Adjustment(continued)

6.Formachineserialnumbersabove316000200adjustthewingdeckswitches

asfollows(Figure190):

A.Raisethewingdecktoa12degreeangleandsafelysupportthedeckto

preventitfromloweringduringtheadjustmentprocedure.

B.Thecenteroftheswitchsensingeyeshouldbe6.3mm(0.25in)above

theupperedgeofthesensingplate.Loosenthesensingplatemounting

fastenerstoadjusttheplateasneeded.

C.Loosenthelocknutssecuringtheswitchtotheswitchbracketandset

thepositionswitchsothecorrectclearanceexistsbetweenthetarget

eyeandthesensingplate.Tightenthepositionswitchlocknutsfrom19

to21N·m(14to16ft−lb).

TractionPedalNeutralAdjustment

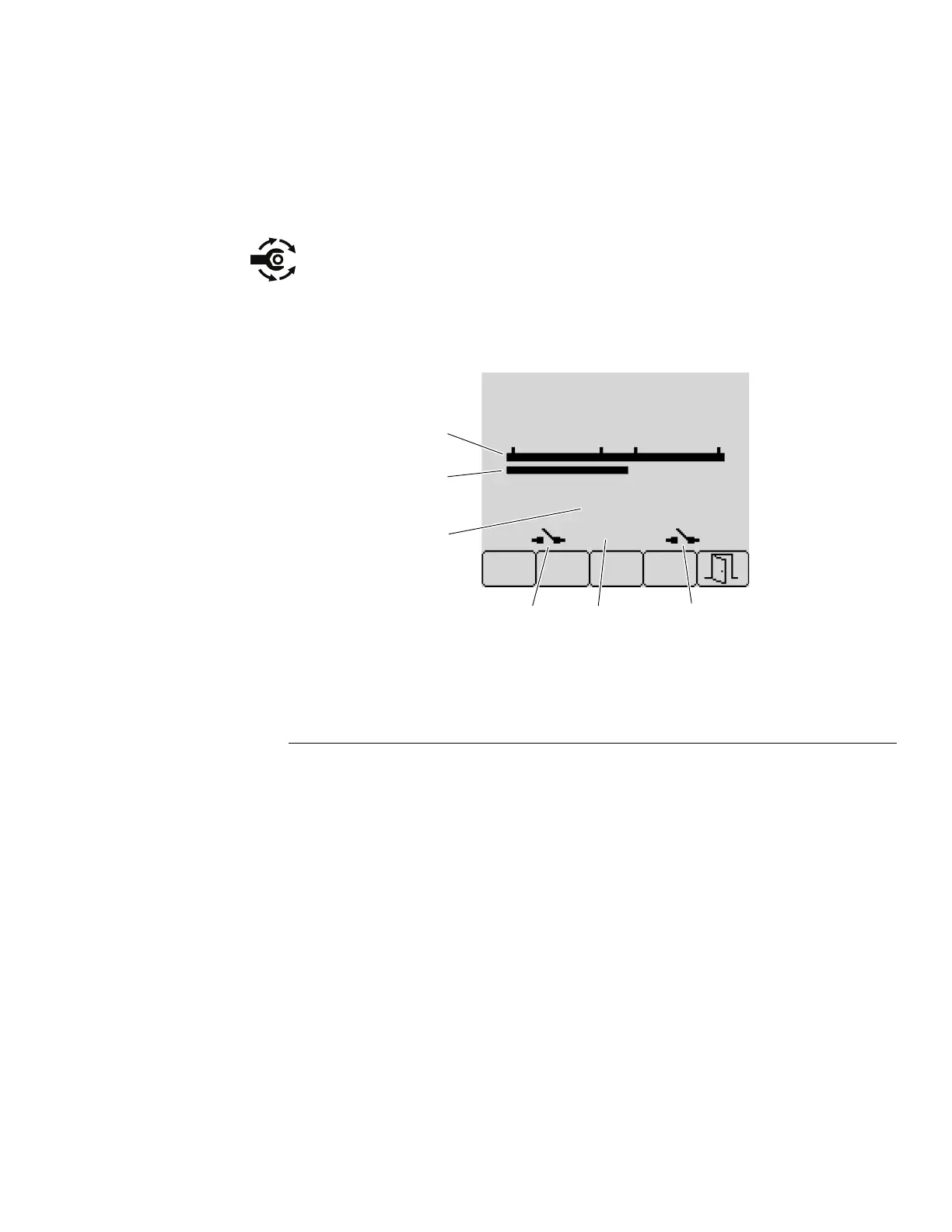

R NR NF F

2.23 V

FNRN

2.25 V 2.33 V2.18 V

CALIBRATED

1

2

3

5

4

6

g288434

Figure191

1.Bargraph4.Forwardswitchicon

2.Positionindicatorbar5.Neutralvoltage

3.Reverseswitchicon6.Midpointvoltage

Thetractionpedalincludesaneutralassemblythatisusedtoadjustthetraction

pedalneutralposition.Tractionpedaladjustmentmaybenecessarytoensure

thetractionpedalmovementprovidesthecorrectfullreverseandfullforward

positionsforthetractionpedalpositionsensor.UsetheInfoCenterdisplayto

checktractionpedaladjustmentusingthefollowingprocedure:

1.Parkmachineonalevelsurface,lowercuttingdecksandstopengine.

2.TurnkeyswitchtoRUNbutdonotstartengine.

3.UsetheInfoCenterDisplaytoaccesstheTractionPedalscreen(see

InfoCenterDisplay−SERVICE(page6–14)Screens).

4.Pressbutton2fromtheTractionPedalscreentoviewtheNeutralscreen

(Figure191).

Groundsmaster

®

5900&5910

Page6–49

ElectricalSystem:Adjustments

16227SLRevB

Loading...

Loading...