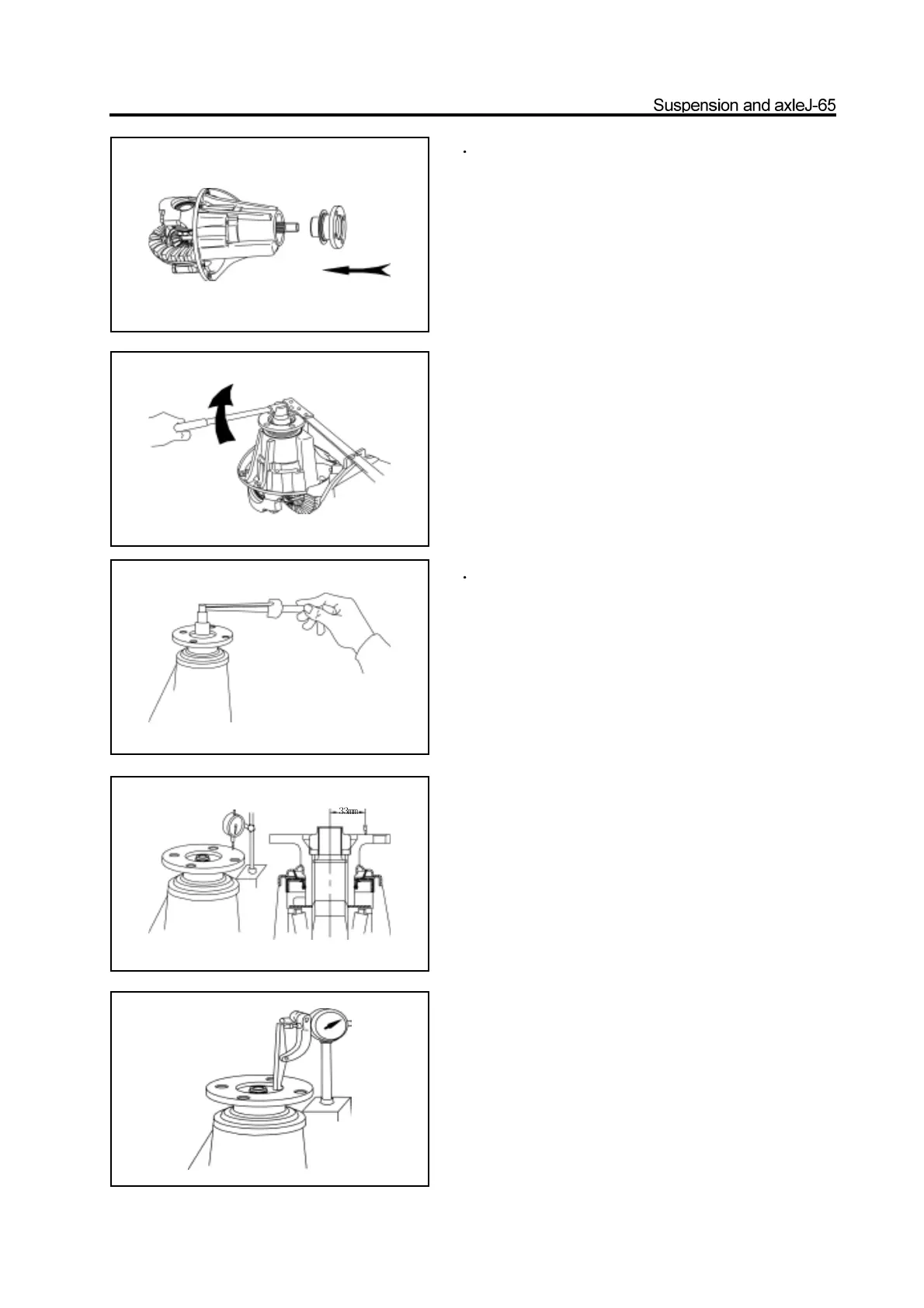

8 Install the drive gear flange and dustproof cover

assembly

a. Match the drive gear flange and dustproof cover assembly on

the front drive gear.

b. Coat the new nut with the lithium base grease.

c. Use the special tools to clamp the flange and tighten the nut

to the specified torque.

Tighten torque:140-160N.m

a. Use the torque meter to measure the pre-applied load of the

gap between the drive bevel gear and driven bevel gear.

pre-applied load: 1.2-1.7N.m

b. Is should be replaced by the thicker washer if the pre-ap

plied load is more than specified value

(The step of thickness of washer is 0.03mm)

c. Is should be replaced by the thinner washer if the pre-applied

load is less than specified value. Repeat the previous

operation until meet the requirement.

