contact with the main circuit live section, the insulation cover may be damaged. High voltage of the main circuit

may be applied on the control signal lines, so exercise caution such that the main circuit live sections do not

contact the control signal lines.

Risk of accidents and risk of electric shock exist.

Exercise caution to prevent malfunction of peripheral sensors and instruments.

Risk of accidents exists.

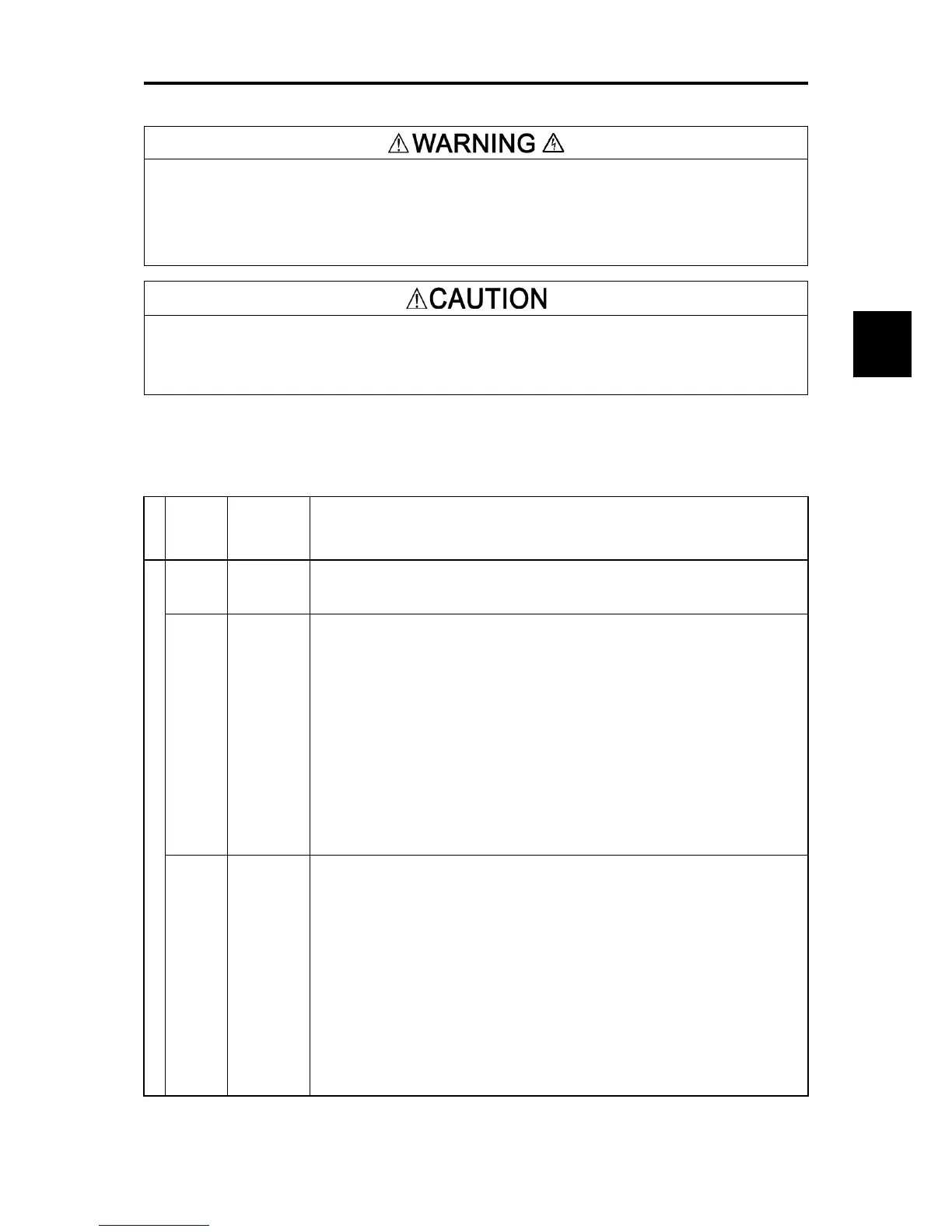

Table 2.2-30 shows the functional explanations for the control circuit terminals. The connection method of the

control circuit terminals differs depending on the functional code setting matching the purpose of inverter operation.

Properly wire such that the impact of noise generated by the main circuit wiring is reduced.

Table 2.2-30 Functional Description of Control Circuit Terminals

Classification

Terminal

symbol

Terminal name

Functional description

Analog input

[13] Power supply

for the

potentiometer

The terminal is used for the power supply (DC+10 V 10 mA Max) for the external frequency

command potentiometer (variable resistor: 1 to 5 kΩ).

Connect variable resistors larger than 1/2 W.

[12] Analog setup

voltage input

(1) Frequency is set up according to the external analog voltage input command value.

Normal operation

• DC0 to +10 V/0 to 100(%) (DC0 to +5 V/0 to 100%)

• DC0 to ±10 V/0 to ±100(%) (DC0 to ±5 V/0 to ±100%)

Reverse operation

• DC+10 to 0V/0 to 100(%) (DC+5 to 0 V/0 to 100%)

• DC±10 to 0V/0 to ±100(%) (DC±5 to 0V/0 to ±100%)

(2) The terminal can be assigned to PID command, feedback signal of PID control, auxiliary

frequency setup, ratio setup, torque limit setup, and analog input monitor aside from the

frequency setup by analog input.

(3) Hardware specification

* Input impedance: 22 (kΩ)

* Up to DC±15 V can be input. However, input exceeding DC±10 V will be recognized as

DC±10 V.

[C1] Analog setup

current input

(C1 function)

(1) Frequency is set up according to the external analog current input command value.

Normal operation

• DC4 to 20 mA/0 to 100(%)/-100% to 0 to 100%

• DC0 to 20 mA/0 to 100(%)/-100% to 0 to 100%

Reverse operation

• DC20 to 4 mA/0 to 100(%)/-100% to 0 to 100%

• DC20 to 0 mA/0 to 100(%)/-100% to 0 to 100%

(2) The terminal can be assigned to PID command, feedback signal of PID control, auxiliary

frequency setup, ratio setup, torque limit setup, and analog input monitor aside from the

frequency setup by analog input.

(3) Hardware specification

* Input impedance: 250 (Ω)

* Up to DC 30 mA can be input. However, input exceeding DC 20 mA will be recognized as

DC 20 mA.

Loading...

Loading...