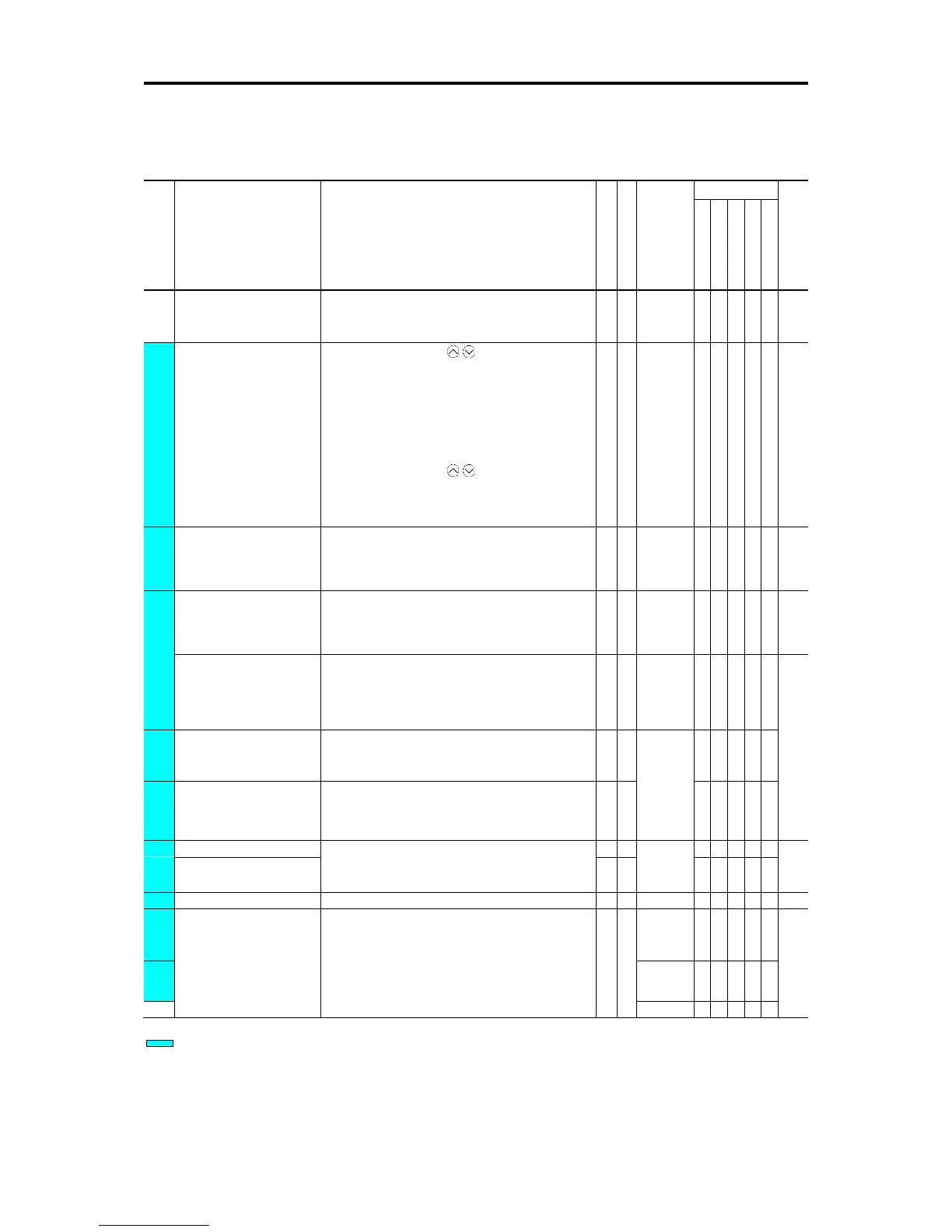

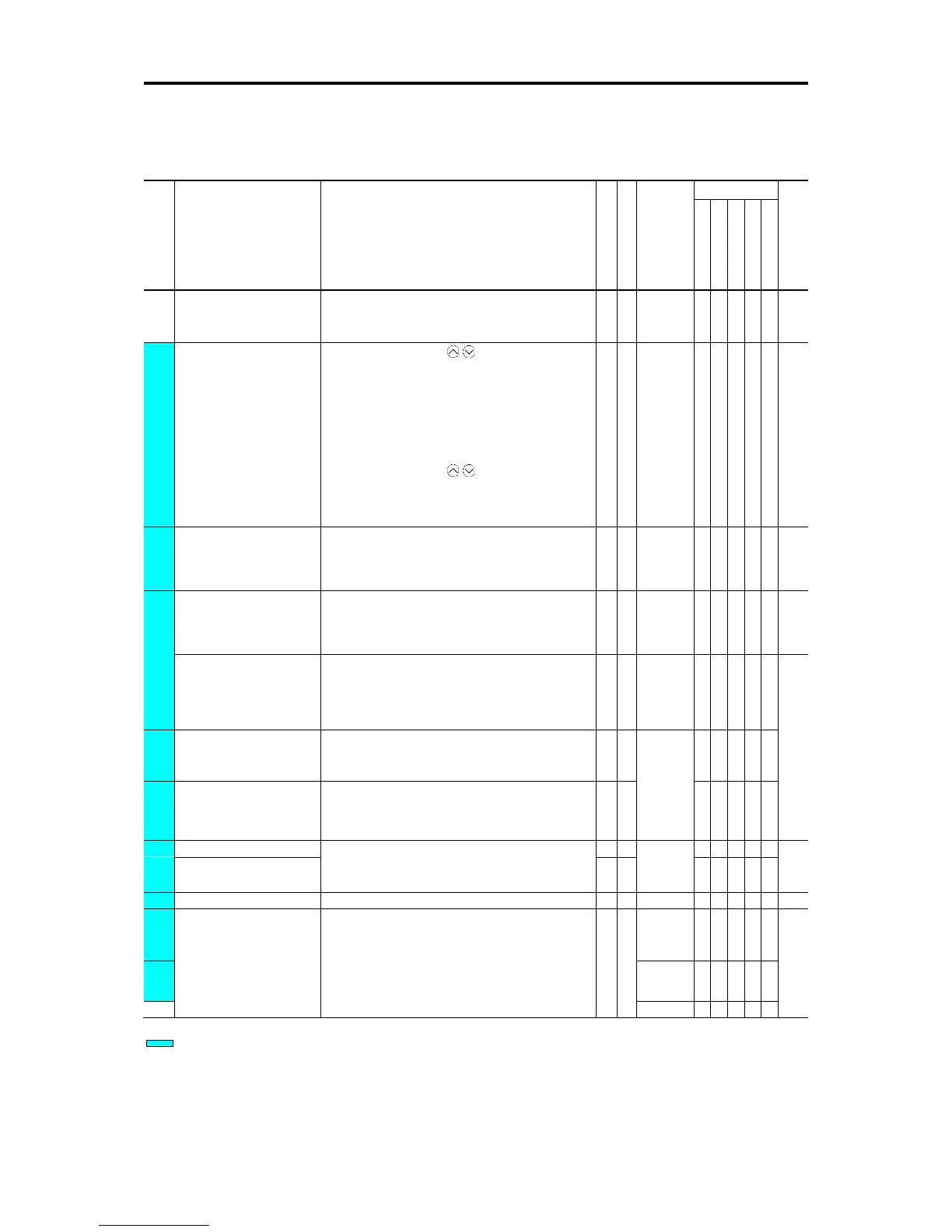

5.2 Function Codes Table

5-4

5.2.2 Function codes table

The table of function codes to be used in FRENIC-Ace is shown below.

■ F codes: Fundamental Functions (Basic function)

Code

Name Data setting range

Change when running

Data copying

Factory

Default

0: No data protection, no digital setting protection

1: With data protection, no digital setting protection

2: No data protection, with digital setting protection

3: With data protection, with digital setting protection

0: Keypad key operation ( / key)

1: Analog voltage input (Terminal [12])

(from 0 to ±10 VDC)

2: Analog current input (Terminal [C1] (C1 function))

(4 to 20mA DC, 0 to 20mA DC)

3: Analog voltage input (Terminal [12]) + Analog current

input (Terminal [C1] (C1 function))

5: Analog voltage input (Terminal [C1] (V2 function))

(0 to 10 VDC)

7: UP/DOWN control

8: Keypad key operation ( / key)

(With balanceless bumpless)

10: Pattern operation

11: Digital input/output interface card (option) *5

(rotation direction input: terminal block)

1: External signal (digital input)

2: Keypad operation (forward rotation)

3: Keypad operation (Reverse rotation)

Maximum output frequency 1

J:50.0

AUK:60.0

400V class

(output voltage proportional to power voltage)

