(3) Deceleration time (For detailed calculation, refer to Section 10.3.2 [ 4 ] .)

To calculate the deceleration time, check the motor deceleration torque characteristics for the whole range of

speed in the same way as for the acceleration time.

1) Calculate the moment of inertia for the load and motor

Same as for the acceleration time.

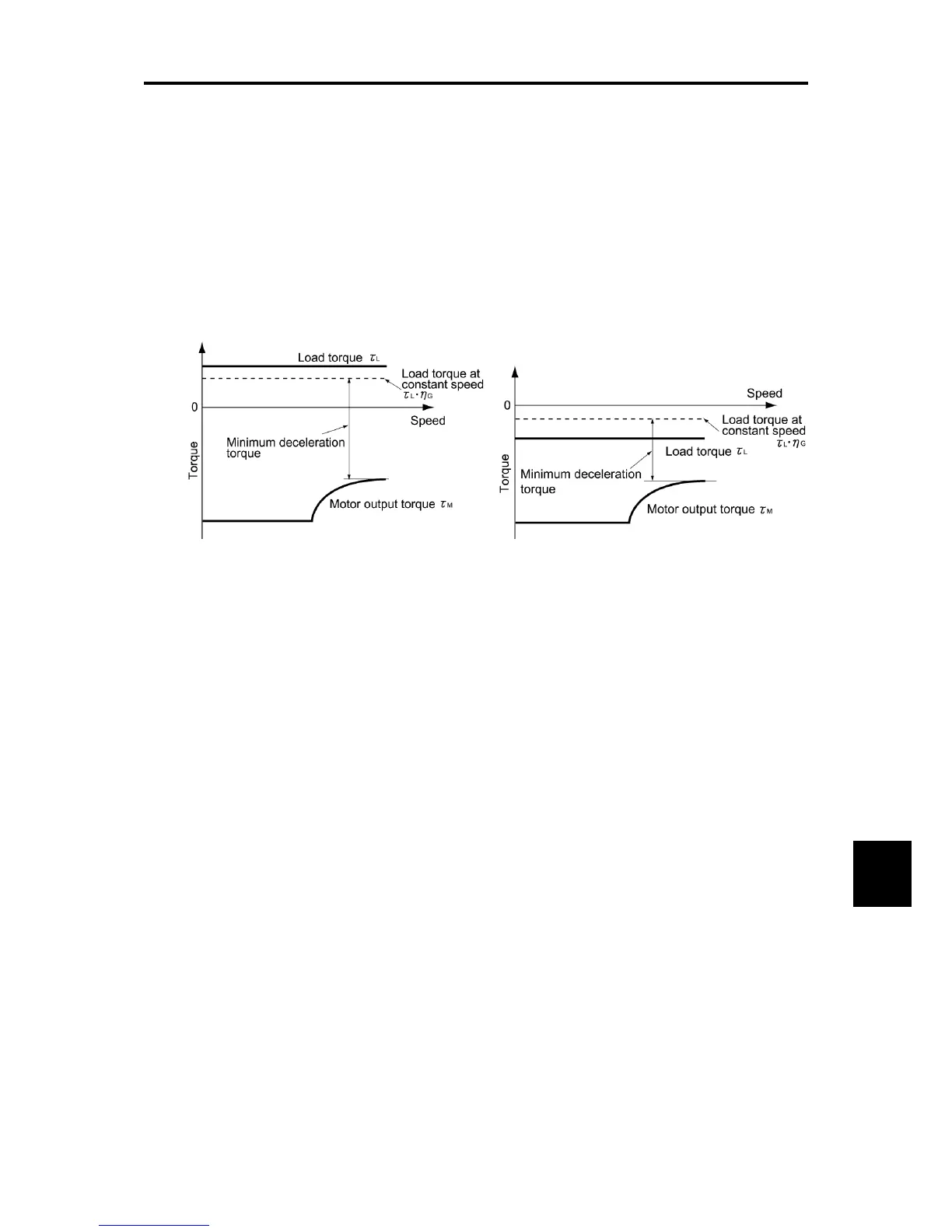

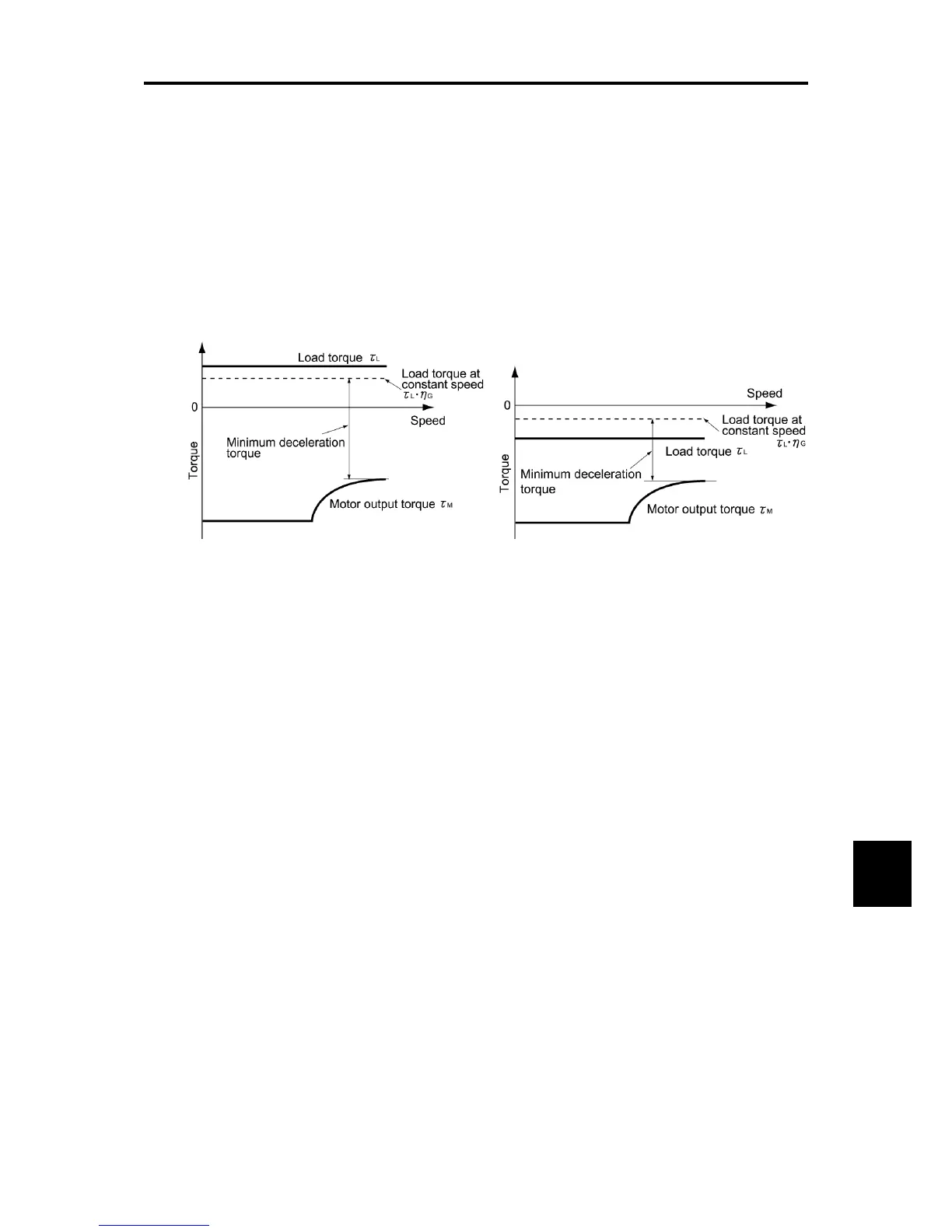

2) Calculate the minimum deceleration torque (See Figure 10.2-3 and Figure 10.2-4)

Same as for the deceleration time.

3) Calculate the deceleration time

Assign the value calculated above to the equation (Equation 10.3-16) to calculate the deceleration time in the

same way as for the acceleration time. If the calculated deceleration time is longer than the requested time,

select the inverter and motor having one class larger capacity and calculate it again.

Figure 10.2-3 Example Study of Minimum

Deceleration Torque (1)

Figure 10.2-4 Example Study of Minimum

Deceleration Torque (2)

(4) Braking resistor rating (For detailed calculation, refer to Section 10.3.3 .)

Braking resistor rating is classified into two types according to the braking periodic duty cycle.

1) When the periodic duty cycle is 100 seconds or less:

Calculate the average loss to determine rated values.

2) When the periodic duty cycle exceeds 100 seconds:

The allowable braking energy depends on the maximum regenerative braking capacity. The allowable values

are listed in Chapter 11 “11.8 Braking Resistors (DBRs) and Braking Units.”

(5) Motor RMS current (For detailed calculation, refer to Section 10.3.4 .)

In metal processing machines and materials handling machines requiring positioning control, highly frequent

running for a short time is repeated. In this case, calculate the maximum equivalent RMS current value (effective

value of current) not to exceed the allowable value (rated current) for the motor.

Loading...

Loading...