43967002TH Rev.1

34 /

Oki Data CONFIDENTIAL

2. Theory of Operation

2.2 Print process

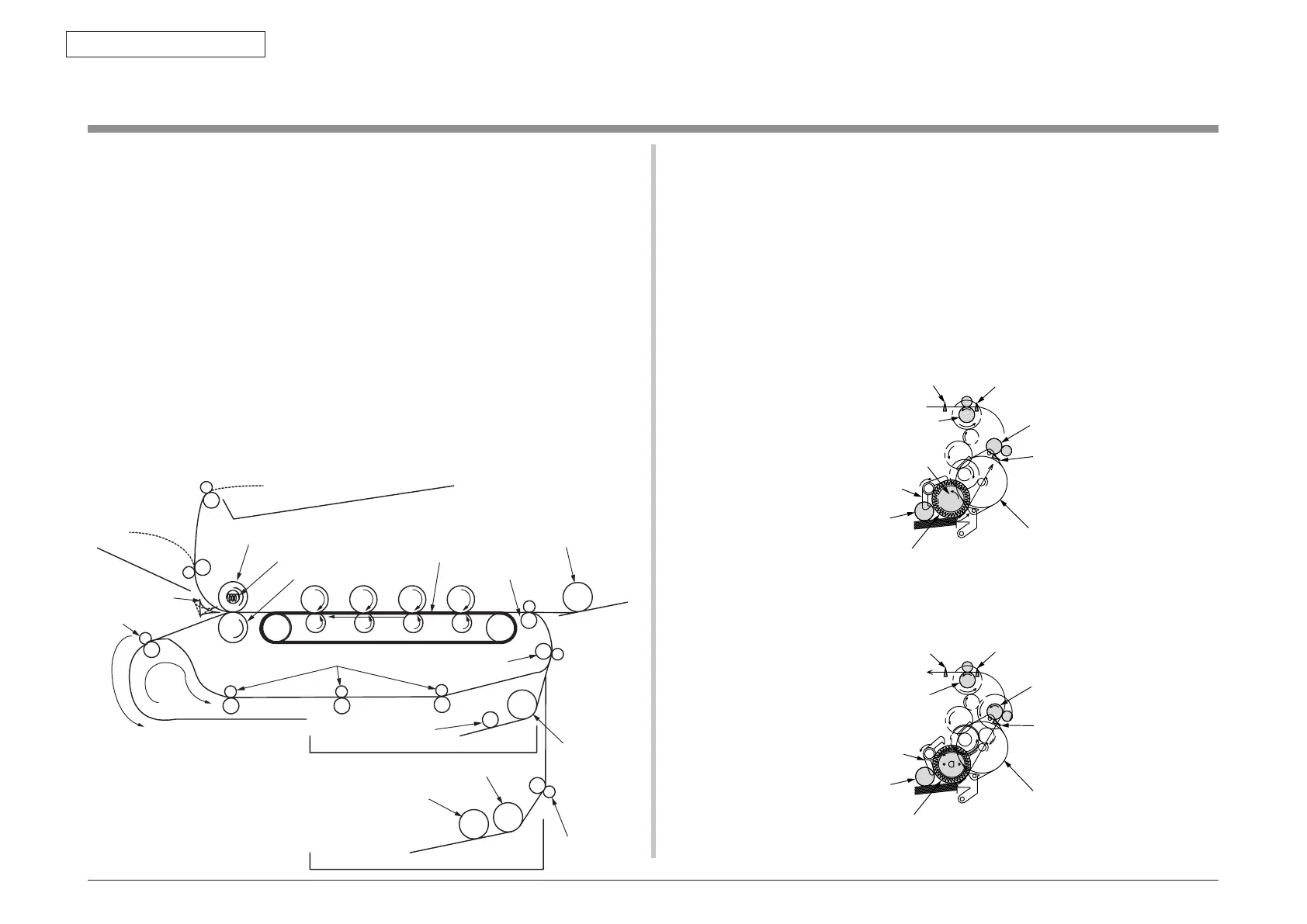

The paper that is fed from the tray 1 or tray 2 or tray 3 is transported by the feed paper roller, the

regist roller L and the transport roller. When paper is fed from MTP, paper is transported by the

MPT feed paper roller and the regist roller U. The paper that is transported on the belt passes

through the electro-photographic process of KYMC and the non-diffused toner image is created

on the paper. When paper passes through the fuser unit, the toner image is fused by heat and

pressure. After the toner image is fused, the paper is unloaded to the face-up stacker or the

face-down stacker depending on the unloading method selected by open/close of the face-up

stacker.

Operation during the one-sided print is described above. Operation during the both-sided print

is described below The paper that has passed through the fuser unit after the rear-side print

is completed first, is transported to the Duplex unit by the separator DUP. The paper that has

entered in to the paper inverting transport path is then transported to the inside of the Duplex

unit from the paper inverting transport path by the inverting movement of the inverting roller. The

paper that has passed through the Duplex unit by the transport roller of the transport path inside

the Duplex unit, is supplied from the feed paper path of the Duplex unit so that the paper enters

the same paper transport path as the feed paper route from the trays. The remaining operations

are the same as those of the one-sided print using the paper supplied from the trays.

