limitation limitation

Check and repair of rear axle components

1. Check the rear axle and flange for wear, damage

and run-out.

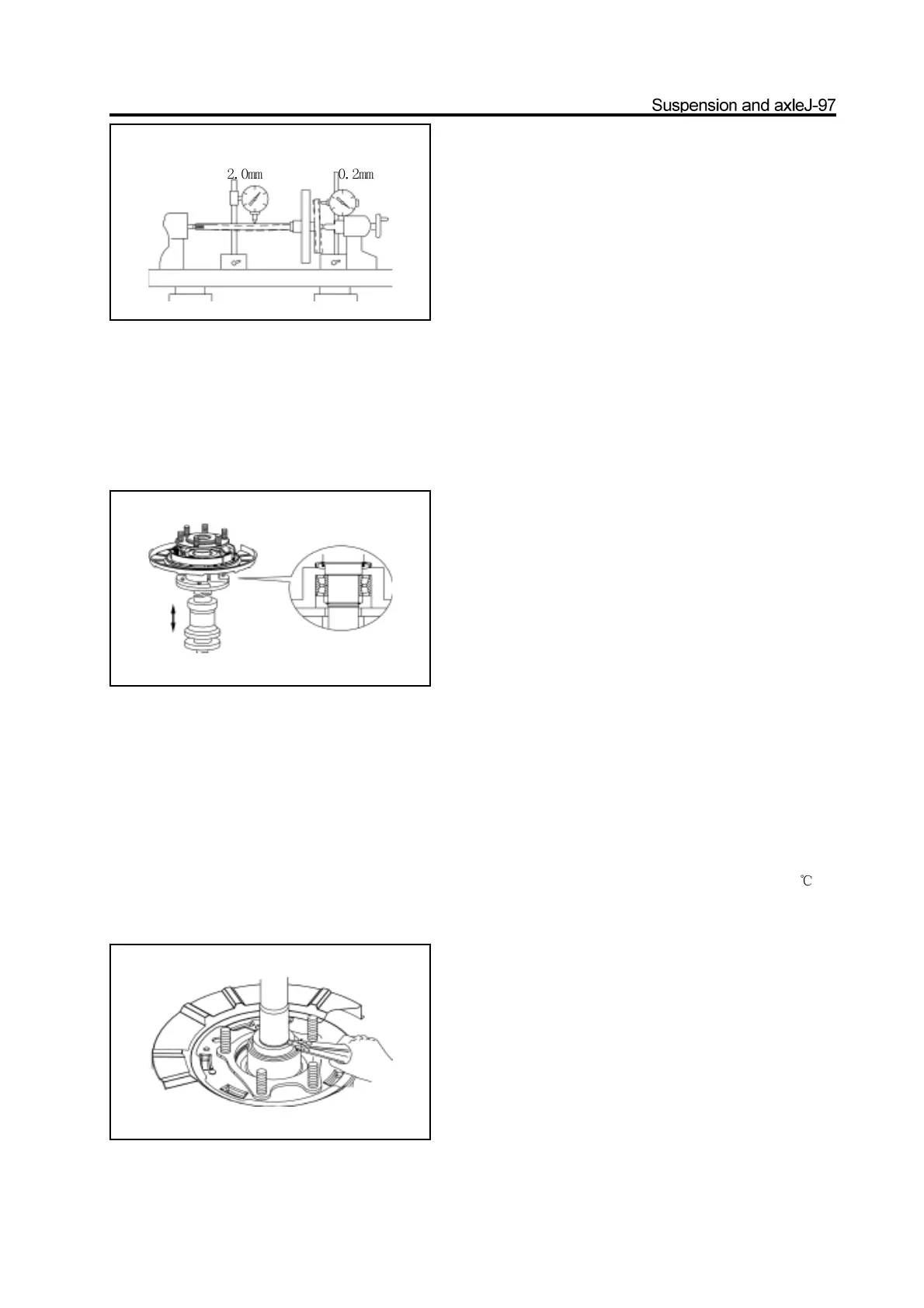

Max. Run-out of axle: 2mm

Max. Run-out of flange: 0.2mm

It should replace the rear axle if the rear axle or flange is worn or

damaged, or the measured run-out is beyond the specified value.

2. Check the external oil seal

a. Check for the wear or damage; especially for the lip of oil seal.

b. Replace it if necessary.

3. Check the bearing and oil seal holder

Check for wear and damage, replace it if necessary.

4. Remove the bearing and oil seal holder

a. Move the brake and oil seal pressing block to the limit position

along flange direction; move the external oil seal to the limit

position of oil seal.