Caution: Do not reduce the load by loosing the nut.

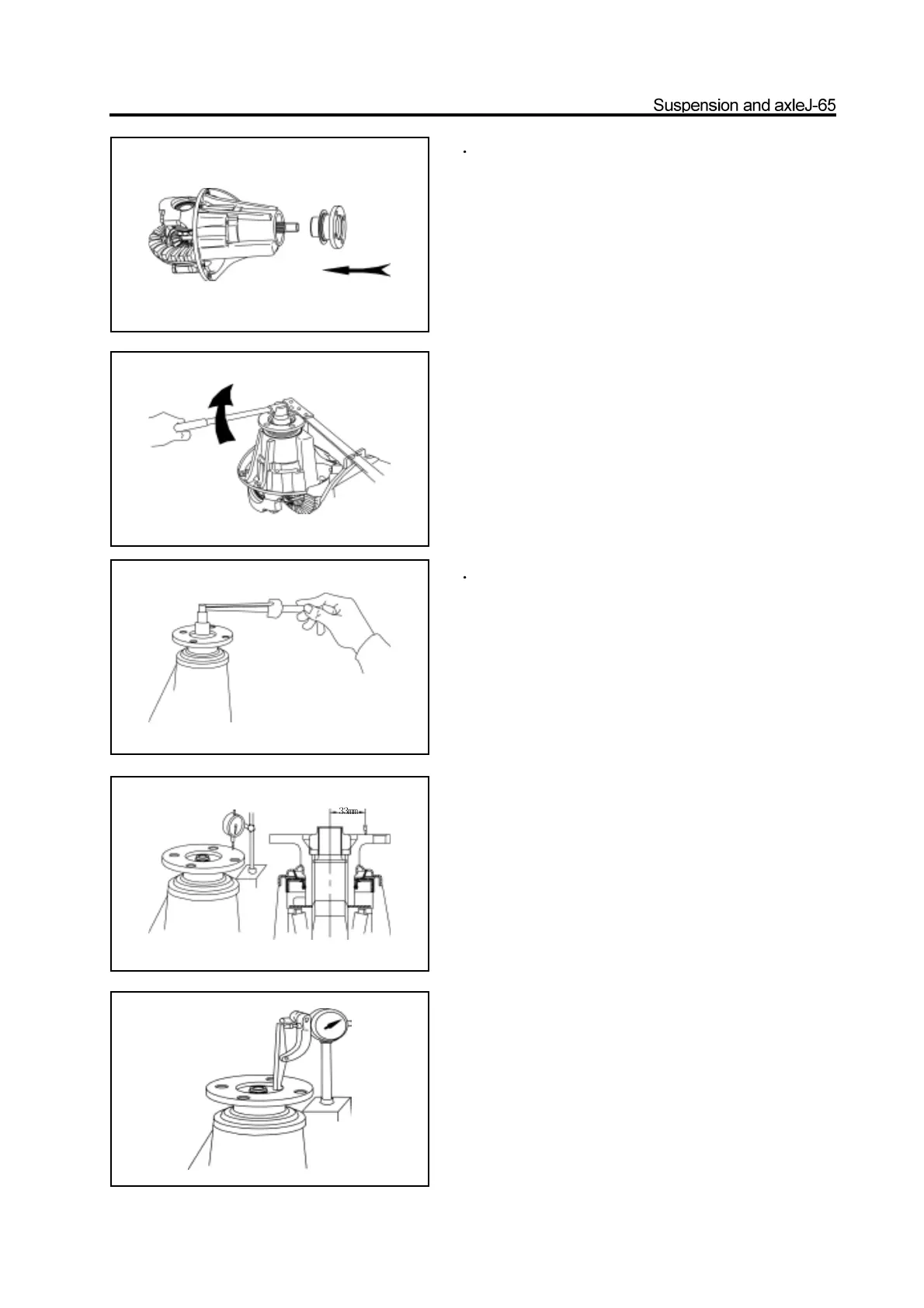

10. Check the axial and radial run-out tolerance

offlange.

a. Use the dial indicator to measure the axial runout of flange.

Max. axial runout: 0.1mm

b. The max. radial run-out tolerance is 0.1mm

It should check the bearing if the radial run-out tolerance is large.

9 Adjust the pre-applied load of the drive

bevelgear bearing

Loading...

Loading...