Face-down stacker

Face up stacker

MPT

Paper inverting transport path

Sub roller

Feed roller

Sub roller

Transport roller

Feed roller

Regist roller L

Regist roller U

MPT feed paper roller

Transport roller

Transport roller

Inverting roller

Separator DUP

Heat roller

Backup roller

Halogen lamp

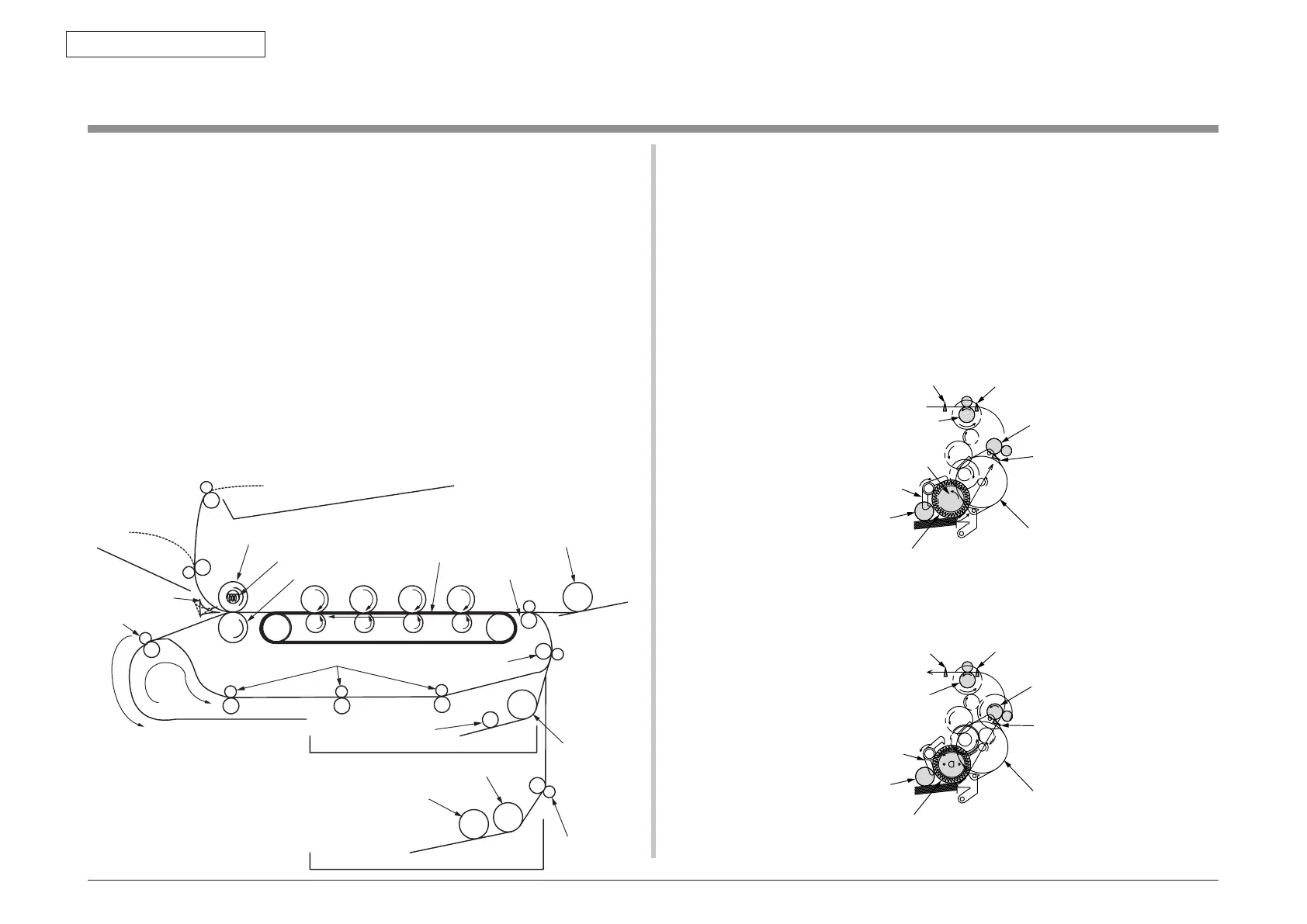

(1) Feed paper from the 1st tray

1. When the regist motor rotates (in counter-clockwise direction) while the

solenoid is activated to the ON state as shown in Fig. 2-1, the paper is

transported until the IN1 sensor is turned ON. (When the solenoid is turned

ON, the feed paper roller is driven.)

2

. W

hen the paper turns ON the IN1 sensor, the specified amount of paper is

transported so that the paper is pressed against the regist roller L. (Thus,

paper skew is corrected)

3. A

s shown in Fig. 2-2, the solenoid is turned OFF so that paper is transported

by the regist roller L. (When the solenoid is turned OFF, the regist roller L is

driven.)

Regist roller U

(drive)

Regist roller U

(drive)

Hopping roller

(drive)

Hopping roller

(stop)

Paper

Paper

Sub roller

(drive)

Sub roller

(stop)

Regist motor

(Rotates in counter-clockwise direction.)

Regist motor

(Rotates in counter-clockwise direction.)

Regist roller L

(stop)

Regist roller L

(drive)

WR sensor

WR sensor

Solenoid lever

(Solenoid ON)

Solenoid lever

(Solenoid OFF)

Hopping gear Assy

IN2 sensor

IN2 sensor

IN1 sensor

IN1 sensor

Fig. 2-1

Fig. 2-2

Loading...

Loading...