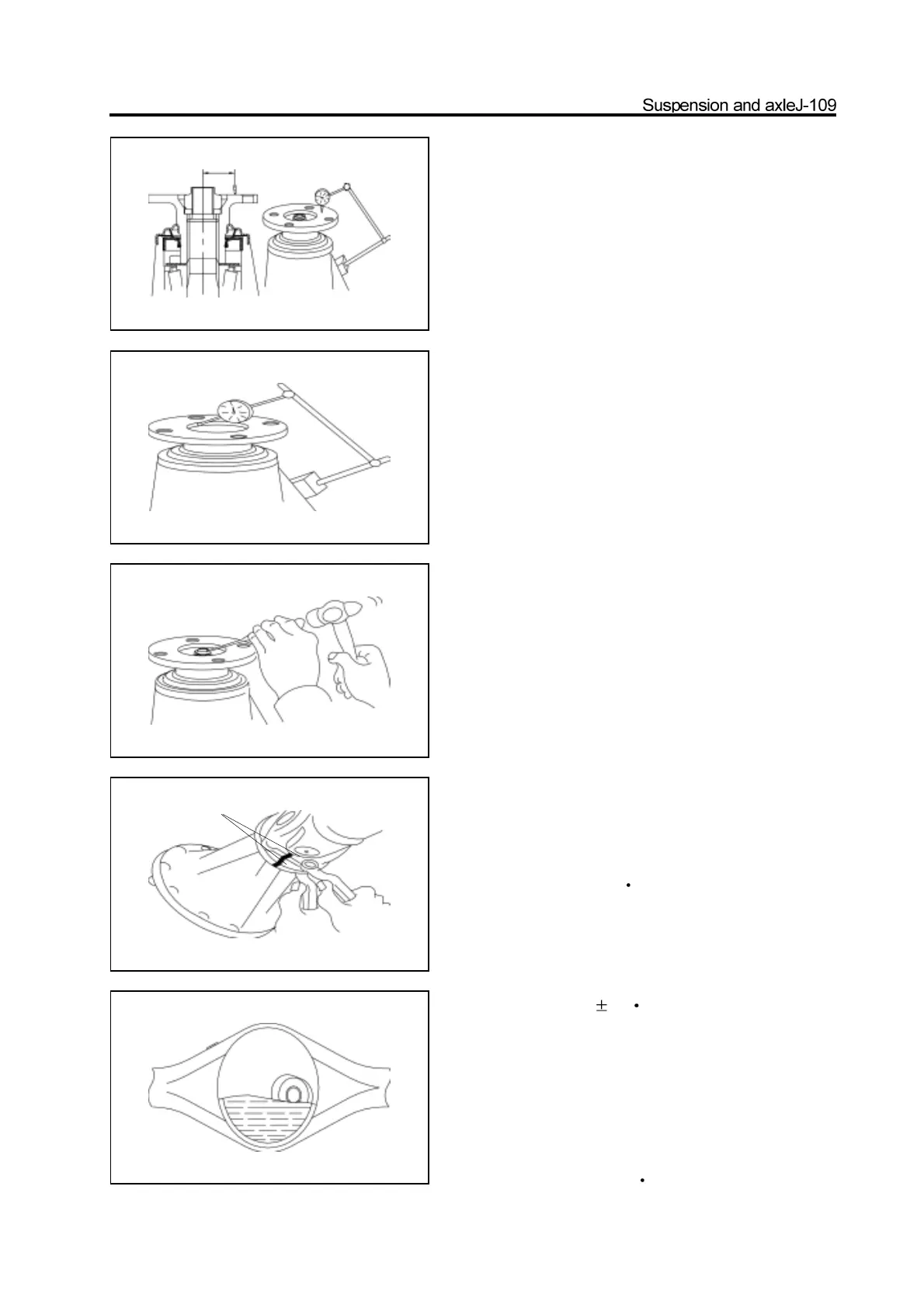

17. Check and adjust the run-out of flange.

a.Adhere the dial indicator base on the reducer housing; make the

probe of dial indicator contact with the end surface of flange;

rotate the flange and watch the rotation range of the dial.

Full run-out tolerance of end surface: 0.10mm

b.Adhere the dial indicator base on the reducer housing; make the

probe of the dial indicator contact with the inner diameter of

flange; rotate the flange by hand , and watch the rotation range of

the dial.Radial full run-out tolerance: 0.10mm

18. Rivet the nut of drive bevel gear

Installation of reducer and differential assembly

1.Install the new stiffening ring

2.Install the reducer and differential assembly

Install the reducer and differential assembly in the rear axle housing;

place the washer and nut. Tighten the nut to the specified torque.

