Maintenance 5. Actuator Units

N6 Rev.2 283

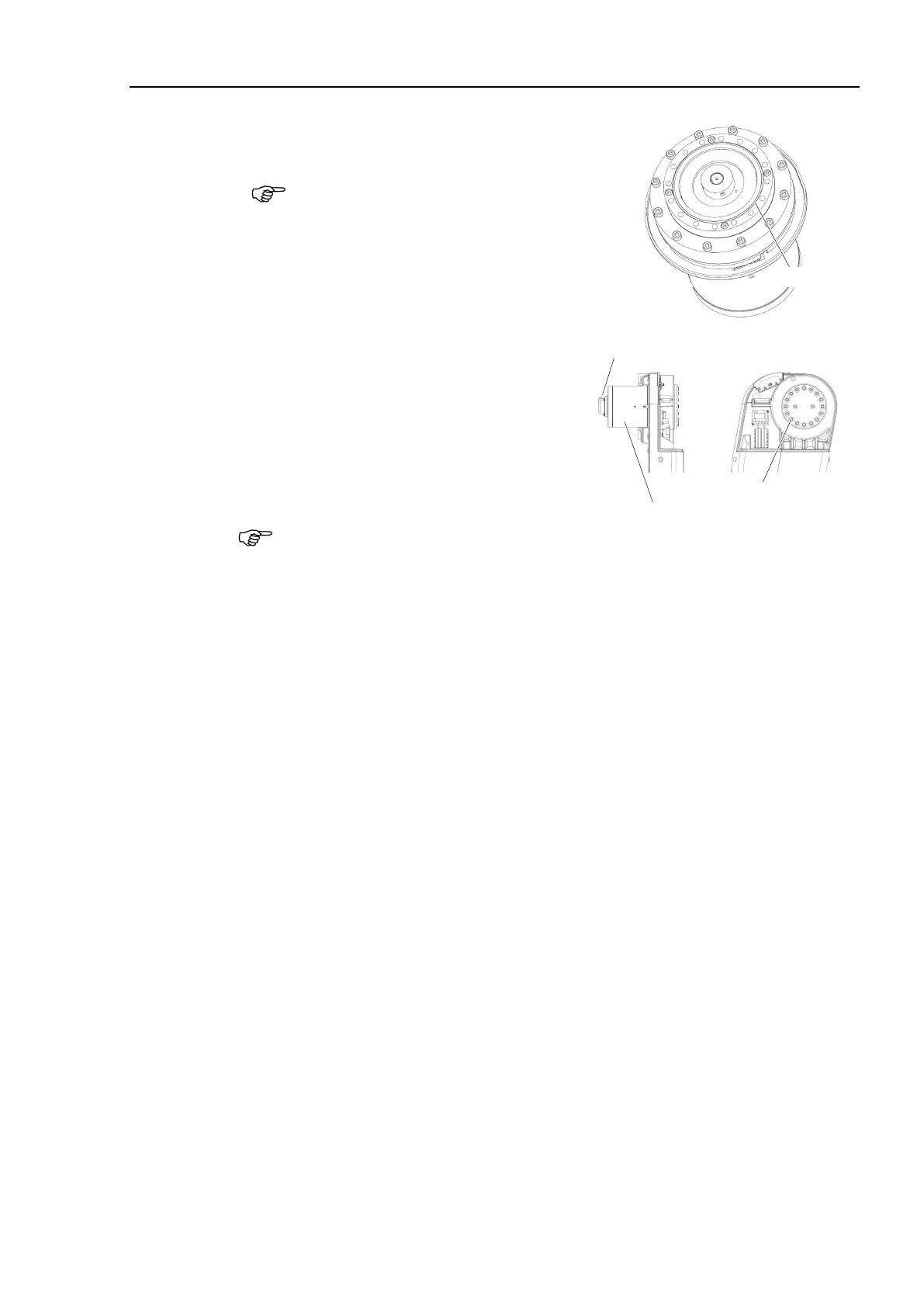

-A1000**

the attached O-ring on the Joint #2

Apply a thin coat of grease to the O

-ring.

Grease: SK-1A

Install the Joint #2 actuator unit to the Arm

#1.

