190

Program description - Helicopter mixer

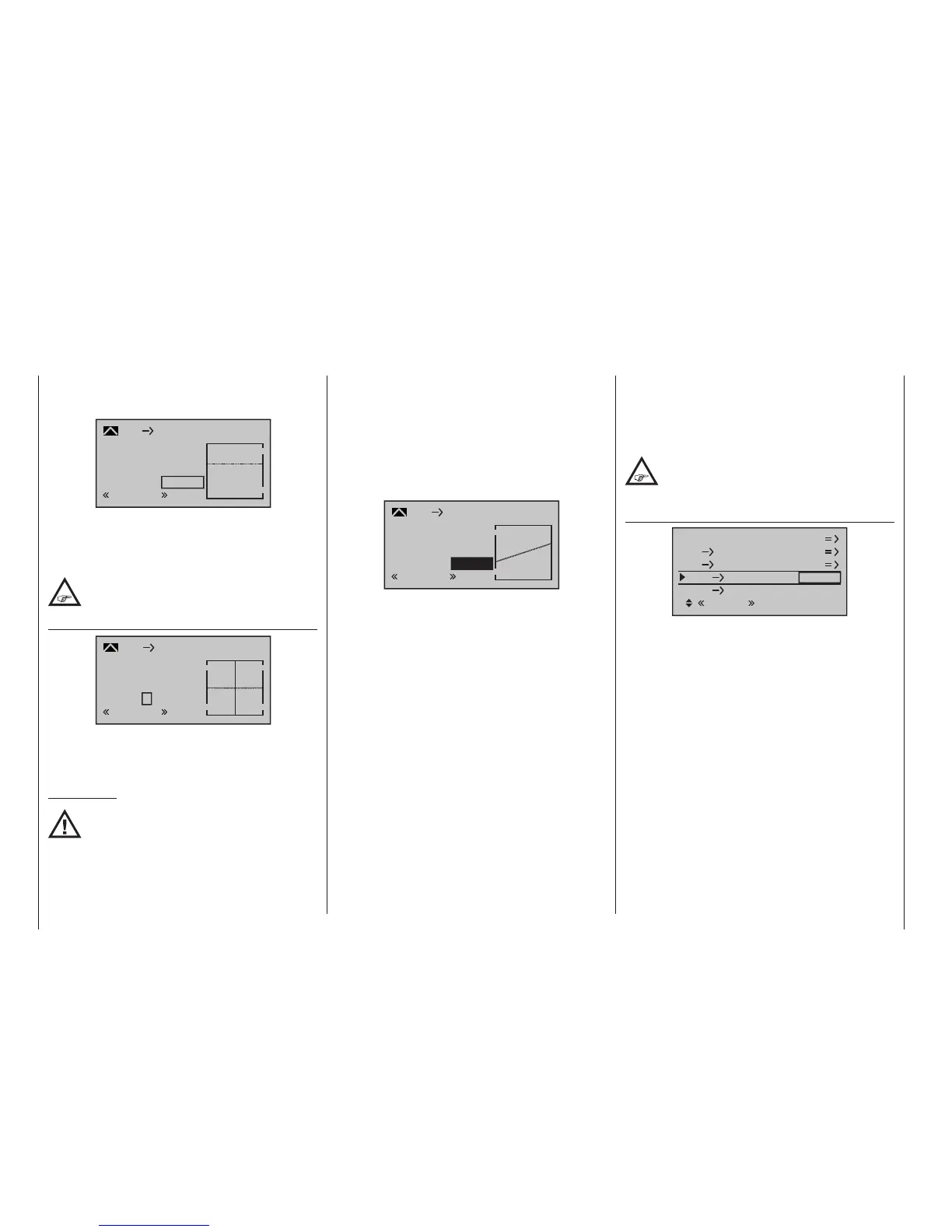

Following this, the reference points “L” (input = 0 %)

and “H” (input = +100 %) are then each set to the same

value, for example:

0%

+65%

+65%

C1 Thro

normal

L

Input

Output

Point

Curve

off

The value to be set depends both on the speed con-

troller used and on the target motor speed that is

desired, and can, of course, be varied according to the

flight phase.

For auto-rotation ight, an automatic

switch-over is made from this mixer to a

congurable default value; see page 198.

