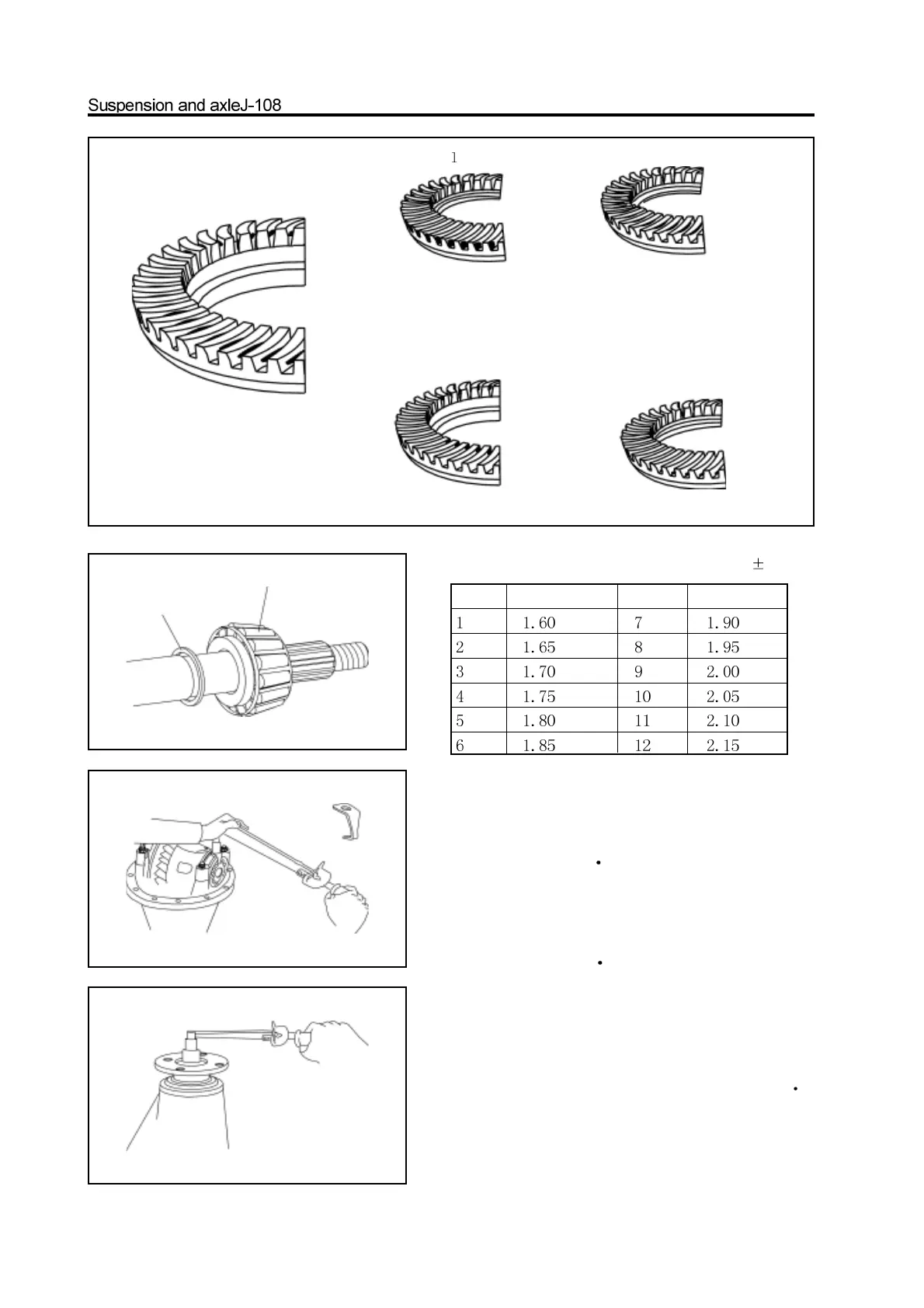

sound contact

toe contact

dedendum contact

arge end contact

small end contact

select the shim which can make the small drive gear

close to the driven bevel gear

select the shim which can make the small drive gear away from the driven bevel gear

Select the proper washer from the table for correction if the intertooth

contacting status is bad. The thickness tolerance of washer is

0.01mm.

15. Install the stop washer and stop plate

a. If the drive and driven gear engagement mark meets the requirement,

then use the hand hammer and punch to lock the stop washer.

b. Install the stop plate, spring shim and bolt; tighten the bolt.

Tightening force: 18-25N

m

c. Use the punch and hand hammer to knock the lower end of stop

plate in the adjusting ring hole.