80 to 240 V : AVR operation (200V class)

160 to 500V : AVR operation (400V class)

J:200

AK:220

U:230

400V class

80 to 240V : AVR operation (200V class)

160 to 500V : AVR operation (400V class)

* 0.00 is for acceleration and deceleration time cancel

(when performing soft-start and stop externally)

0.0 to 20.0% (% value against base frequency voltage 1)

Electronic thermal overload

protection for motor 1

(Select motor characteristics)

1: Enable (For a general-purpose motor with self-cooling

fan)

2: Enable (For an inverter-driven motor (FV) with

separately powered cooling fan)

(Overload detection level)

0.00 (disable), current value of 1 to 135% of inverter rated

(Inverter rated current dependent on F80)

Factory default

A (For Asia), C (for China), E (for Europe), U (For USA), J (for Japan), K (for Korea)

indicates quick setup target function code.

*2: Factory defaults are depended on motor capacity. Refer to “5.2.3 Factory default value per applicable electric motor capacitance”.

*3: The motor rated current is automatically set. Refer to “5.2.4 Motor constant”.

*4: 5.0min for inverters of nominal applied motor 22kW or below; 10.0min for those of 30kW or above.

*5: Available at ROM version 0300 or later.

*10: 6.00s for inverters of nominal applied motor 22kW or below; 20.0s for those of 30kW or above.

Loading...

Loading...