Maintenance 2. General Maintenance

N6 Rev.2 95

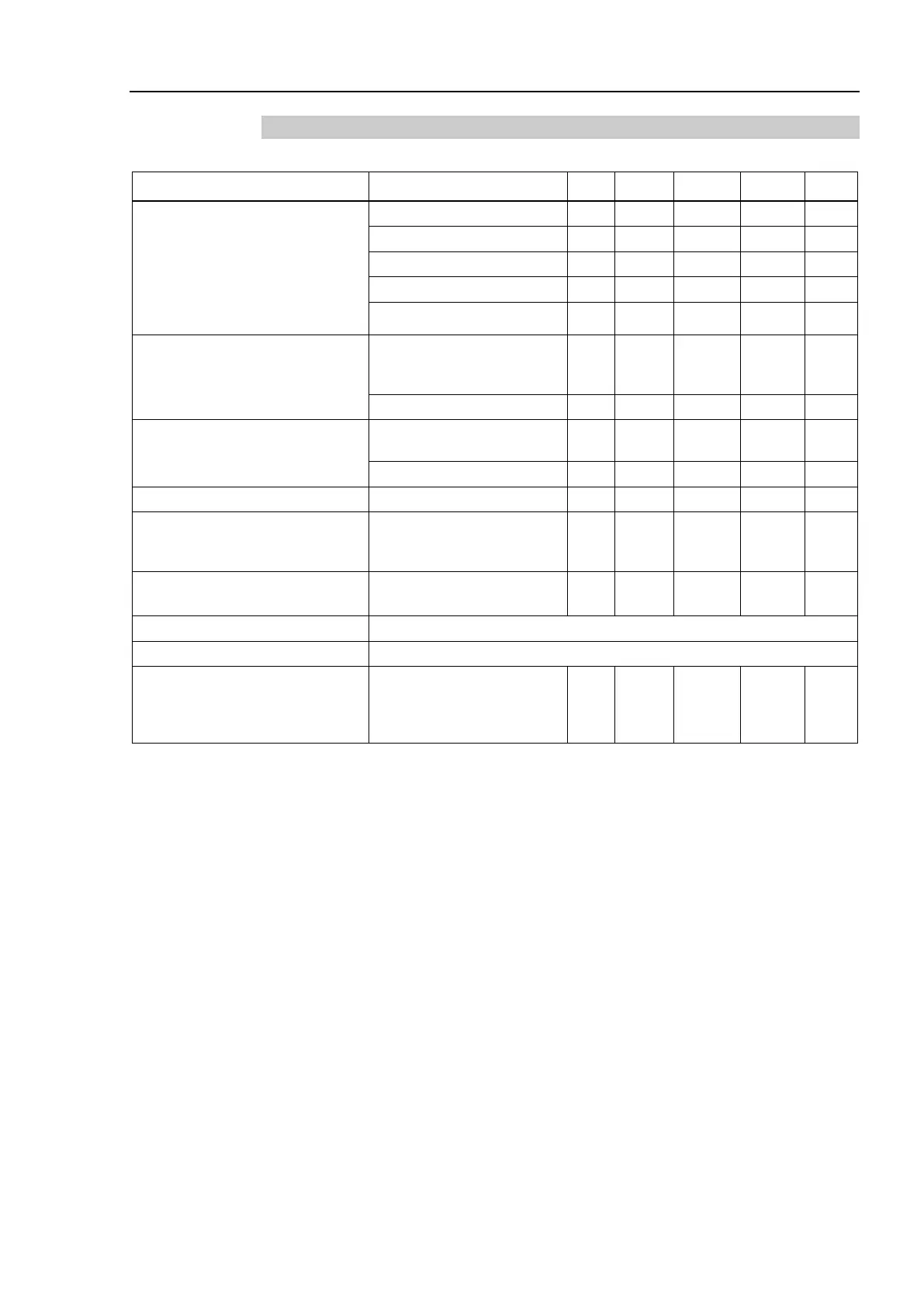

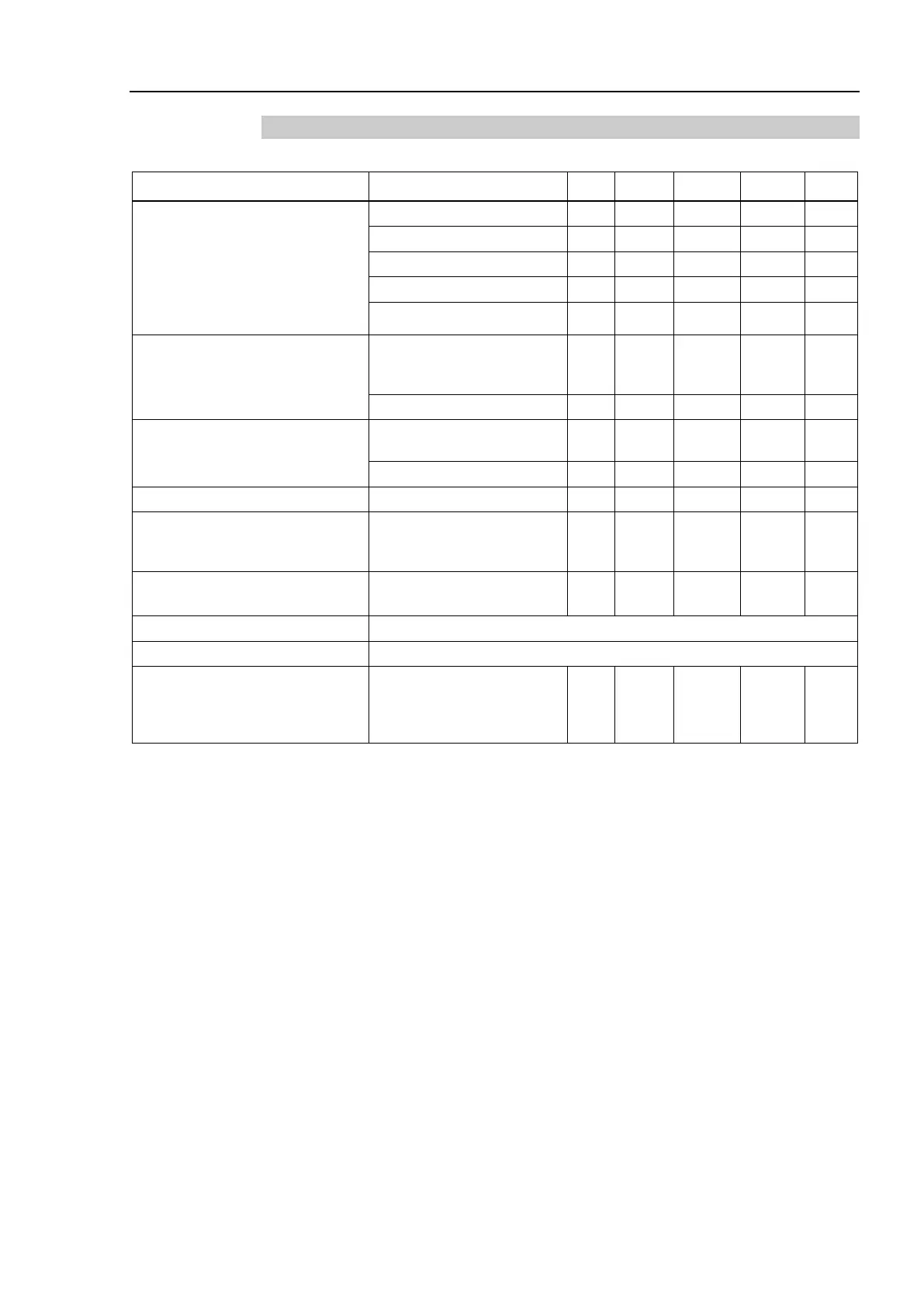

2.1.2 Inspection Point

Inspection While the Power is OFF (Manipulator is not operating)

Inspection Point Inspection Place Daily Monthly

Quarterly

Biannual Annual

Check looseness or backlash of

bolts/screws.

Tighten them if necessary.

(For the tightening torque, refer to

Maintenance: 2.4 Tightening

Hexagon Socket Head Cap Bolts.)

End effector mounting bolts

Manipulator mounting bolts

Each arm locking bolts

Bolts/screws around shaft

Bolts/screws securing motors,

reduction gear units, etc.

√

Check looseness of connectors.

If the connectors are loosen, push it

securely or tighten.

External connectors on

Manipulator (on the connector

plates etc.)

√ √ √ √ √

Manipulator cable unit

Visually check for external defects.

Clean up if necessary.

External appearance of

Manipulator

√ √ √ √ √

External cables

Check the leak of grease for cables. Joint #1 to Joint #4

Check for bends or improper

location. Repair or place it properly

if necessary.

Safeguard etc.

√ √ √ √ √

Check tension of timing belts.

Tighten it if necessary.

Inside of Arms #4

√ √

Grease conditions

Refer to Maintenance: 2.3 Greasing.

Battery

Refer to Maintenance: 6. Battery.

Check either the external short

connector or the brake release unit

connector is connected.

The external short connector

on the back side of the

Manipulator, or the brake

release unit connector.

√ √ √ √ √

Loading...

Loading...