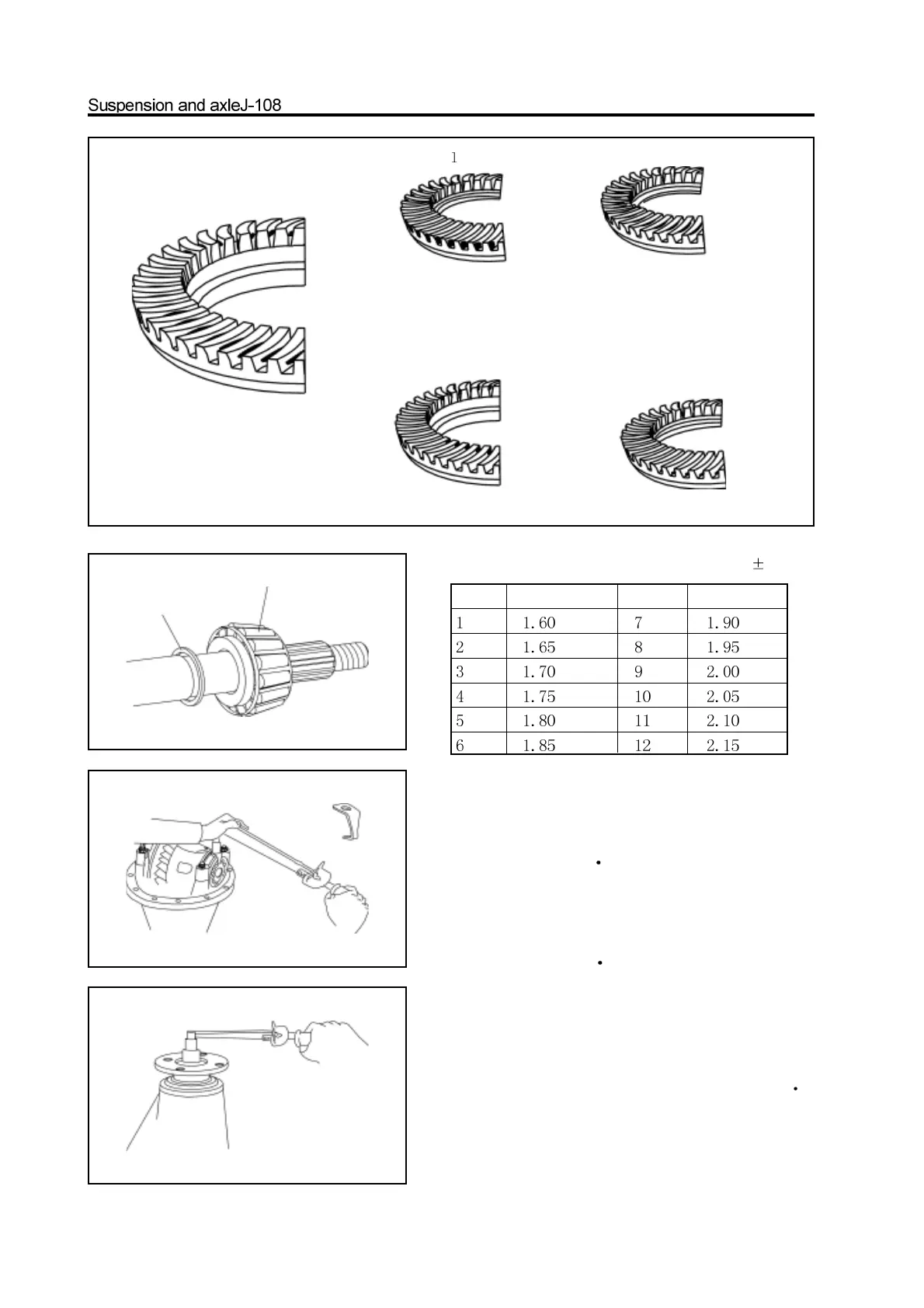

Set NO. Thickness Set NO. Thickness

16. Measure the total pre-applied load

Pre-applied load : 1.8-2.4N m

If the pre-applied load is beyond the specified; it should replace the

shim between the spacer and rear bearing until meet the requirement.

a. It should replace the adjusting washer if the pre-applied load is

more than specified value.

b. If the pre-applied load is less than specified value, it can retighten

the nut slowly and the torque should be no more than 160N m.

Caution: When tighten the nut, if is beyond the Max. torque, re-

place the adjusting washer and repeat the pre-applied load process.

Do not reduce the pre-applied load by the method of screw off the

drive gear nut to loose.

washer

rear bearing

Loading...

Loading...