Hexagon socket head cap bolts:

16-M5×35 (with plain washer)

Tightening torque: 10 ± 0.5 N·m

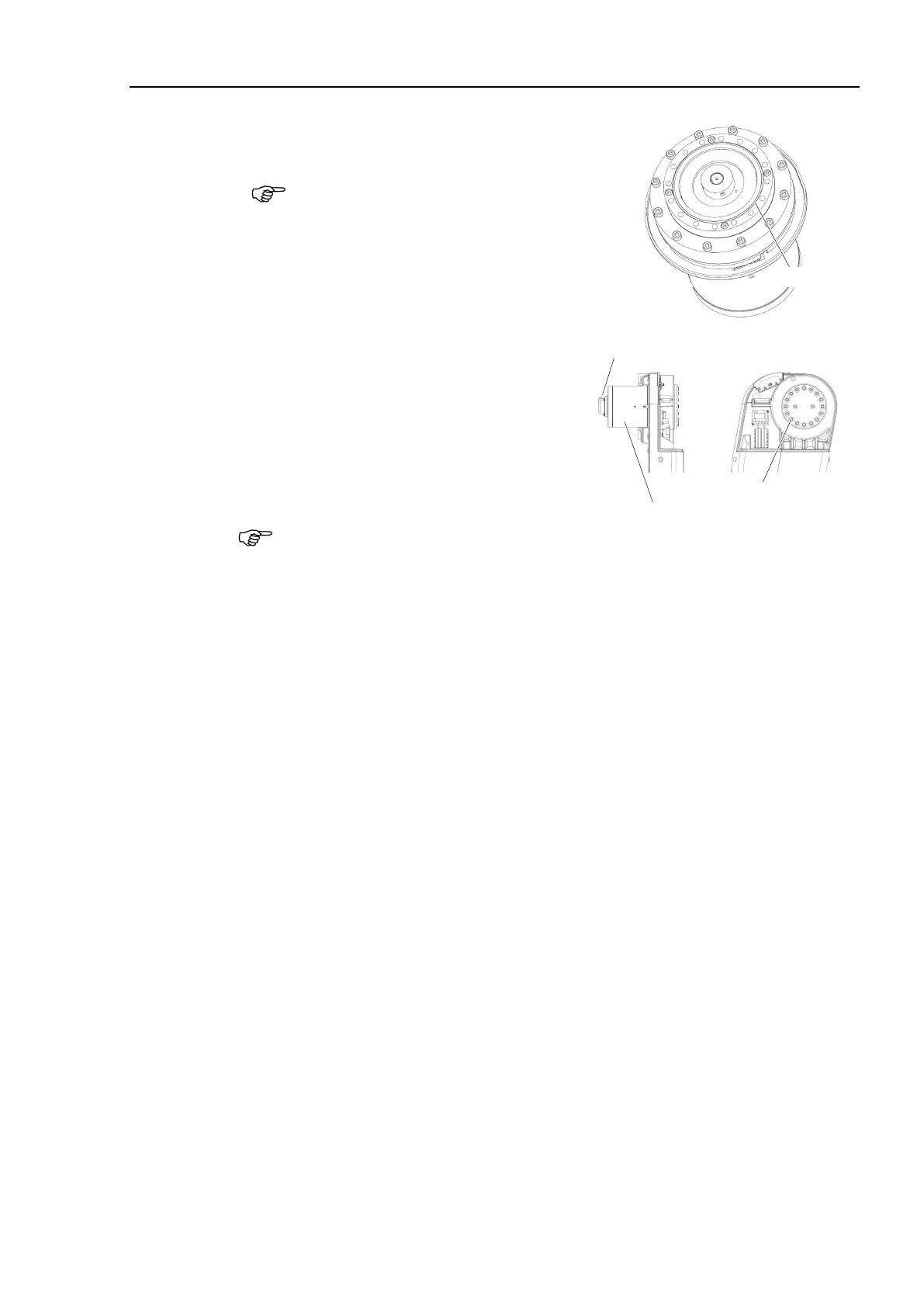

Refer to the figure and install it so that the

cable exit of the actuator unit will be the

opposite side of the base.

16-M5×35(with plain washer)

Cable exit

of the actuator unit

least 2 people to perform the operation since the parts being heavy.

Do not apply excessive shock to the parts.

-ring properly.

Install the robot arm and the cable unit.

For details, refer to the Removal steps (14) through (52) in Maintenance 4.1 Cable

Unit (N6-A1000*): Cable direction Standard (backward).

Install the following covers:

Arm #4 side cover (2 covers), Joint #4 inside cover, Joint #4 outside cover

Joint #4 side cover (2 covers), Arm #3 cover, Arm #3 inside cover

Arm #2 cover (2 covers), Joint #2 cover, Joint #2 outside cover

For details, refer to Maintenance 3. Covers.

.

For details, refer to Maintenance 8. Calibration.

Loading...

Loading...