Oki Data CONFIDENTIAL

43967002TH Rev. 1

344 /

7. Troubleshooting

Note! Toner sensor operation check method using the SWITCH SCAN function of

th

e self-diagnostic mode.

(1) H

ow to check operation of the toner sensor at the printer side.

1. Status change of the toner sensor can be checked from the Operator

Panel using the self-diagnostic mode. First, switch the display to the

Operator Panel display. For the method of switching the display to the

Operator Panel display, refer to item 5.3.2.3 Switch Scan Test.

2

. Re

move the ID unit and the toner cartridge (TC) from a printer. There

is a window inside a printer opposing the ID side when viewed from

the front of a printer. The toner sensor is located inside the window.

3. Pl

ace a white paper 3 mm away from the sensor window. The white

paper should be placed in the manner of opposing the toner sensor.

4. Wh

en light is reflected by a white paper so that incident light falls on

the toner sensor, the Operator Panel display shows “L”. When the

paper is moved so that any light is not reflected by the paper so that

the incident light does not reach the toner sensor, “H” is displayed on

the Operator Panel.

5

. If

the Operator Panel display toggles between “H” <-> “L” as a paper

is flipped in front of the toner sensor, it indicates that the toner sensor

and the related system of the printer are working normally.

Act

ion to be taken at NG

• Clean surface of the toner sensor to remove the stains due to residual

toner and paper dust.

• Che

ck the connection condition of the FFC cable at the PU main PCB

(PU) and at the toner sensor PCB (PRZ).

• Per

form the operation check again. If the situation is not improved

and remains unchanged, replace the PU main PCB (PU) or the toner

sensor PCB (PRZ).

(2) H

ow to check operation of the toner sensor at the toner cartridge (TC)

side

1. To the position where the toner sensor is confirmed to be operating

normally in the printer itself by the above paragraph (1), install the

TC and the ID unit to check operations by observing display on the

Operator Panel.

2. If the ID unit works normally, the display on the Operator Panel will

toggle between “H” <-> “L” in synchronism with movement of the silver

reflector plate that is located on the side of the ID.

A

ct

ion to be taken at NG

• Check operation condition of the respective ID motors by using the

Motor & Clutch Test of the self-diagnostic mode.

• Cle

an surface of the silver reflector plate on the side of ID to remove

stains. (Stain due to toner or paper dust).

• Rep

lace the TC of different color and the ID unit as a pair.

If a satisfactory operation is attained by using a pair of TC of different

color and the ID unit, replace the TC or replace the ID unit.

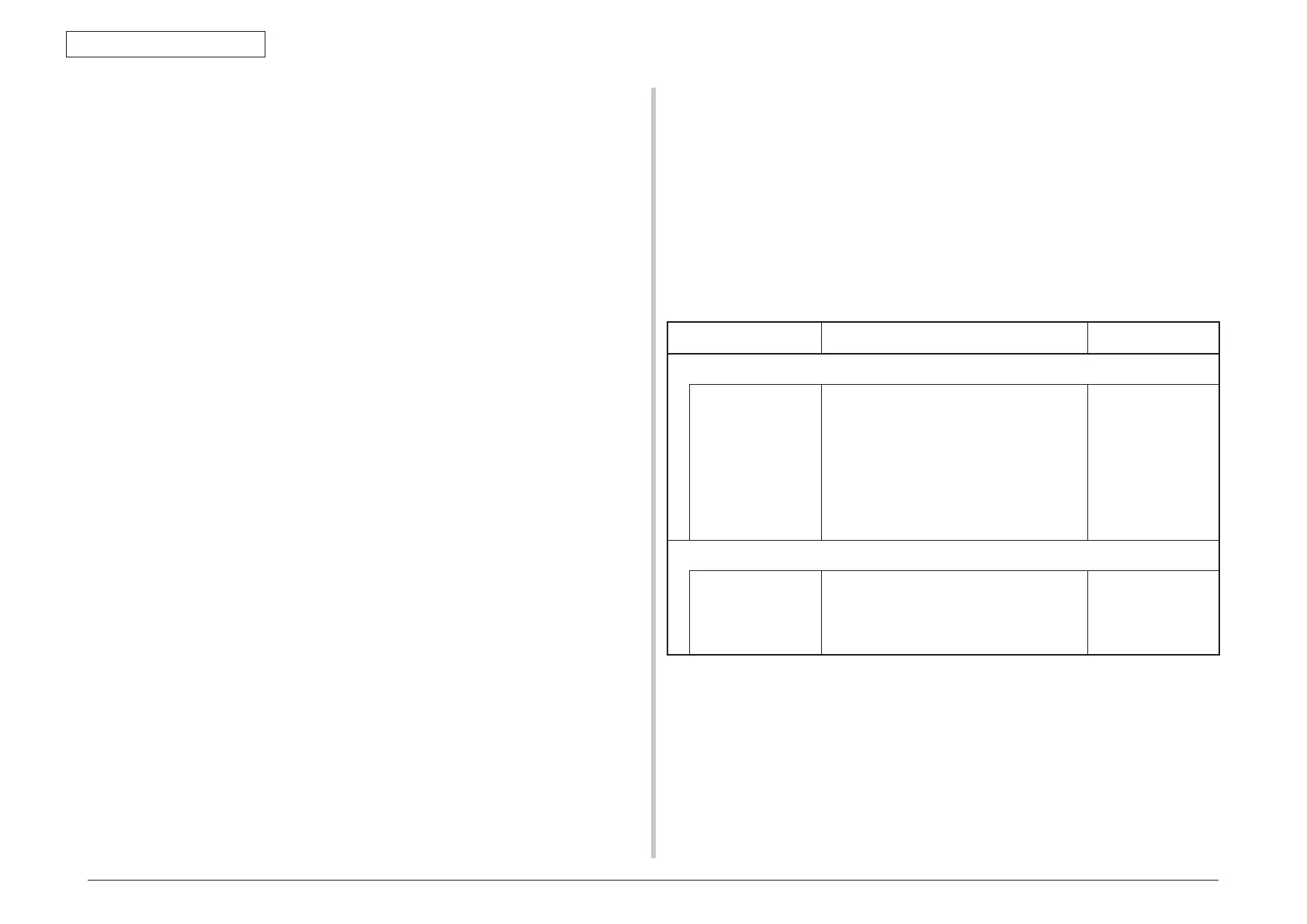

(16-3) Error caused by the def

ective mechanism

Check item Check work

Action to be taken at NG

(16-3-1) Mechanical load applied to the ID unit

ID unit Check if a heavy mechanical load is being

applied to the ID unit due to breakage of

the waster toner belt, or not.

Replace the ID unit.

If any attempt of

using new ID unit

as a trial is going to

be made, be sure

to use the System

Maintenance Menu

FUSE KEEP MODE.

(16-3-2) Motor operating condition

ID motor Confir

m that the respective ID motors work

normally or not by using the Motor & Clutch

Test of the self-diagnostic mode.

Check if any extra load exists or not.

Replace the PU

PCB or ID motor

Loading...

Loading...