Scope and Multimeter Operations General Reference (Testing Strategies)

147

9.17.3 Troubleshooting Signals

When capturing signals, you may occasionally encounter problems with the way

the signal initially displays. Noise, hash and fuzz are some of the terms used to

describe unwanted signals displaying in or on the signal you are trying to capture,

basically making the signal unclear. The following tips are intended to provide some

basic guidance, to help resolve these types of issues if encountered.

• Make sure you have the correct test leads connected to the applicable test

point(s) and test lead jacks on the diagnostic tool.

• Ensure the signal and ground connections are clean and secure, at the test

points and diagnostic tool.

• Ensure the polarity of the test leads connections are correct.

• If using stackable connectors, try to isolate or only connect the leads being used

to capture the signal.

• Make sure the ground lead is providing a direct ground from the circuit to the

diagnostic tool test lead jack.

• Isolate the test leads from other components, leads, or systems that may induce

unwanted noise into the signal being tested (e.g. electric motors, secondary

ignition components, relays, alternators, etc.)

• Use the shortest test leads possible.

• Try different test leads, to verify the issue. Use the recommended snap-on leads

or probes available for the diagnostic tool or equivalent. Shielded test leads are

recommended.

• Check the test lead or probes for damage.

• Enable or disable channel controls also to help try and clean the signal:

– Peak Detect Icon—maximizes sampling rate, but may pickup unwanted

noise

– Filter Icon—removes signal noise or interference

– Invert Icon—switches signal polarity

– Coupling AC Icon—blocks the DC portion of signal

– Threshold Auto/Manual (GMM Only)—provides a more accurate

measurement on select GMM tests where noise is present

– Scale (Vertical / Y-axis)—adjusts vertical scale. Using a higher setting may

provide a cleaner signal in some situations.

For signals that do not display or display off the screen, erratic, compressed etc.:

Use a trigger to help stabilize the signal. Try and set the trigger at the mid-point of

the signal, and then adjust as needed from there. See Triggers on page 122.

If the signal wraps off the top and bottom of the display, try and readjust the vertical

scale to a higher setting, to bring the signal into the viewable display area. See

Scale (Vertical / Y-axis).

If the signal cycles are compressed (close to each other), try and readjust the

sweep scale (horizontal scale) to a lower setting to display less cycles. Try a higher

setting if the cycles are spread too far across the screen and seem flat. See Sweep

Scale (X-axis).

Move the zero baseline marker to move the zero baseline of the signal vertically on

the screen to the desired position. See Zero Baseline Adjustment on page 120.

• Check calibration of test leads or probe(s) if applicable. See Test Lead / Probe

Calibration on page 106.

