Section 05 ELECTRICAL SYSTEM

Subsection 02 (WIRING HARNESS AND CONNECTORS)

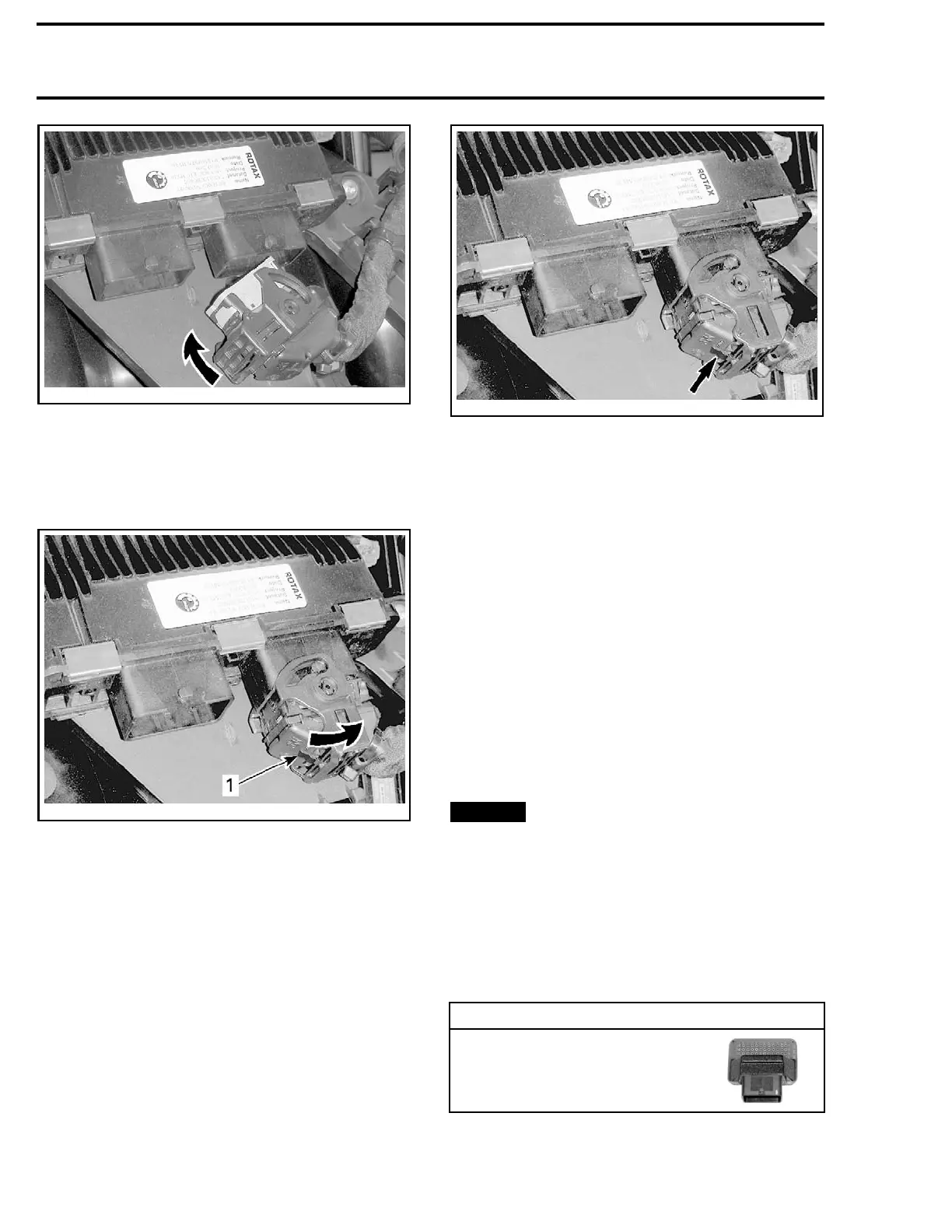

smr2009-045-013_b

CONNECTOR LOCKING CAM IN RELEASE POSITION

2. Insert connector on ECM.

3. As you push the connector onto the ECM, ro-

tate the connector locking cam until it snaps

locked.

smr2009-045-011_b

1. Locked

here

4. Ensure the locking tab is fully out.

smr2009-045-011_a

LOCKING TAB FULLY OUT

Inspecting the Connector

Before replacing an ECM, always check electrical

connections.

1. Ensure connector locking mechanism is func-

tioning properly.

2. Ensure all wire terminals (pins) are properly

locked in the connector.

3. Ensure they are very tight, make good contact

with the p ins in the ECM.

4. Ensure the pins in the harness connector

and the ECM connector are clean, shiny and

corrosion-free.

5. Check wiring harness for signs of scoring.

NOTE: A “defective ECM module” could possi-

bly be repaired simply by disconnecting and recon-

necting it.

NOTICE

Do not apply any lubricant product

to the pins of the ECM connector.

Probing the Connector

The most recommended and safest method to

probe the MOLEX (ECM) connector terminals

is to use the ECM adapter tool. This tool will

prevent deforming or enlarging of the terminals,

which would lead to bad ECM terminal contact

creating intermittent or permanent problems.

REQUIRED TOOL

ECM ADAPTER TOOL (P/N 529

036 166)

1. Disconnect the ECM connector to be probed,

and reconnect it on the ECM adapter.

114 219100963-012

Loading...

Loading...