f. Make the installation of oil bottom shell is proper for transfer case and the tighten the safety valve according to the

specification and sequence (Refer to Figure 8.61). do not distort it.

16.Torque converter and support sleeve assembly

Install the hydraulic torque converter and housing assembly, the procedure is shown as follows:

a. Install the hydraulic torque converter housing on the main case.

Caution:

All hardware should be installed correctly and comply with the specification.

b. Use the Loctite243 or equivalent to fix the torque converter housing; install and tighten it to standard specification.

c. Install the torque converter; ensure the pump gear sealing is installed correctly.

17. Rear wheel drive mode of output ring flange assembly

Assemble the output shaft assembly, the procedure is shown as follows:

a. Place the paw of transmission operating rod on the parking position and lock the output shaft.

b. Wash the output shaft upper line; use the loctite243 or equivalent.

c. Install and tighten the ring flange, O-ring and nut.

Caution: In the heavy steel slide plate, place the ring flange on the upper nut; avoid the damage of bearing.

d. Tighten the nut on the output shaft

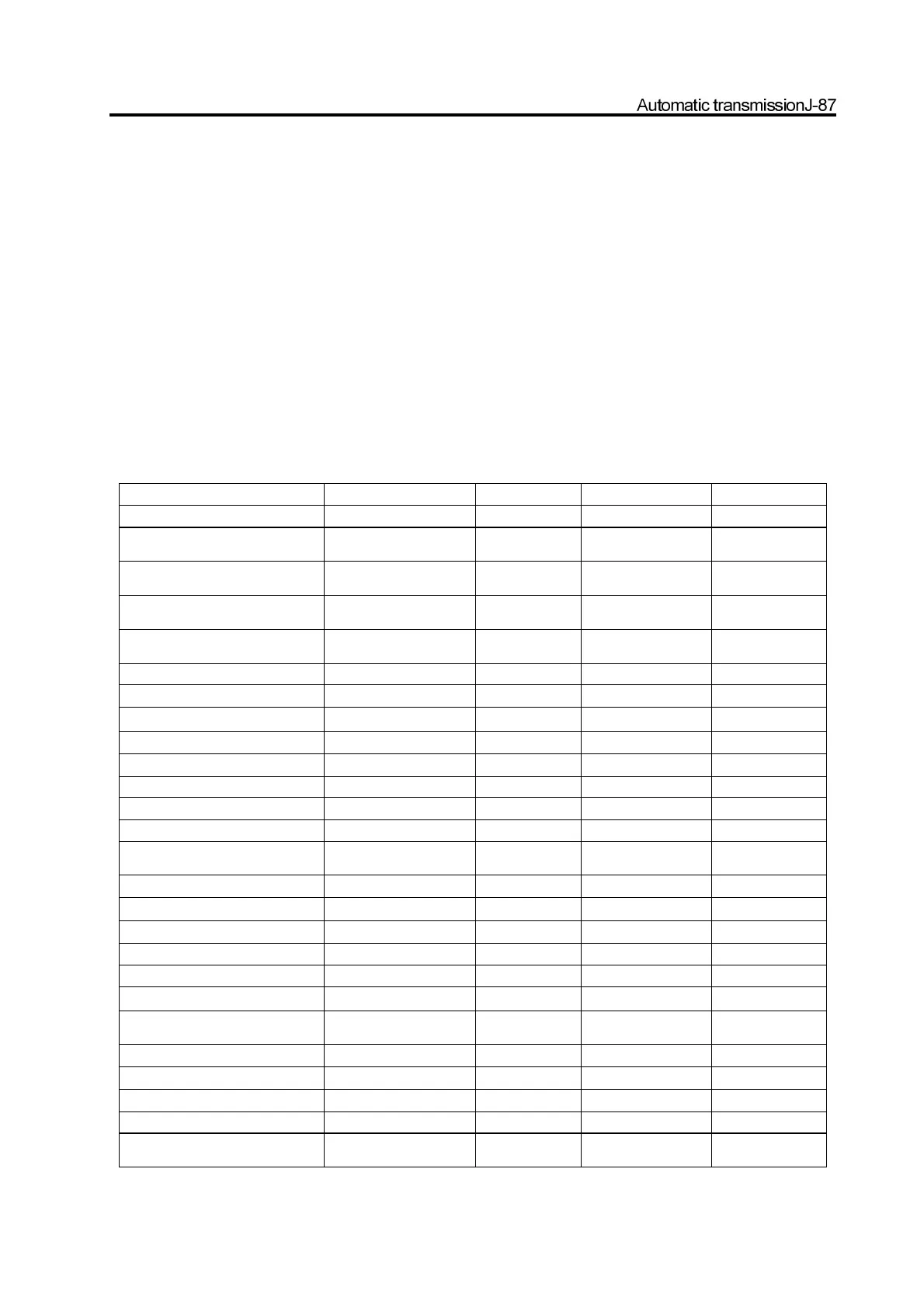

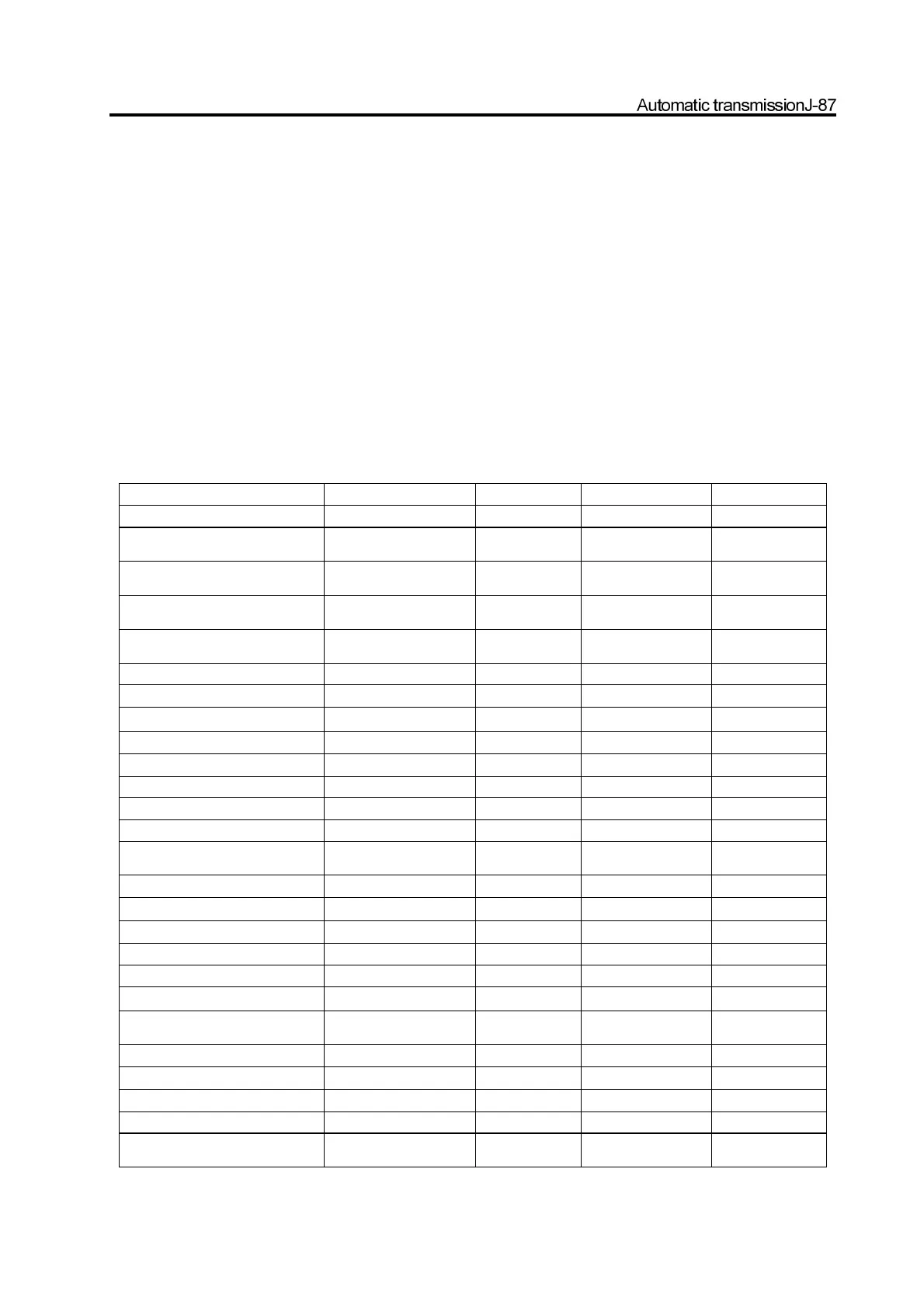