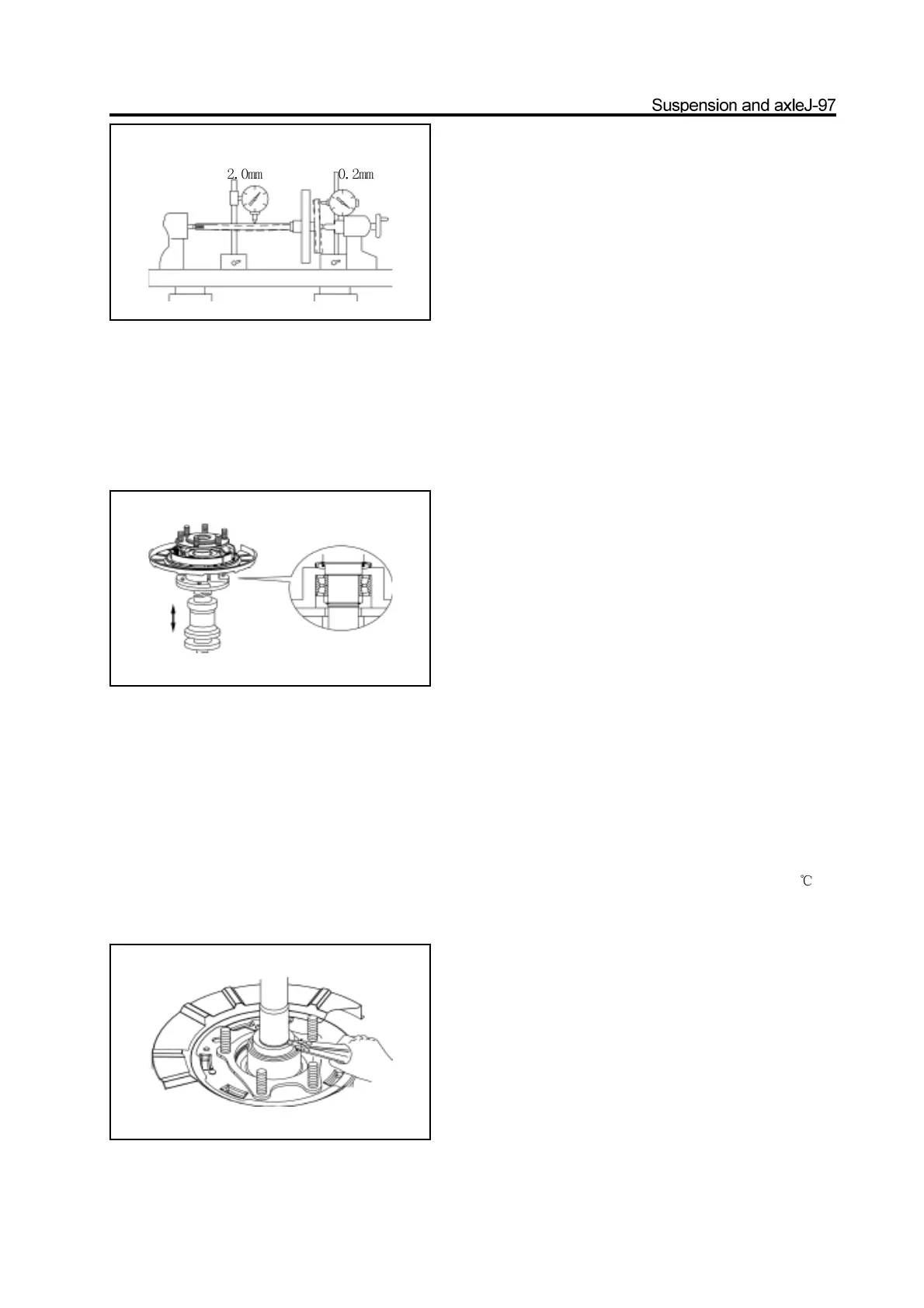

b. Place the hook of the special tools in sequence, the position is

shown as figure; make the hook holds the bearing tightly; then

use the bolt to connect the hook to the hammer fixedly; at last,

place it on the pad with halfaxle spline end facing ground.

c. Hold the hammer to beat downwardly with force for several

times to remove the bearing and oil seal holder.

Caution: Do not damage the oil seal .

5. Install the new external oil seal

a. Clean the semiaxle.

b. Coat the lip of external oil seal with proper HP-R grease.

Caution: When install the oil seal, the lip of oil seal must not

contact the semishaft to avoid scratching the oil seal .

6. Replace the bearing and oil seal holder

a. Heat the oil seal pressing block in 22# engine oil to 100 .

Caution: The end of oil seal pressing block with larger chamfer

faces the halfaxle spline. Install it immediately after taken out.

b. Use the hydraulic press to install the new bearing and new oil

seal pressing block by press.

7. Install the circlip

Use the circlip pliers to install the new circlip in the slot of semiaxle.

Loading...

Loading...