Maintenance 8. Calibration

N6 Rev.2 353

Also, pay attention to the following points at the encoder initialization.

CAUTION

■

s #1 to Joint #4 have no mechanical stops. If the encoder initialization

is performed with improper posture, the Manipulator moves outside the operation

range.

If the Manipulator was moved outside the operation range, the internal

wiring may be damaged by being twisted or pinched and it may result in

Manipulator malfunction.

1 to #4 rotates 360 degrees, the Manipulator will be the same posture.

+180 degree and −180 degree is the same.

When you are not sure the current joint angle, check the internal wiring and tubing

(cables).

You can check the cable conditions by removing

the each cover.

Joint #1 : Base cover

Joint #2 : Joint #2 cover (N6-A1000**), Arm #1 inside cover (N6-A850**R)

Joint #3 : Arm #3 inside cover

Joint #4 : Joint #4 inside cover, Joint #4 outside cover

For procedures of the cover removal, refer to Maintenance 3. Covers.

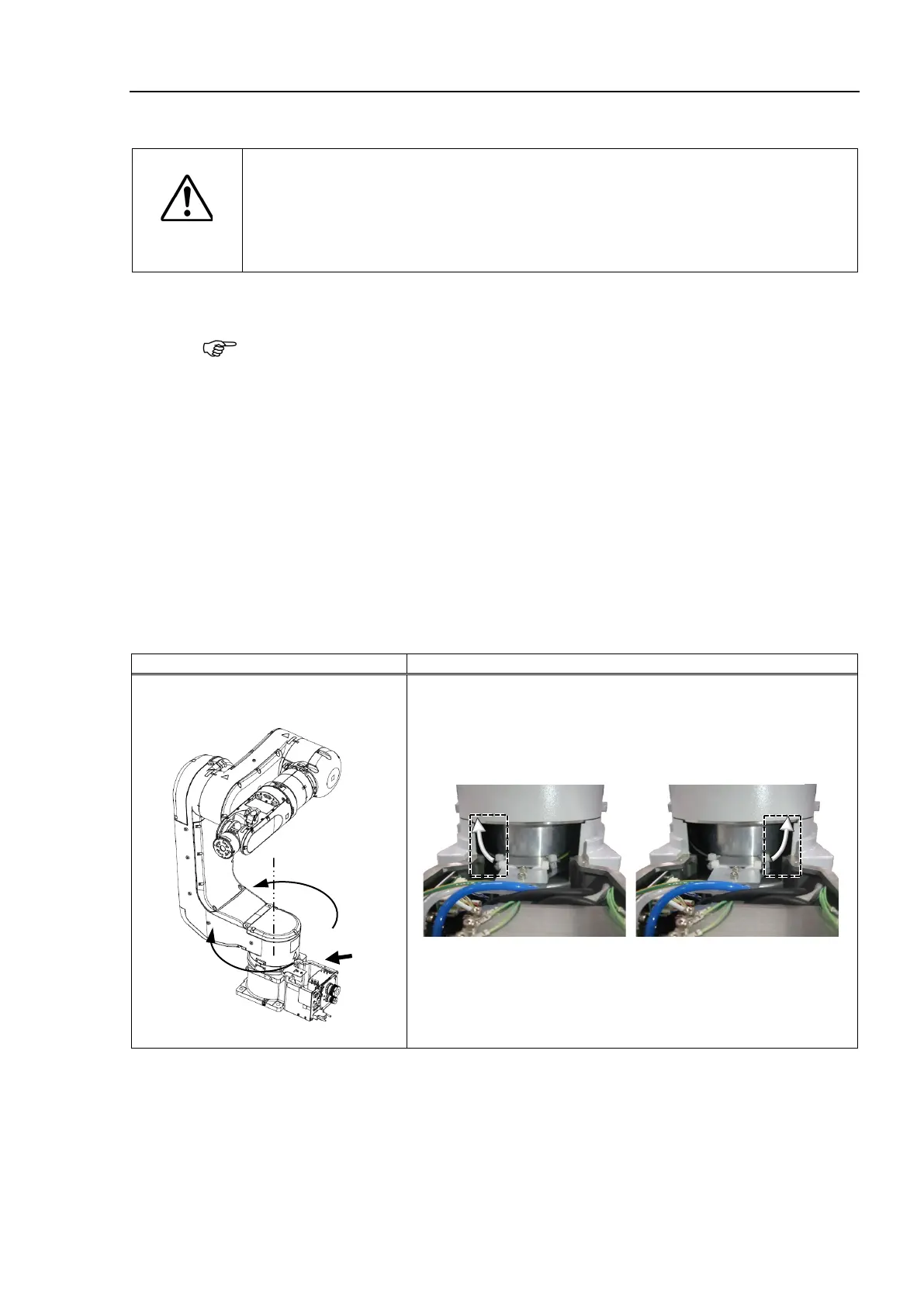

are examples of the cable conditions at ±180 degree posture.

White arrow is an image of the cable.)

N6-A1000**

Joint #1

Cable direction: Arm #1 side

Loading...

Loading...