261

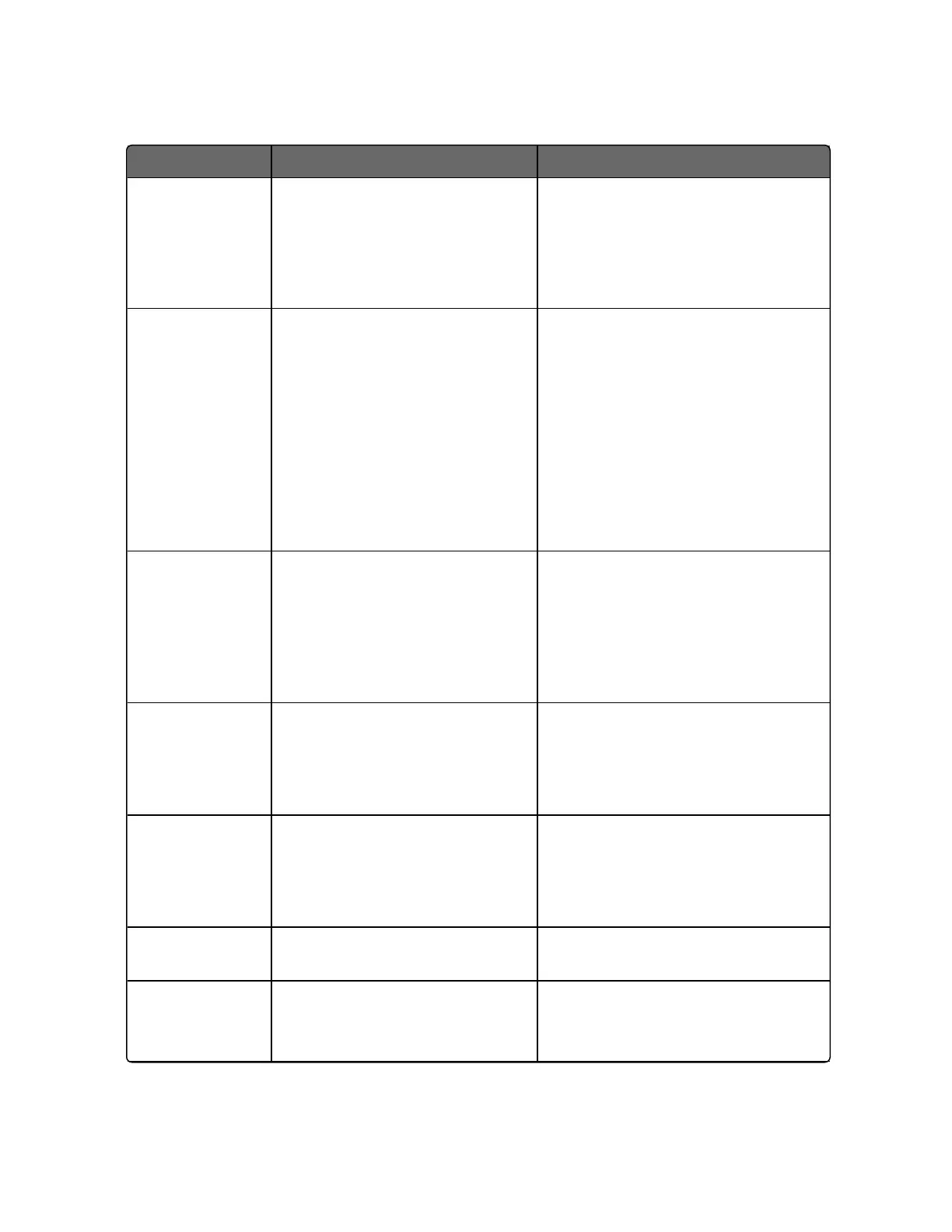

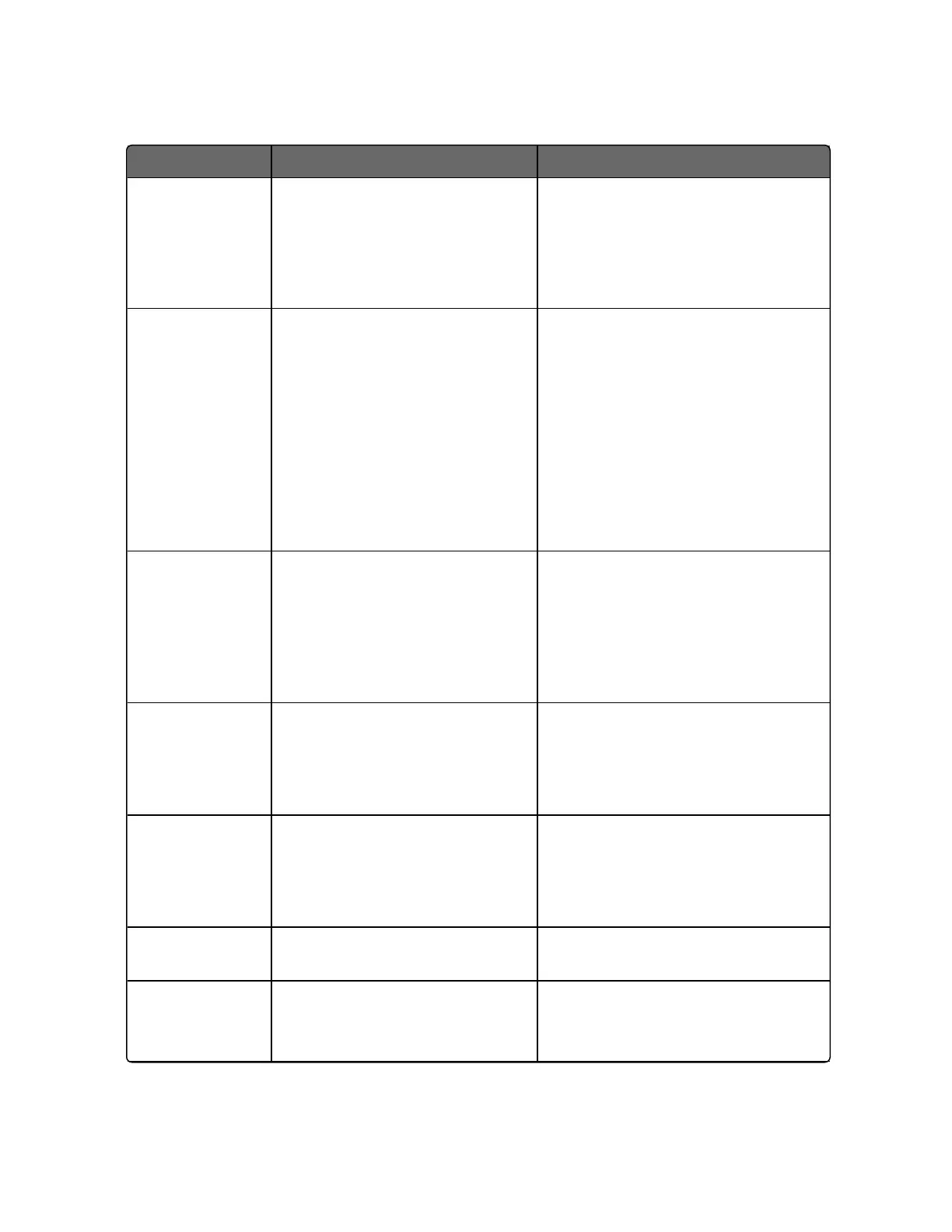

Lower Display Reason for Failure How to Correct the Problem

high/low limit, Linear ±10%,

TC/RTD ±1%, Input Algorithm

0%.

PV = Input 1 x Ratio 1 + Input 1

BIAS

2. Make sure the Ratio and Bias

settings are correct.

3. Recheck the calibration. Use

Bias of 0.0.

Remote SP

Limit

RSP in engineering unit (with

ratio and bias) is out of limit.

RSP limit is same as burnout

high/low limit, Linear ±10%,

TC/RTD ±1%, Input Algorithm

0%.

RSP limit shall not triggered

when RSP Source choose None.

RV = Input 2 x Ratio + BIAS

1. Make sure the input signal is

correct.

2. Make sure the Ratio2 and Bias2

settings are correct.

3. Recheck the calibration. Use a

Ratio2 of 1.0 and a Bias2 of 0.0.

Segment Error Setpoint Program start

segment number is less than

ending segment number.

Segment Error shall not

triggered when Setpoint

Program is disabled.

Check SP Program configuration.

See SP Ramp/Program Set Up

Group for more information.

Slidewire Calib

1. Input 2 Type is configured as

Slidewire.

2. Slidewire calibration never

performed.

Field Calibrate the slidewire. See

Position Proportional and Three

Position Step Output Calibration

for more information.

Slidewire Fail

1. Input 2 Type is configured as

Slidewire.

2. Position Proportional

slidewire input failure.

See Troubleshooting Procedures

for more information.

Sooting Percent Carbon falls outside

sooting boundary

Check process for correct

operation.

TC 1 Warning Thermocouple on Input 1 is

starting to burn out.

This diagnostic message means

that the controller has detected

that the thermocouple is starting

Chapter 8 - Troubleshooting/Service

Loading...

Loading...