9. Remove the sealant on the matching surface

between the flange and electric clutch housing by

knife.

Caution: Do not scratch the matching surface.

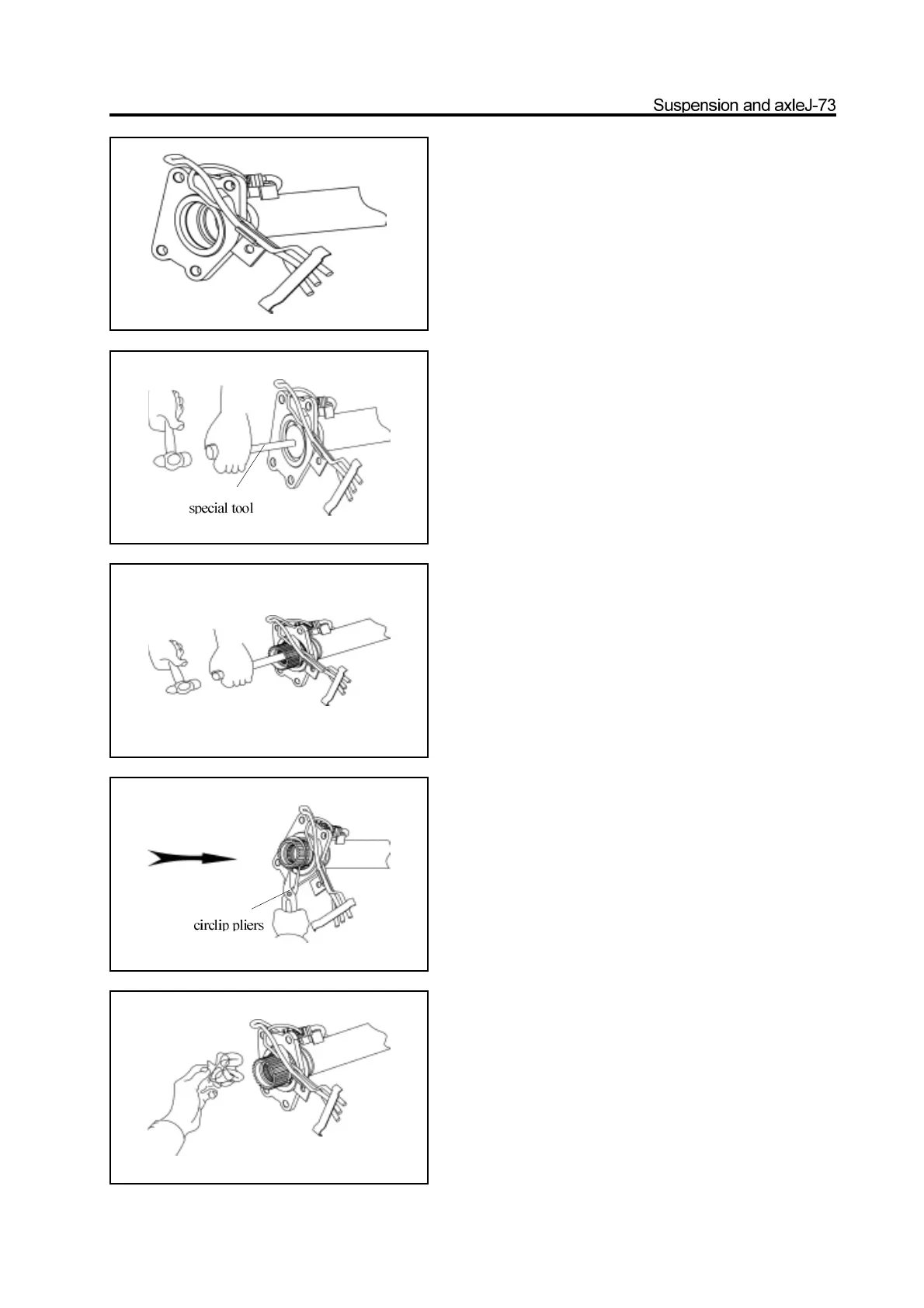

10. Use the special tools to knock the new seal in the

oil seal position in flange.

Caution: Before install the new oil seal, it should

coat the lip with thin lithium base grease, and the oil

seal should be in alignment position.

11. Insert the spline of small end of major semiaxle

in the spline of front reducer half axle gear slightly,

then use the brass bar and hand hammer to knock it

in.

