Maintenance 5. Actuator Units

N6 Rev.2 307

5.5.3 Replacing the Joint #5 Electromagnetic Brake

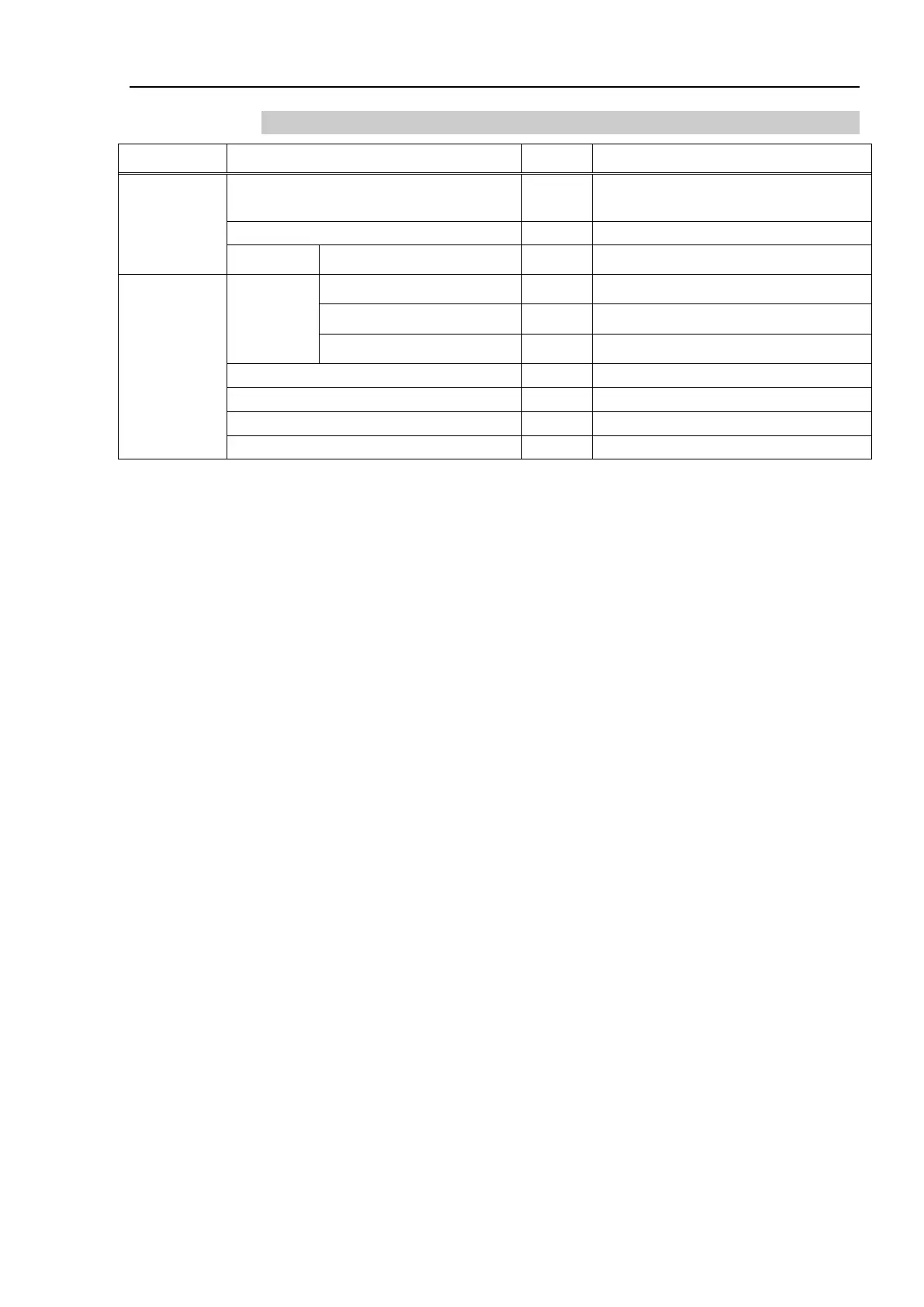

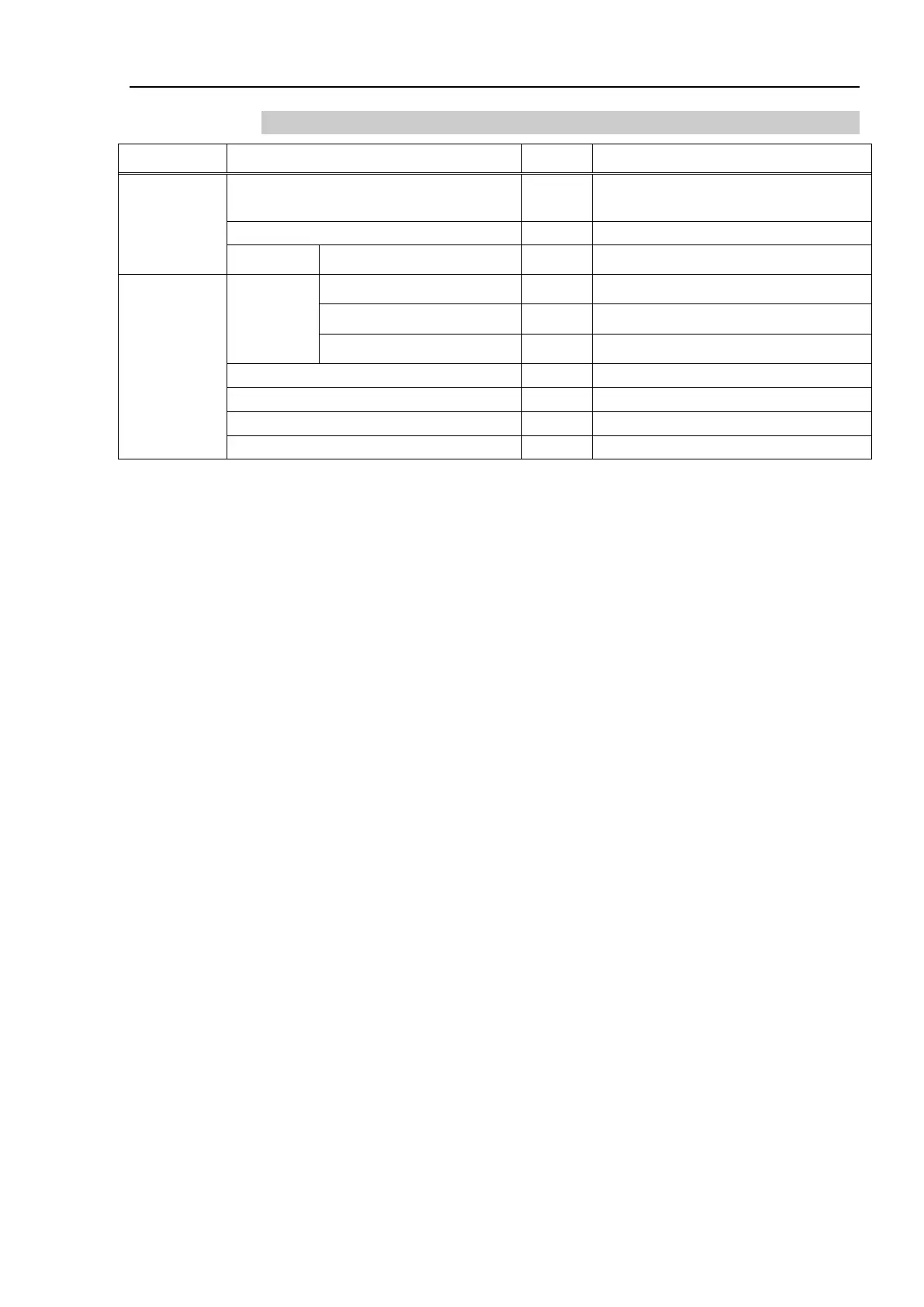

Name Qty Code, Note

Maintenance

Parts

Electromagnetic Brake 1

1670649

(Common to Joint #5 and #6)

Cable tie AB200 - 1684328 1 bag (100 ties: white)

Tools

Hexagonal

wrench

width across flats: 2 mm 1 For M4 hexagon socket set screw

width across flats: 2.5 mm 1 For M3 hexagon socket head cap bolts

width across flats: 3 mm 1 For M4 hexagon socket head cap bolts

Cross-point screwdriver (#2)

For cross recessed head screws

For tightening torque control

For positioning of drive boss

* The belt tensile jig is an assembly jig. Use this jig when adjusting belt tension.

The brake is mounted on each joint to prevent the arm from lowering due to its own

weight while the controller power is OFF or the motor is OFF status. The brake does not

work during replacement. Be careful when performing maintenance work.

Removal

(1)

Remove the Joint #5 electromagnetic brake.

For details, refer to Removal steps (1) through (10) in Maintenance

Replacing the Joint #5 Motor Unit.

Installation

(1)

Install the Joint #5 electromagnetic brake.

For details, refer to Installation steps (2) through (10) in Maintenance

Replacing the Joint #5 Motor Unit.

Loading...

Loading...