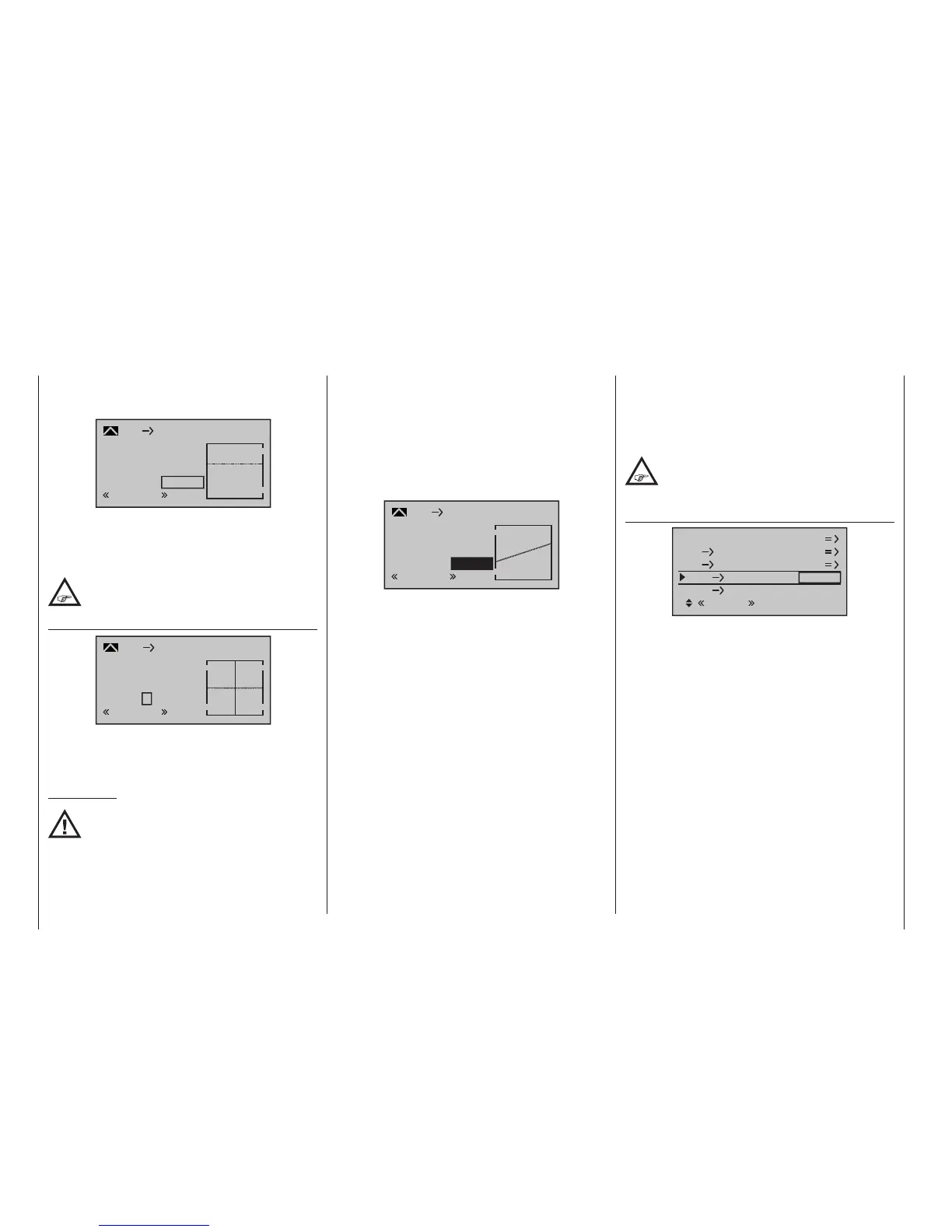

C1 Tail (Static torque compensation)

0%

0%

0%

Tail

C1

normal

?

Input

Output

Point

Curve

off

The default approach here is to preset a torque com-

pensation curve with a linear mixer ratio of a uniform

0 %, as is required for a gyro sensor working in “head-

ing lock mode” – see the screen image above.

ATTENTION:

In this context, ensure that you comply

with the instructions on adjusting your

gyro: if not, you risk making adjustments

that render your helicopter impossible to y.

If, on the other hand, you use your gyro sensor in

the “normal” operating mode, or if it only has what is

termed “normal mode”, then configure the mixer as

follows:

Note that the output signal of the “Channel 1 curve”

option also functions as an input signal for the tail rotor

curve programmed here: In the graph, the vertical line

is synchronized with the throttle/collective pitch stick

and follows the current Channel 1 curve characteristic

from the »Channel 1 curve« menu.

In the auto-rotation ight phase this mixer

is automatically switched off, see page

198.

Tail Throttle

Pitch

0%

0%

SEL

normal

C1

C1

Throttle

Tail

Tail

Roll

Throttle

Throttle

While the tail rotor normally compensates for the effect

of main rotor torque on the fuselage, it is also used to

control the helicopter around the vertical axis. Increas-

ing tail rotor thrust requires a corresponding adjustment

to motor power, however, to avoid a fall-off in system

rotational speed.

This mixer sets the extent to which the throttle follows

the tail rotor. The throttle will follow on one side only, to

the side on which the tail rotor thrust is increased. The

setting range is therefore 0 to +100 %. The direction

depends on the main rotor’s direction of rotation (left or

right), and this must first be set correctly on the »Heli-

copter type« menu. For left-hand rotation systems, the

throttle follows the tail rotor when the tail rotor stick is

moved to the left, and vice versa for right-hand rotation

systems.

A simultaneous tap on the or keys of the right

four-way button (CLEAR) will reset a changed value in

an active (inverse video) field back to 0 %.

As with the configuration of the collective pitch curve

(see page 185), the control curve of the tail rotor can

also be defined by up to 6 points. If required, therefore,

you can modify the mixer at any time and preset both

symmetrical and asymmetric mixer ratios both above

and below the hover point. Before you do, however,

ensure you have entered the correct direction of ro-

tation for the main rotor on the »Helicopter type«

menu(see page 103).

+100%

+30%

Tail

C1

normal

H

+30%

Input

Output

Point

Curve

off

Starting with values of -30 % for point “L” and +30 %

for point “H”, the mixer is to be configured in such a

way that the helicopter, even during prolonged verti-

cally ascending or descending flights, does not deviate

from the yaw axis as a result of the main rotor’s altered

torque while hovering. For hovered flight, trim should

only be affected by way of the (digital) tail rotor trim

lever.

For a reliable torque compensation setting, it is es-

sential that the collective pitch and throttle curves have

been set up correctly, i. e. that the rotor speed remains

constant over the collective pitch’s full adjustment

range.

This third curve mixer applies only to the control curve

of the tail rotor servo when the throttle/collective pitch

stick is moved, whereas the “Channel 1 curve”, see

page 137, acts on all servos that are affected by the

throttle/collective pitch stick.

Loading...

Loading...