Caution: When knock in the major semiaxle, must

not damage the inside needle bearing of large end

spline of major semiaxle.

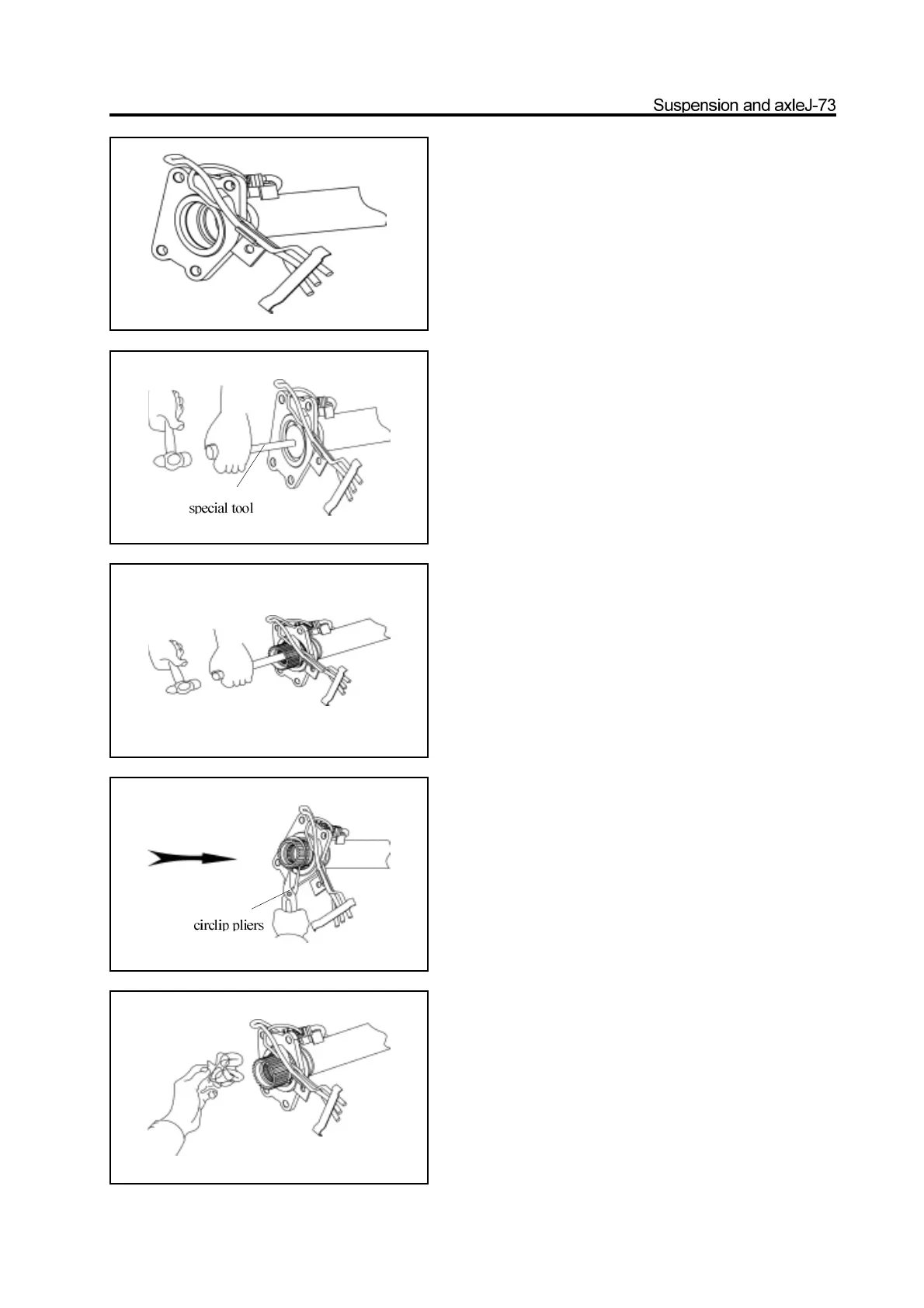

12. Use the circlip pliers to install the circlip in the

flange and clamp the bearing outer race.

Caution: The circlip should be replaced if it has

serious deformation.

13. Use the clean cloth to wipe the matching surface

of flange and electric clutch housing respectively.

Loading...

Loading...