Torque type specification N.m Ft/lb

transmission assembly

torque converter housing to

housing

M12× 32

4, 8or 9 54-68 40-50

rear end housing to housing

-Chairman

M12× 32

4 54-68 40-50

Connector housing to housing

-4W D

M8× 25

10 35-40 26-30

rear end housing to housing

-2W D

M8× 25

10 35-40 26-30

rear servo cover to housing

M8× 25

6 30-35 22-26

Oil pan to housing

M6× 16

9 4-6 3-4.5

Oil cooler pipe connection

2 40-45 29.5-33

Valve to housing

M6× 26

7 8-13 6-9.5

Valve to housing

M6× 45

5 8-13 6-9.5

Brake bar spring

M8× 16

1 20-22 15-16

central support to housing

M10× 34

2 20-27 15-20

Cam disc to housing

M8× 16

2 16-22 12-16

Gear-position sensor to

housing

10-24× 13

2 4-6 3-4.5

Output shaft lock nut

M24× 1.5

1 100-110 74-81.5

oil filling plug M20 1 30-35 22-26

Pump housing assembly

Pump to pump cover

M8× 55

5 24-27 18-20

Pump cover to housing

M8× 40

6 24-34 18-25

Pump cover to housing

M8× 58

2 24-34 18-25

Pump cover disc to pump

cover

M6× 16

5 13-16 9.5-12

Pump cover disc to crescent

M6× 54

1 13-16 9.5-12

Valve assembly

Upper valve to low er valve

M6× 30

24or 25 11-16 8-12

Line socket M6 1 4-7 3-5

solenoid valve (on/off type

and VPS, including S7)

M6× 16

7 8-12 6-9

Table 8.1 Torque specification

Loading...

Loading...