Tightening force: 18-25N

m

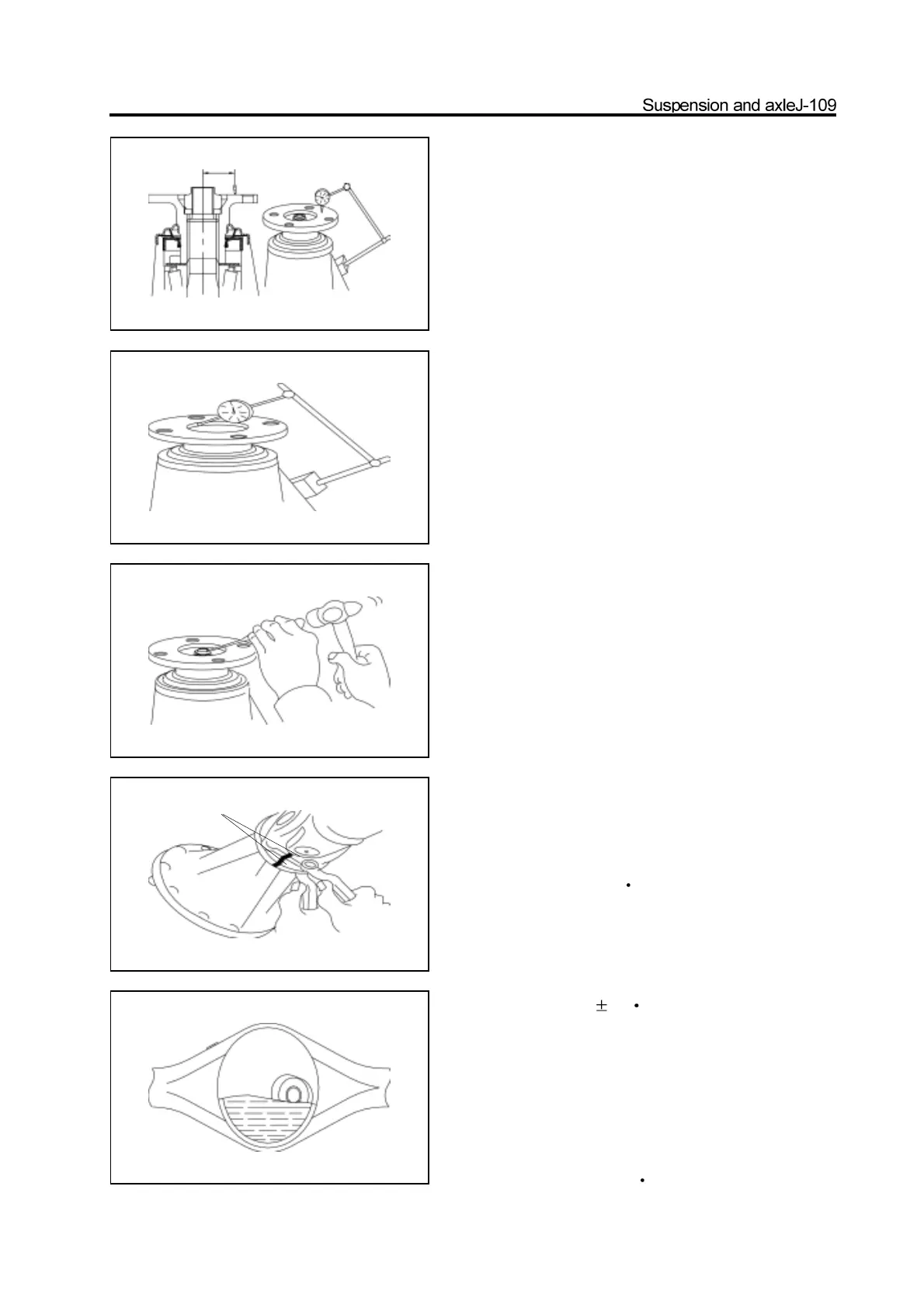

3.Install the reducer and differential assembly flange

on the drive shaft flange and align the assembly

mark; use four bolts and nuts to connect them.

Tighten the bolt and nut to the specified torque.

Tightening force: 78

5N m

4.Install the oil drain plug; fill the differential with the

gear oil

oil number : GL-5 hyperbolic gear oil

Viscosity: SAE80W/90

Amount: Filled with oil until the oil flow out from the oil filling

port.

Tighten the oil filling plug.

Tightening force: 140-150N

m

assembly mark

Loading...

Loading...