240

Program description - Telemetry

TRIM (trim position)

In the “TRIM” line” you can carry out the fine adjust-

ment of the neutral position of a servo connected to

the control channel selected in the “OUTPUT CH” line

using the selection keys of the right four-way button

in 1 μs increments. The value in the “Centre” line can

be adjusted by the TRIM value set here in a range of

± 120 µs.

Factory setting: 0 μs.

LIMIT–/+ (side dependent travel limit –/+)

This option is provided for the adjustment of a side-de-

pendent limit (limiting) of the servo travel (rudder throw)

of the servo connected to the control channel selected

in the “OUTPUT CH” line.

The settings for both directions are separate but both

are in a range of 30 … 150 %.

Factory setting: 150 % each.

PERIOD (cycle time)

In this line you determine the time interval of the indi-

vidual channel impulse. This setting is adopted for all

control channels.

With the use of only digital servos, a cycle time of

10 ms can be set.

In mixed operation or with use of only analog servos,

20 ms should absolutely be set, because the latter can

otherwise be “over-strained” and react with “shaking”

or “quivering” as a result.

RX FAIL SAFE

RX FAIL SAFE V3.78

INPUT CH: 01

MODE : HOLD

F.S.POS. : 1500µsec

DELAY : 0.75sec

OUTPUT CH: 01

FAIL SAFE ALL: NO

POSITION : 1500µsec

The description of this menus necessitates a few words

of warning in advance:

“Do nothing” is the absolute worst thing to be

done in this regard. “HOLD” is prescribed in

the base setup model of the HoTT receiver.

In the event of a failure, in the best case scenario the

model ies straight ahead for an indenite amount of

time and then hopefully “lands” somewhere without

causing signicant damage! However, if something

like this happens in the wrong place at the wrong

time, the model may become uncontrollable and

“tear” across the ight eld completely out of control,

putting the pilot and spectators at risk.

Therefore, it would obviously be benecial to program

the the function “Motor off” at the very least, in order

to prevent such risks. If necessary, seek the advice of

an experienced pilot in order to nd a “logical” setting

for your model.

And then another brief notice regarding the three possi-

ble versions of the

mc-16 HoTT and mc-20 HoTT

transmitters for the setting of Fail Safe:

The easiest, and recommended, way to fail-safe set-

tings is the use of the »Fail Safe« menu, which can be

reached from the multifunction menu, see page 216.

Similarly, in order to achieve the same result somewhat

more laboriously, the “FAIL SAFE ALL” option de-

scribed on the following pages is also available.

In addition, there are the relatively elaborate methods

of the individual adjustment using the options “MODE”,

“F.S.Pos.” and “DELAY”. The description of these vari-

ants begins with the “MODE” option further below.

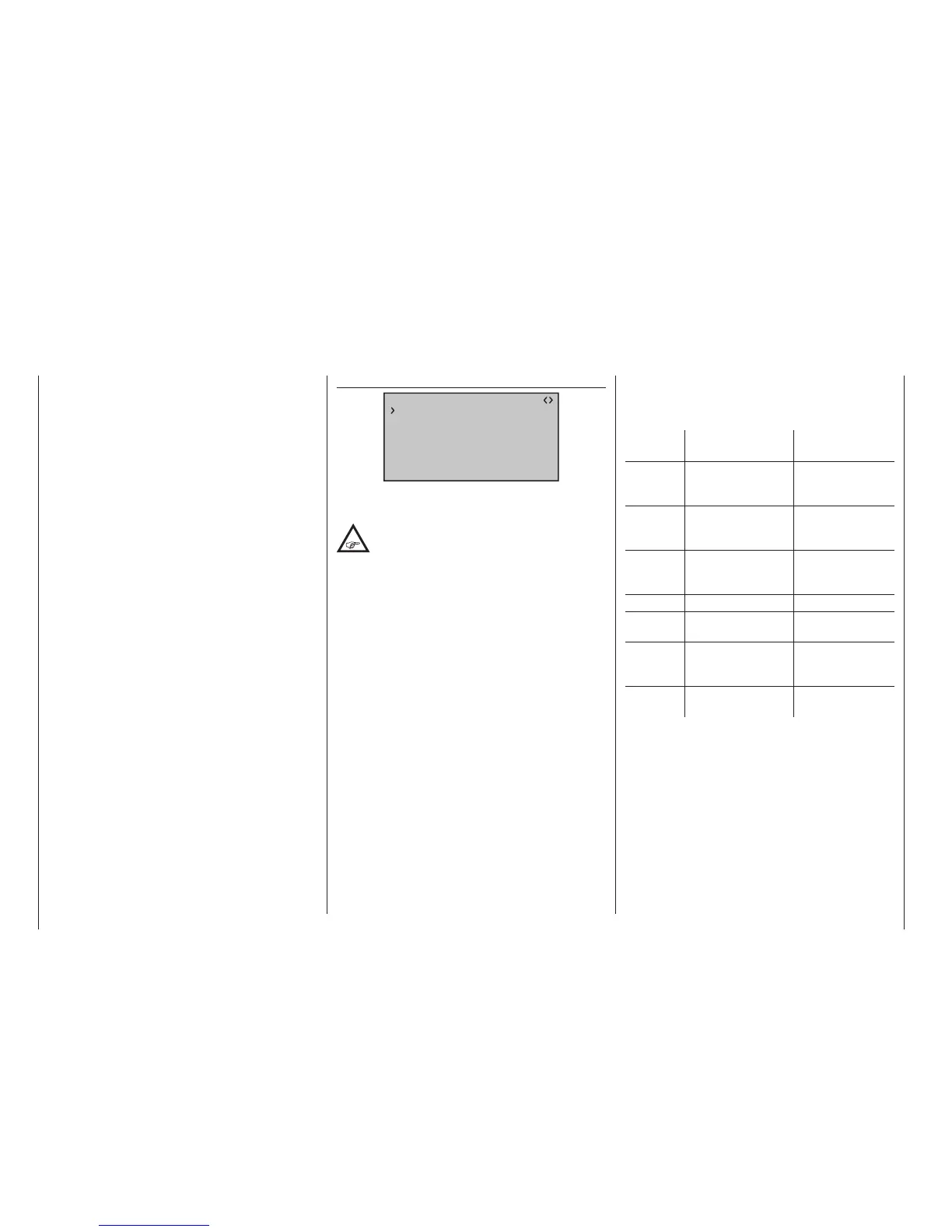

Value Explanation Possible

settings

OUTPUT

CH

Output channel

(servo connection of

the receiver)

1 … depending on

receiver

INPUT CH Input channel

(channel coming

from the transmitter)

1 … max. 12

MODE Fail-Safe mode HOLD

FAIL SAFE

OFF

F.S.POS. Fail-safe position 1000 … 2000 µs

DELAY Reaction time

(delay)

0.25, 0.50, 0.75

and 1.00 s

FAIL SAFE

ALL

Save of the Fail-

safe positions of all

control channels

NO / SAVE

POSITION Display of the saved

Fail-safe position

Between approx

1000 and 2000 µs

OUTPUT CH (servo connection)

In this line you select the respective OUTPUT CH (servo

connection of the receiver) to be set.

INPUT CH (selection of the input channel)

As already mentioned on page 236, the eight control

functions of the

mc-16 HoTT transmitter and the

mc-20 HoTT transmitter can be arbitrarily distribut-

ed to multiple receivers, if necessary, or even assigned

to multiple receiver outputs with the same control func-

tion.

Loading...

Loading...