b. Check the damage of external diameter and central support diameter of C3 cylinder sleeve. Coat the sealing ring with the

automatic transmission fluid and install it on the C3 cylinder groove.

c. Check the condition of reverse central gear spline, notch and thrust surface; coat the O-ring with transmission liquid and install

it in the reverse sun gear groove. Use the Vaseline to lubricate the C3 washer and install it in the reverse sun gear.

d. Install the reverse central gear in the C3 cylinder; ensure the O-ring is compressed properly but not excess.

Caution:

The O-ring notch can not be bent.

e. Coat the C3 piston O-ring with the transmission liquid and install the small O-ring on the C3 piston inner ring; install the large

O-ring on the C3 piston external ring.

f. Check the piston drainage hole for cleanness and block material.

Caution:

Must not remove the O-ring without permission.

g. Install the C3 piston on the cylinder until the external diameter of piston enters into the inner diameter of cylinder.

h. Install the spring and spring retainer on the piston. Use the tools to press down the spring to install the ring spring better.

Ensure the ring spring is installed in the groove fixedly, then remove the tools.

i. Install the C3 wave plate on the C3 piston surface; ensure the a hole on wave disc of C3 piston surface is not in line with the

piston hole.

j. Install the clutch disk and other disc in the following sequence:

steel disc

friction disk

steel disc (optional)

friction disk

steel disc (optional)

friction disk

k. Adjust and install the pressure disc; make its counterbore is opposite with the clutch disk.

l. Install the ring spring.

Caution:

For the clutch assembly can endure the weight of 19.6N. so the clearance between the screw and top of preset disc should

be 1.20-1.45mm.

m. Use the tools to check the clearance of clutch C3, refer to Figure 8.29. The method is as follows (only use the weights):

Place the weights on the pressure disc and measure the distance between the bottom of cylinder and top of pressure disc.

Record the data.

Remove the weights.

Lift the weights plate and press down the ring spring; measure the distance between the bottom of cylinder and top of

pressure disc

Record the data.

The clutch assembly clearance can be acquired by 1

st

record minus 2nd record.

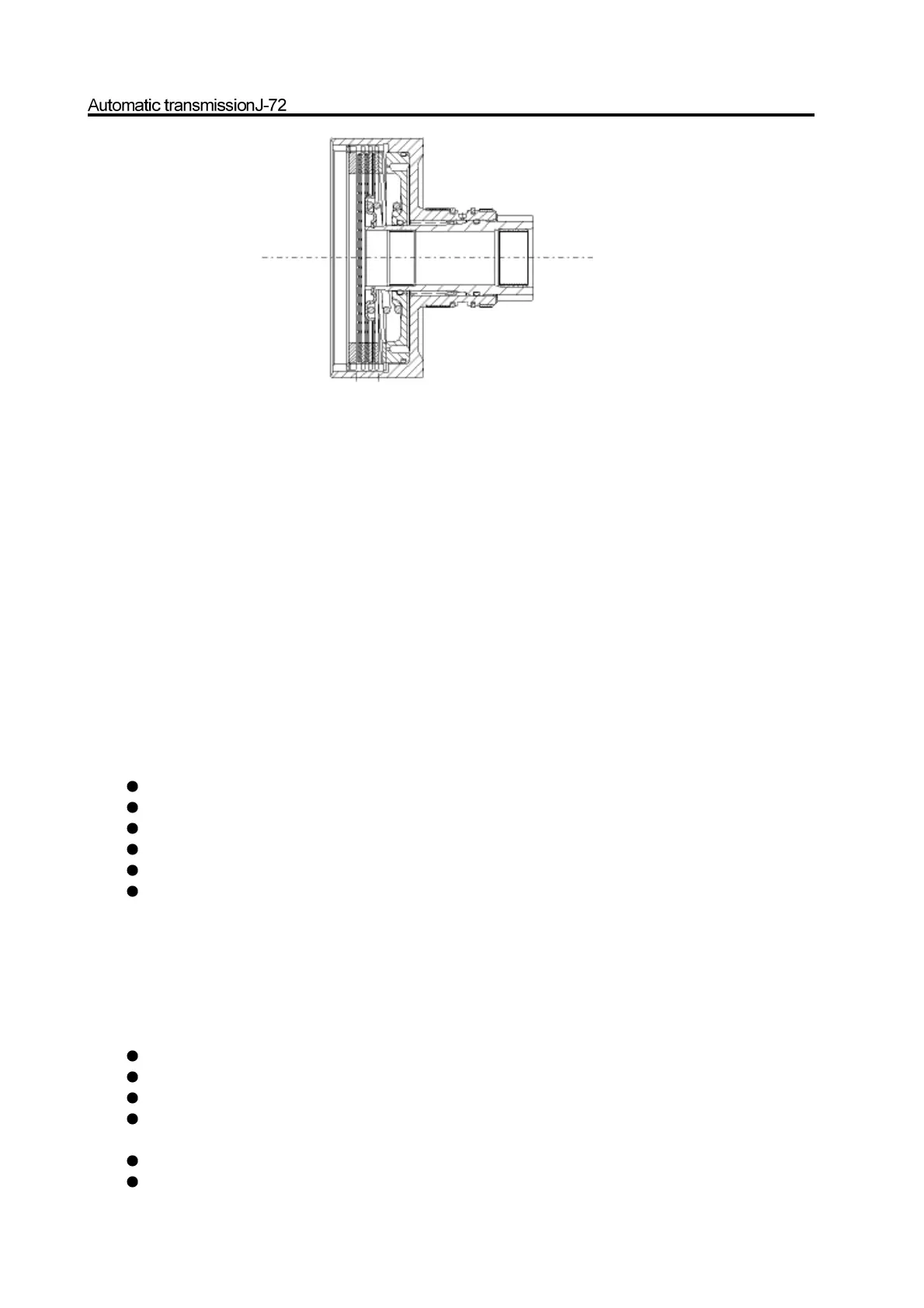

Figure 8.28 clutch C3 and reverse central gear

Loading...

Loading...