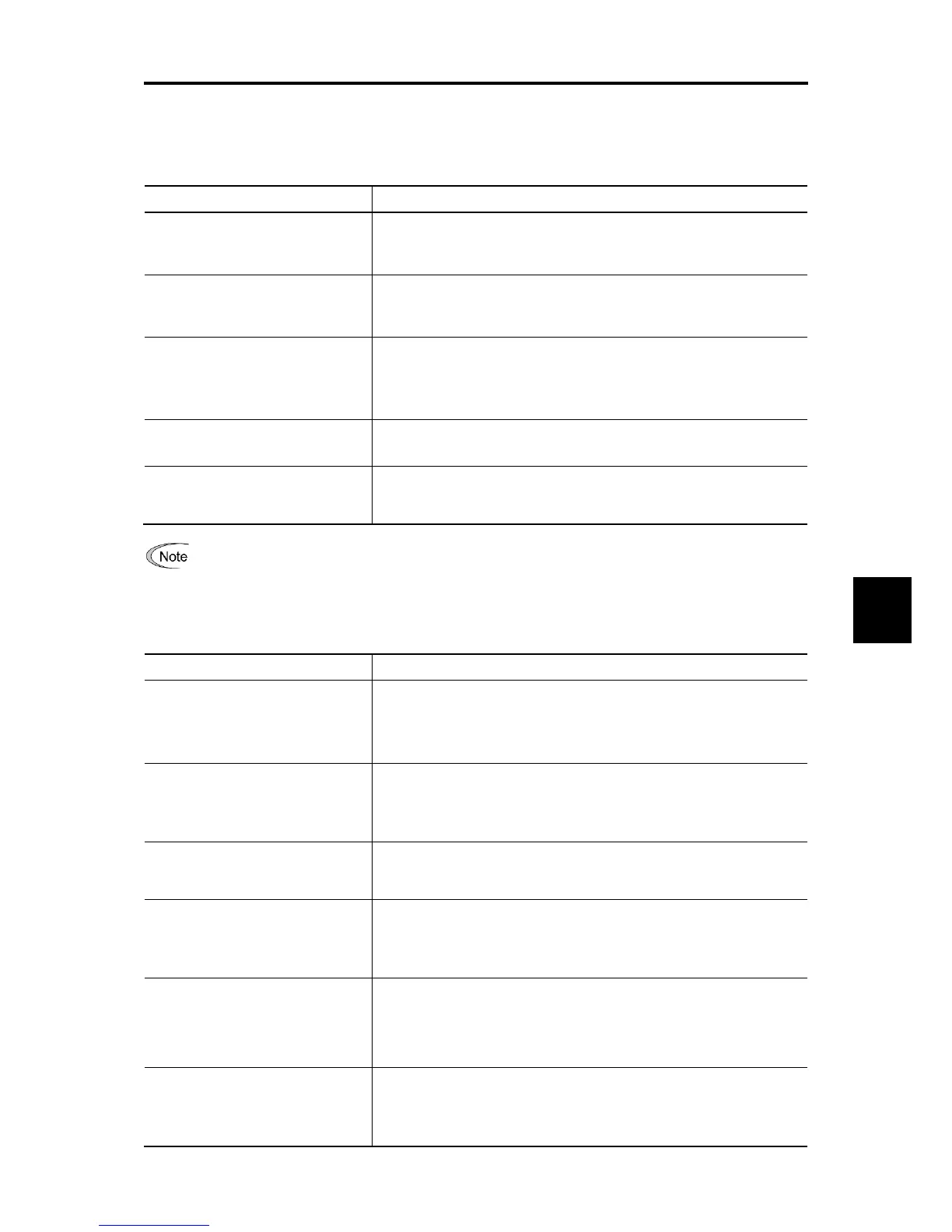

Input phase loss

Phenomena Input phase loss occurred, or interphase voltage unbalance rate was large.

If the auxiliary power (R0, T0) is taken from the breaker primary side (power supply side), a “

lin

”

alarm may occur even if there has been no phase loss.

Possible Causes Check and Measures

(1) Breaks in wiring to the main

power input terminals.

Measure the input voltage.

Repair or replace the main circuit power input wires or input devices

(MCCB, MC, etc.).

(2) The screws on the main power

input terminals are loosely

tightened.

Check if the screws on the main power input terminals have become

loose.

Tighten the terminal screws to the recommended torque.

(3) Interphase voltage unbalance

among three phases was too

large.

Measure the input voltage.

Connect an AC reactor (ACR) to lower the voltage unbalance

between input phases.

Increase the inverter capacity.

(4) Overload cyclically occurred. Measure the ripple wave of the DC intermediate circuit voltage.

If the ripple is large, increase the inverter capacity.

(5) Single-phase voltage was input

to the three-phase input

inverter.

Check the inverter type.

Apply three-phase power.

