43967002TH Rev.1

31 /

Oki Data CONFIDENTIAL

2. Theory of Operation

(1) Electro-photographic process

Outline of the electro-photographic process is described below.

1. Charge

Vol

tage is applied to the CH roller in order to charge the surface of the OPC

drum.

2. Exposure

The

LED head irradiates light in accordance with the image signal on the

charged surface of the OPC drum.

Amo

unt of charge at the irradiated segment on the surface of the OPC

drum is decreased in accordance with strength of irradiated light so that the

electrostatic latent image is created on the surface of the OPC drum.

3. Develop

The

charged toner is attracted by the electrostatic latent image on the OPC

so that the toner is developed on the OPC drum surface.

4. Transfer

A p

rint paper is overlaid on the OPC drum surface and the toner image is

transferred to a paper when electric charge is applied to the transfer roller

from the back of a paper.

5. Drum cleaning

The

drum cleaning blade removes the residual toner that is remained on the

OPC drum after image transfer.

6. Belt cleaning

The

belt cleaning blade removes the residual toner that is remained on the

belt.

7. Fix

Ton

er is fused when heat and pressure applied to the toner image on the

print paper.

2.1 Electro-photographic process system

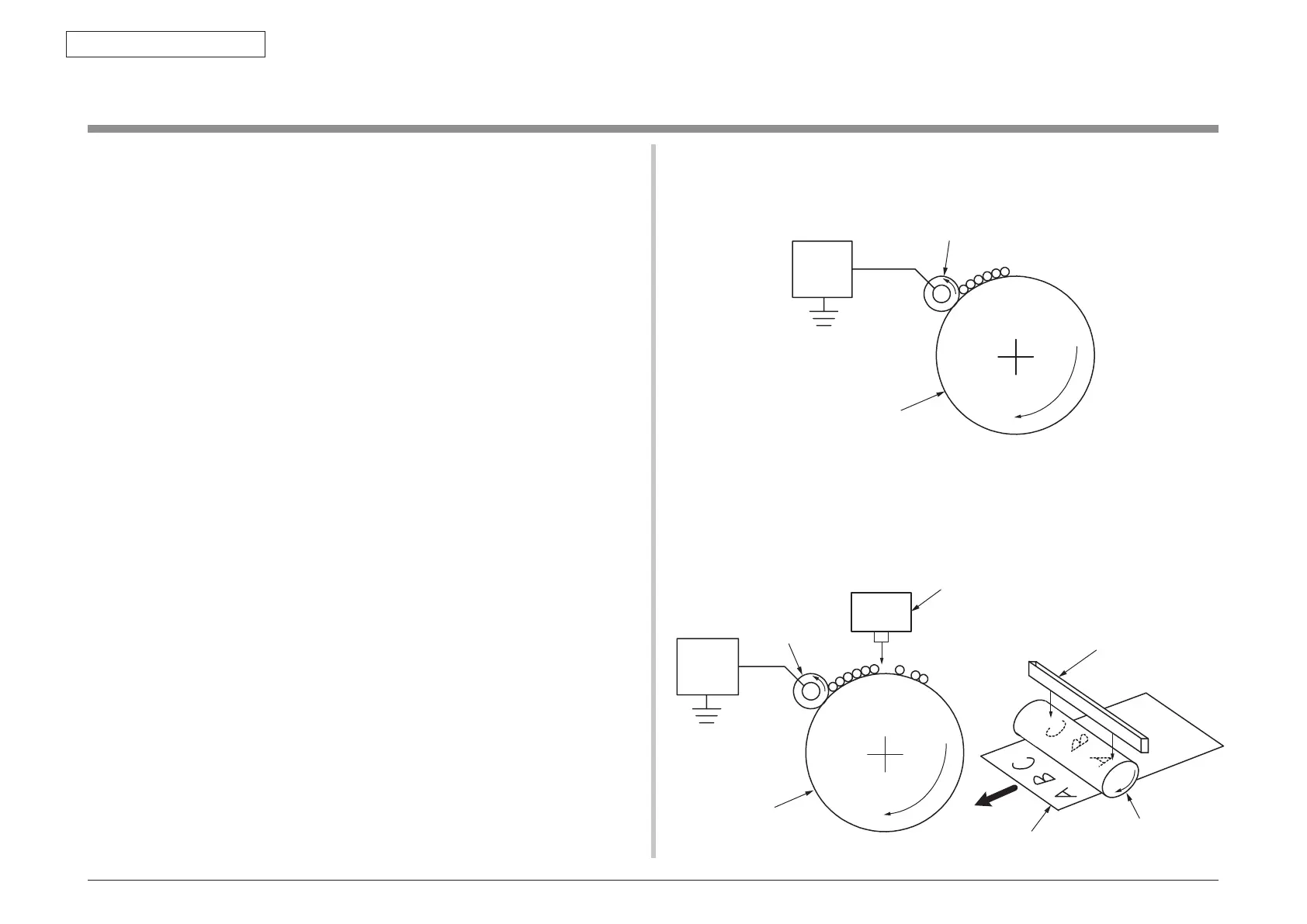

(2) Charge

Voltage is applied to the charge roller that is contacting with the OPC drum surface

so that the OPC drum surface is charged.

