FI002K0018v1100UK – THS/21 Instruction manual for installation, use and maintenance

5

MAINTENANCE

ORIGINAL INSTRUCTIONS 151

5.5.3 Checking belt contamination

This check can only be done with conveyor belt systems and BLEN>0.

This command performs a complete set of automatic checks to verify the state of contamination of

the conveyor belt integrated with the Metal Detector, in normal operating conditions and without

product in transit.

- Access programming in the

Configuration > Compatibility chk

menu and check that the

full extended length of the belt has been set correctly in

Belt length

.

- Access the

Configuration > Compatibility chk > Belt contam.check

menu and press the

E key to start the procedure. The Metal Detector will ask to stop or start the conveyor belt,

according to the sequence given below:

Step 1 Step 2 Step 3 Step 4

Transport stopped Transport stopped Transport running Transport running

During the procedure the execution of more steps may be requested.

At the end of the procedure the Metal Detector will show the estimated level of belt contamination:

VERY HIGH, HIGH, LOW, NO CONTAMINATION.

This result takes account of the current Metal Detector settings, but a check still needs to be made

that it also works properly with product in transit. If there is a mechanical or electrical disturbance,

the Metal Detector gives the message that the belt contamination state cannot be shown and that

the general compatibility of the Metal Detector must be assessed first (IMPROVE

COMPATIBILITY).

If there is a CEIA conveyor belt, refer to the section of the Installation Manual on removing the belt.

5.5.4 General or electrical compatibility checks result

For each step the procedure records the peak (pk) and the average (av) value of the signal read by

the Metal Detector. In case of SUFFICIENT or INSUFFICIENT results, and based on the measured

data values, the Metal Detector can give also an indication on how to fix some of the noises

detected:

-

Improve electromagnetic compatibility

: electrical noise in the installation environment.

-

Improve transport electromagnetic compatibility

: electrical noise due to the transport

system or to a machine activated during the compatibility check procedure.

-

Improve transport general compatibility

: electrical and/or mechanical noise due to the

transport system or to a machine activated during the compatibility check procedure.

If the Metal Detector does not give any indication, the nature of the detected noise can be located

using the indicative table below. For each step, the peak value and the average value can suggest

if the noise is due to transient effects or not.

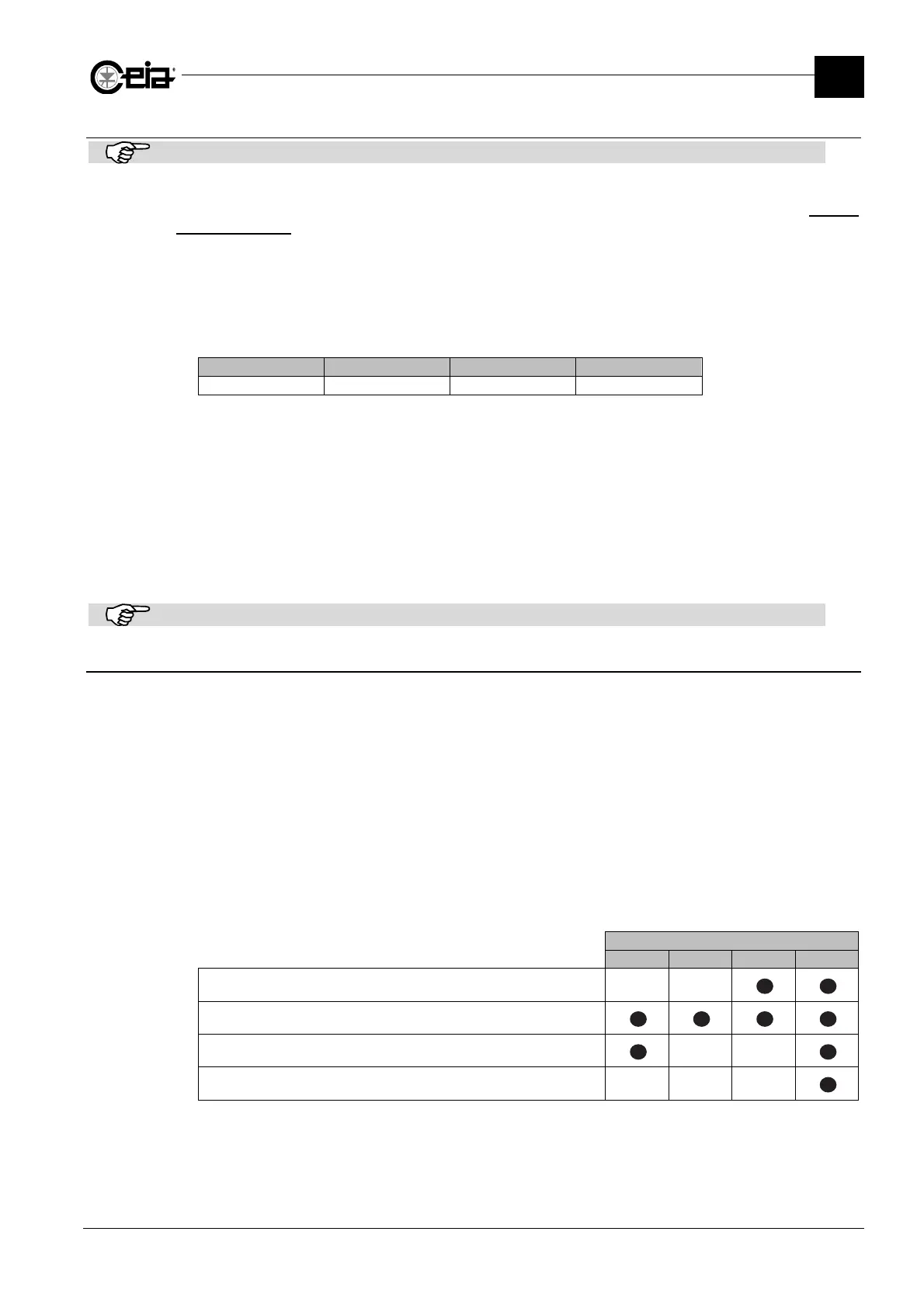

Steps with higher measured values

1/4 2/4 3/4 4/4

Electrical noise due to the transport (i.e. inverter and motor connection)

Generic electrical noise (due to any machine other than the one activated

during the procedure)

Generic mechanical noise (i.e. due to fixed or moving parts in the probe

nearby).

Mechanical noise due to the transport (i.e. uninsulated cylinders, vibrations)

To increase the Metal Detector environmental compatibility, refer to the BL, BS, BM, ADS and CH

parameters in the Programming Manual. Refer also to the sections of this manual on Electrical

installation and Mechanical installation.

Loading...

Loading...