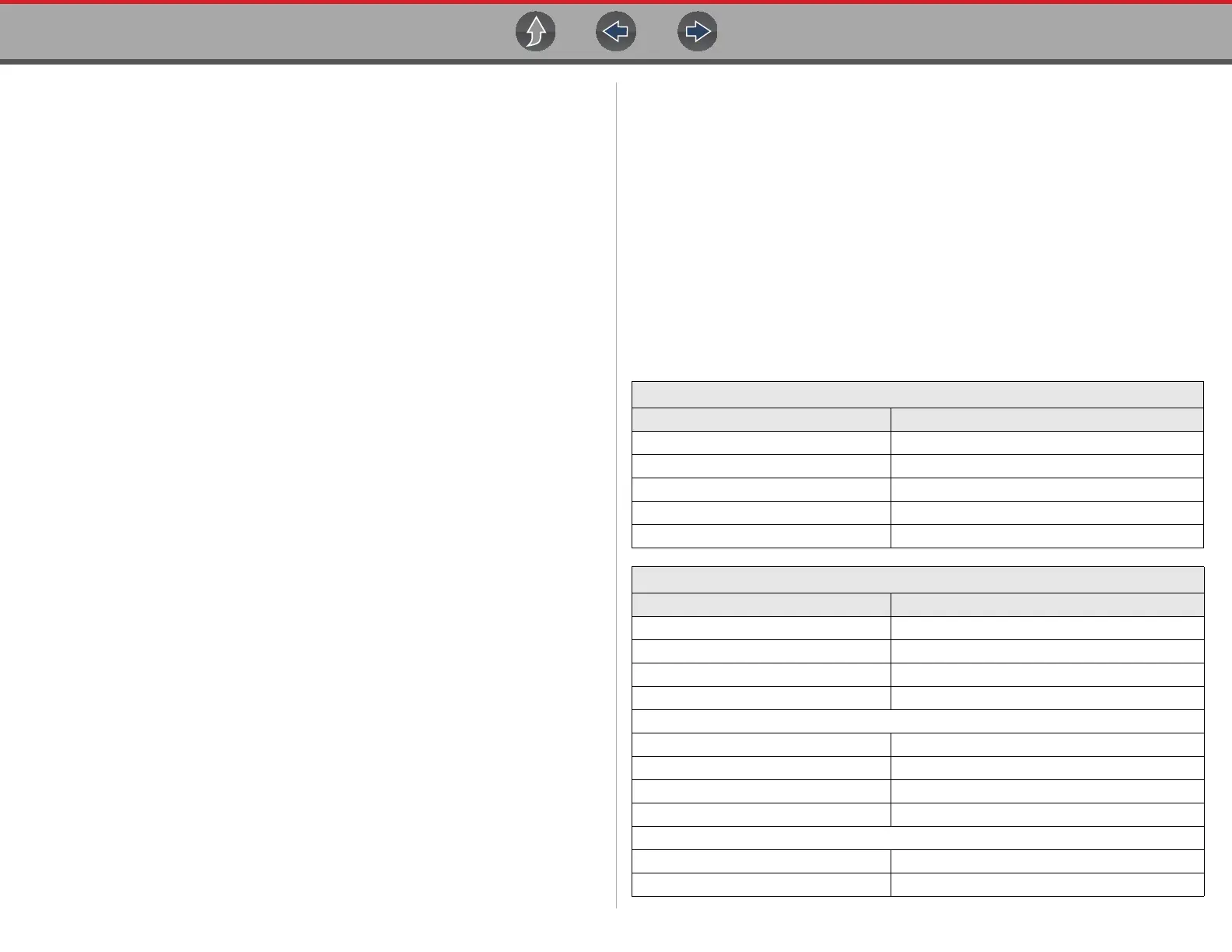

9.17.4 Units of Measurement / Conversions

Base Units

(Symbol) / Unit Prefix Typical Expressions

(µ) micro 0.000001 or 10

-6

or 1/1,000,000

(m) milli 0.001 or 10

-3

or 1/1,000

(c) centi 0.01 or 10

-2

or 1/100

(k) kilo 10

3

or 1,000

(M) mega 10

6

or 1,000,000

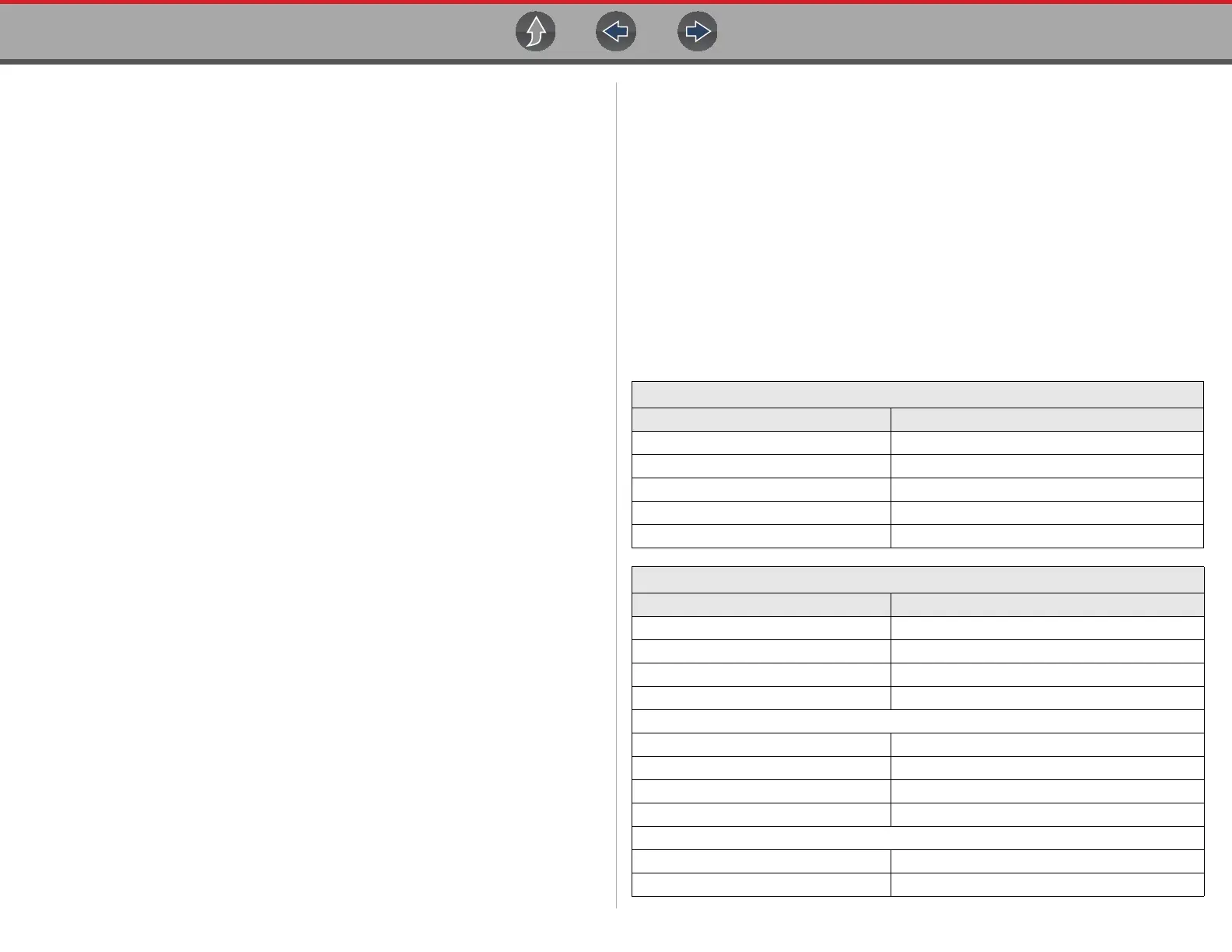

Electrical Units

(Symbol) / Description Equivalents

(V) Voltage V = I × R

(I) Current I = V ÷ R

(R) or (Ω) Resistance R = V ÷ I

(Hz) Frequency ƒ(freq.) = 1 ÷ T(time) or 1 cycle per second

Voltage

(µV) microvolt 1 µV = 0.000001 V

(mV) millivolt 1 mV = 0.001 V

(V) volt 1 V = 1000 mV

(kV) kilovolt 1kV = 1,000 Volts.

Ohms

(mΩ) milliohm 1 mΩ = 0.001 ohms

(Ω) ohm 1 Ω = 1000 mΩ

Loading...

Loading...