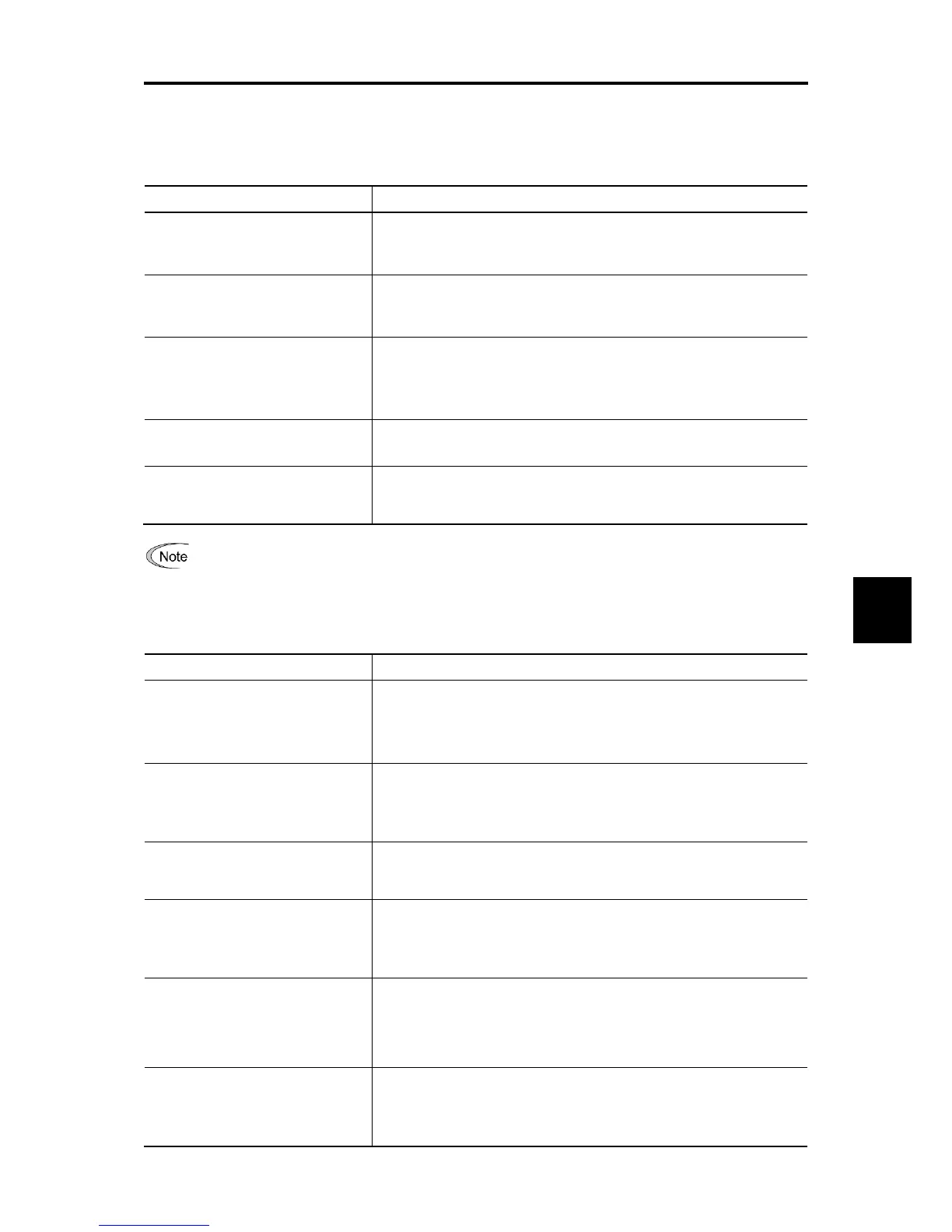

Undervoltage

Phenomena DC intermediate circuit voltage has dropped below the undervoltage detection level.

Possible Causes Check and Measures

(1) A momentary power failure

occurred.

[Subcode:1]

[Subcode:

3]

Release the alarm.

If you want to restart running the motor without treating this

condition as an alarm, set F14 to “3,” “4,” or “5,” depending on the

load type.

(2) The power to the inverter was

switched back to ON too soon

(when F14 = 1).

[Subcode:2]

Check if the power to the inverter was switched back to ON while the

control power was still alive. Check whether the LEDs on the keypad are

lit.

Turn the power ON again after all LEDs on the keypad go off.

(3) The power supply voltage did

not reach the inverter's type

correct range.

Measure the input voltage.

Increase the voltage to within the specified range.

(4) Peripheral equipment for the

power circuit malfunctioned, or

the connection was incorrect.

Measure the input voltage to find which peripheral equipment

malfunctioned or which connection is incorrect.

Replace any faulty peripheral equipment, or correct any incorrect

connections.

(5) Any other loads connected to

the same power supply has

required a large starting current,

causing a temporary voltage

drop.

Measure the input voltage and check the voltage fluctuation.

Reconsider the power supply system configuration.

(6) Inverter's inrush current caused

the power voltage drop because

the power supply transformer

capacity was insufficient.

Check if the alarm occurs when a molded case circuit breaker (MCCB),

earth leakage circuit breaker (ELCB) (with overcurrent protection) or

magnetic contactor (MC) is turned ON.

Reconsider the capacity of the power supply transformer.

Loading...

Loading...