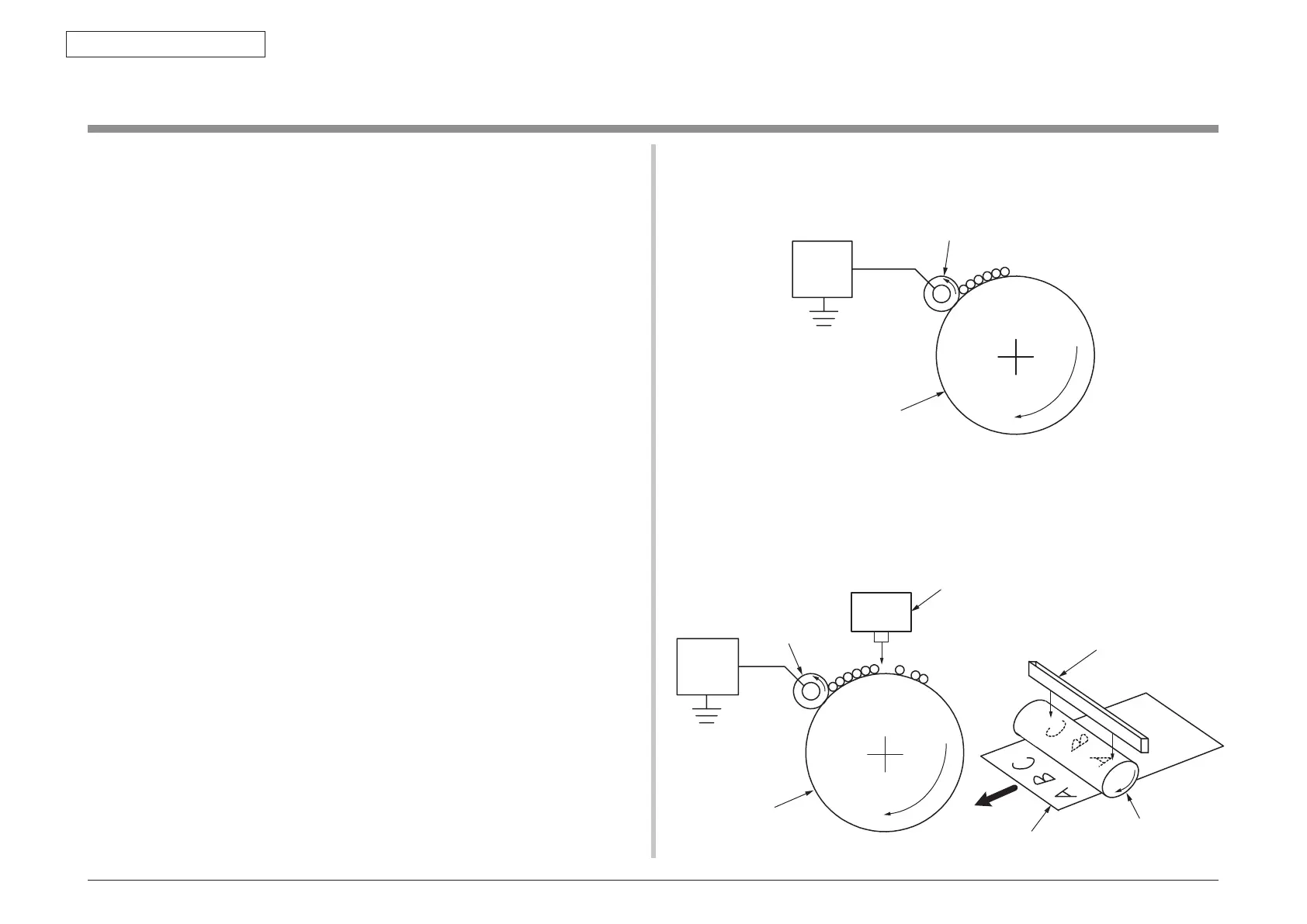

(3)

Exposure

The light that is generated by the LED head is irradiated to the charged surface of

the OPC drum. Amount of charge at the irradiated segment on the surface of the

OPC drum is decreased in accordance with strength of irradiated light so that the

electrostatic latent image is created on the surface of the OPC drum.

-

-

-

-

-

-

Power

supply unit

Charge roller

OPC drum

-

-

-

-

-

-

-

-

-

Power

supply unit

OPC drum

Paper

LED head

OPC drum

LED head

Charge roller

Loading...

Loading...