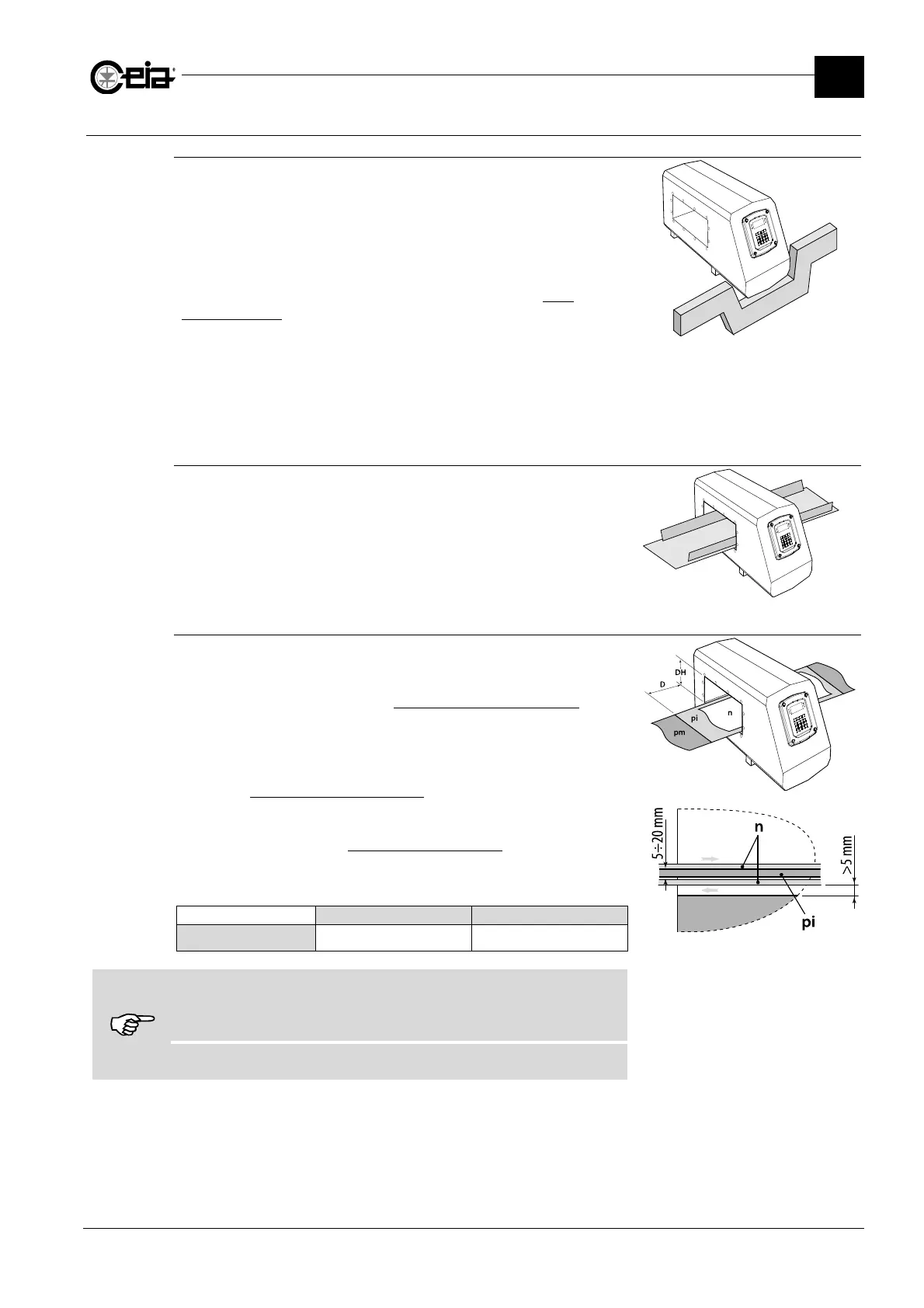

3.1.2.3.3 Position of the conveyor belt inside the probe

The conveyor belt must run as close as possible to the lower

surface of the tunnel. In order to prevent it from accidentally

rubbing against the probe it is advisable that it be supported

within the probe by means of a sheet of insulating material

, which

is thick enough to support the weight of the material being

transported (approximately 5-20 mm).

This is particularly important with long belts which, in addition to

requiring extra support, must also be prevented from vibrating.

The sheet must not touch the probe

(the figure shows a gap of 5-

10 mm); if it were to touch the probe it could send vibrations to

the probe.

In any case, if there is a supporting metal layer

for the belt, when

it arrives at the probe, it must be interrupted for a distance D, on

both sides of the probe.

All models THS/MN21

D

2 DH 4 DH

For products in metalized packs with the THS/21x antenna or contents in

aluminium trays with THS/MN21 antennas, the optimum distance of the belt

(from the bottom of the probe) is the distance which guarantees that the

product passes totally centred on the probe opening.

For flat belts, the conveyor belt must pass through the probe in both directions

to avoid having to cut and re-join it when substituting the belt.

Position of the conveyor belt inside

the probe

pi: sheet of insulating material;

pm: layer of metal material;

n: belt

Loading...

Loading...