o. Maintain the horizontal position of cylinder , install the sleeve and clutch disk assembly on the cylinder; ensure the top of

washer and external hole of cylinder are in order until the sleeve can contact the C2 wave plate.

Caution:

For the C2 wave spring is compressed and the clutch disk can endure the weight of 19.6N. The dimension form the lower

side of C2 pressure disc to the gear selection steel plate is 1.4

1.8mm. if the clutch need to start the accuracy from the

top of pressure plate, then the accurate value should be the actual size of pressure plate plus 1.4 1.8mm.

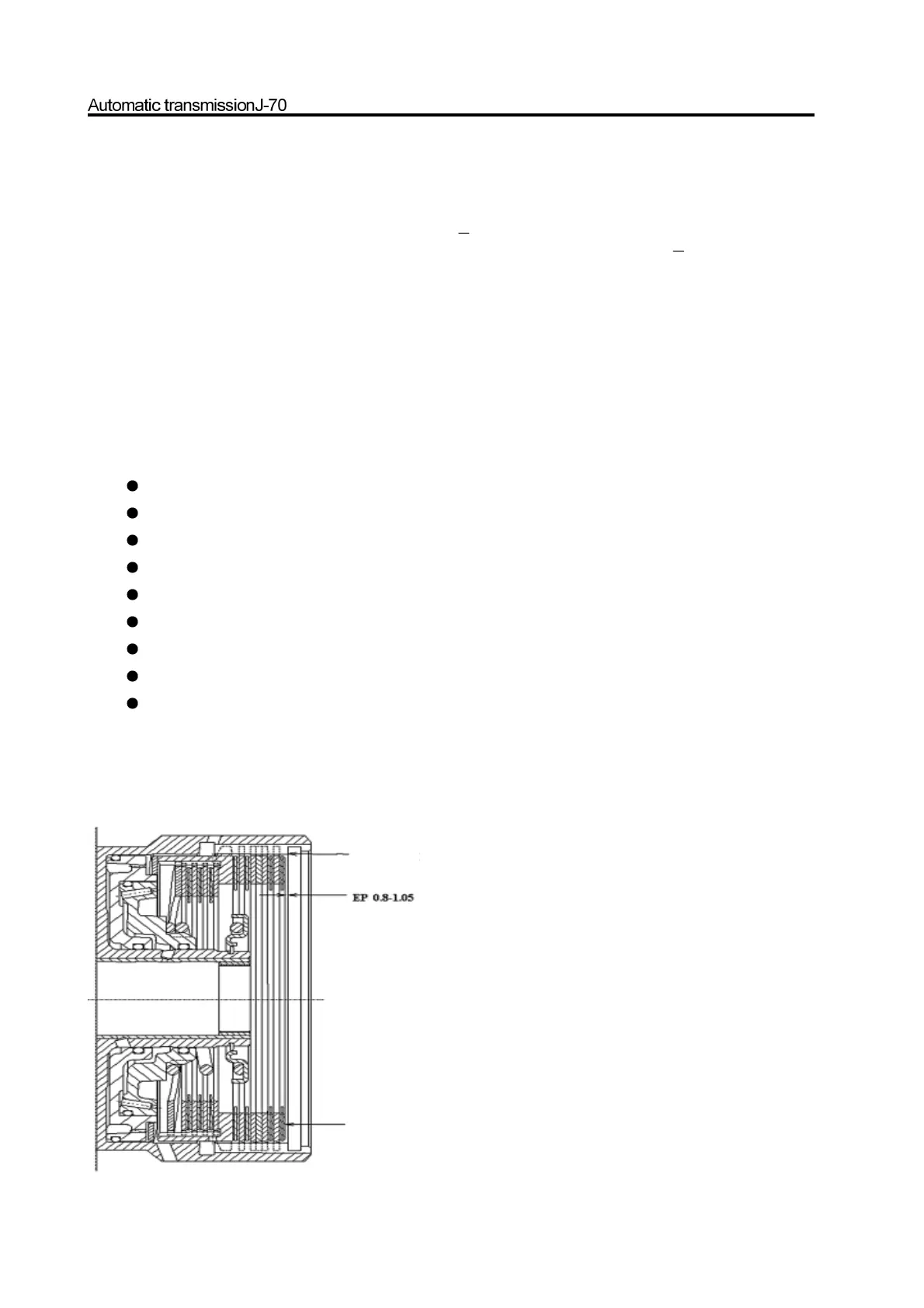

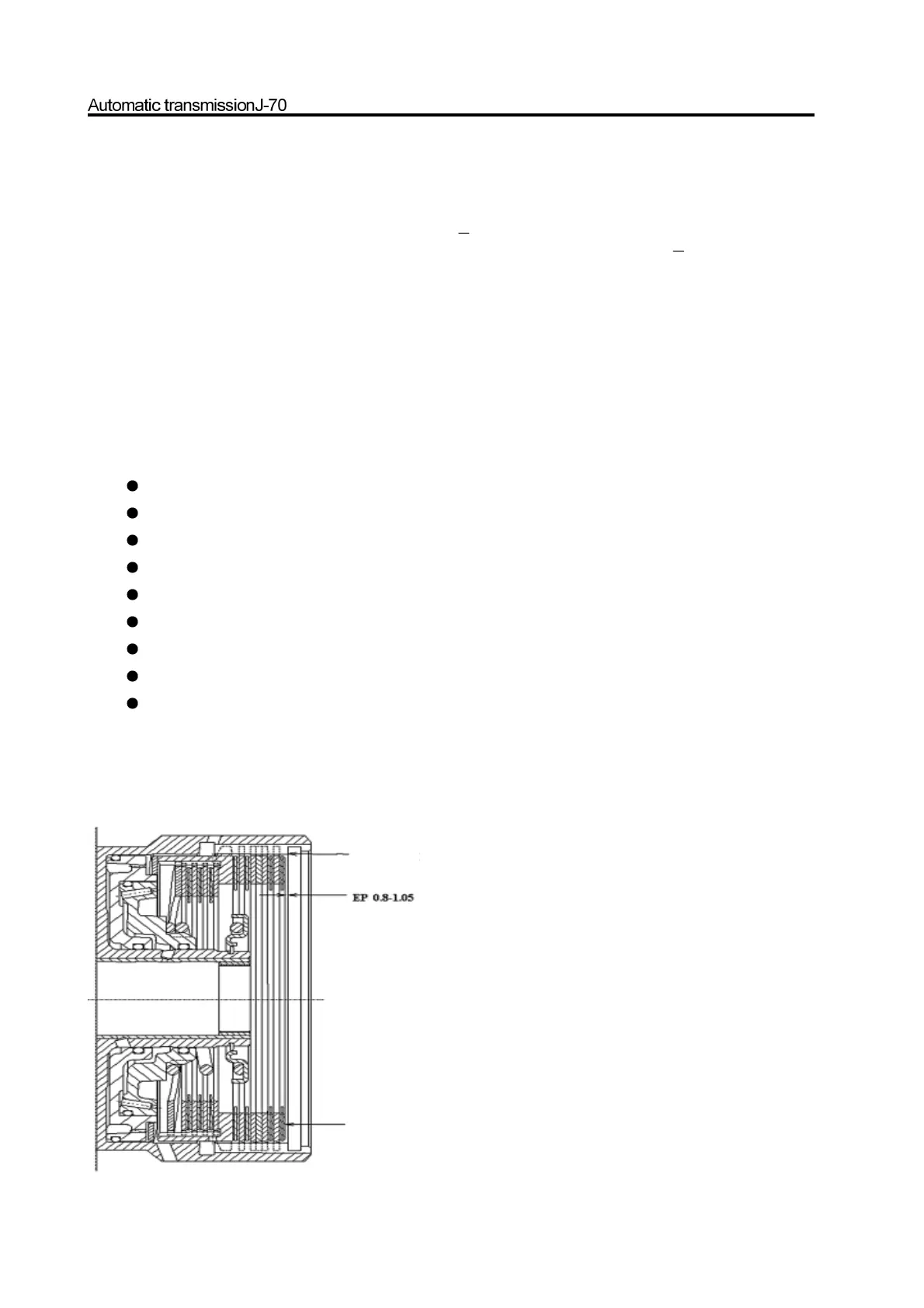

p. Use the special tools to check the C4 clutch assembly. Refer to Figure 8.25.

Caution:

It should take out the clutch clearance assembly before immerse the assembly into the automatic transmission fluid

(ATF).

q. Use the gear selection plate to reach the correct specification. If need to install the new friction disk, it should remove the

clutch assembly and immerse the friction disk in the automatic transmission fluid for 5 minutes at least before the installation.

Reinstall the sleeve and clutch assembly and place it in the cylinder. Ensure the wave washer is arranged consisting with the

cylinder hole.

Install the clutch C2 disk in the cylinder according to the following procedure:

friction disk

steel disc

friction disk

steel disc

The steel disc transmission use the G32 model engine; the 5

th

friction disk should replace the steel disc (reference table 9.3).

steel disc (optional)

friction disk

steel disc (optional)

friction disk

Caution:

For the clutch assembly can endure the weight of 19.6N, the dimension from the clutch C3 wheel axle to the friction disk

should be within 0.80-1.05mm.

r. Use the tool to test the clutch assembly; ensure the weight is in the acceptable range. Refer to Figure 8.26.

C3 hub positioning

clutch C2 loading

Figure 8.26 C2clutch assembly

Loading...

Loading...