TractionPedalNeutralAdjustment(continued)

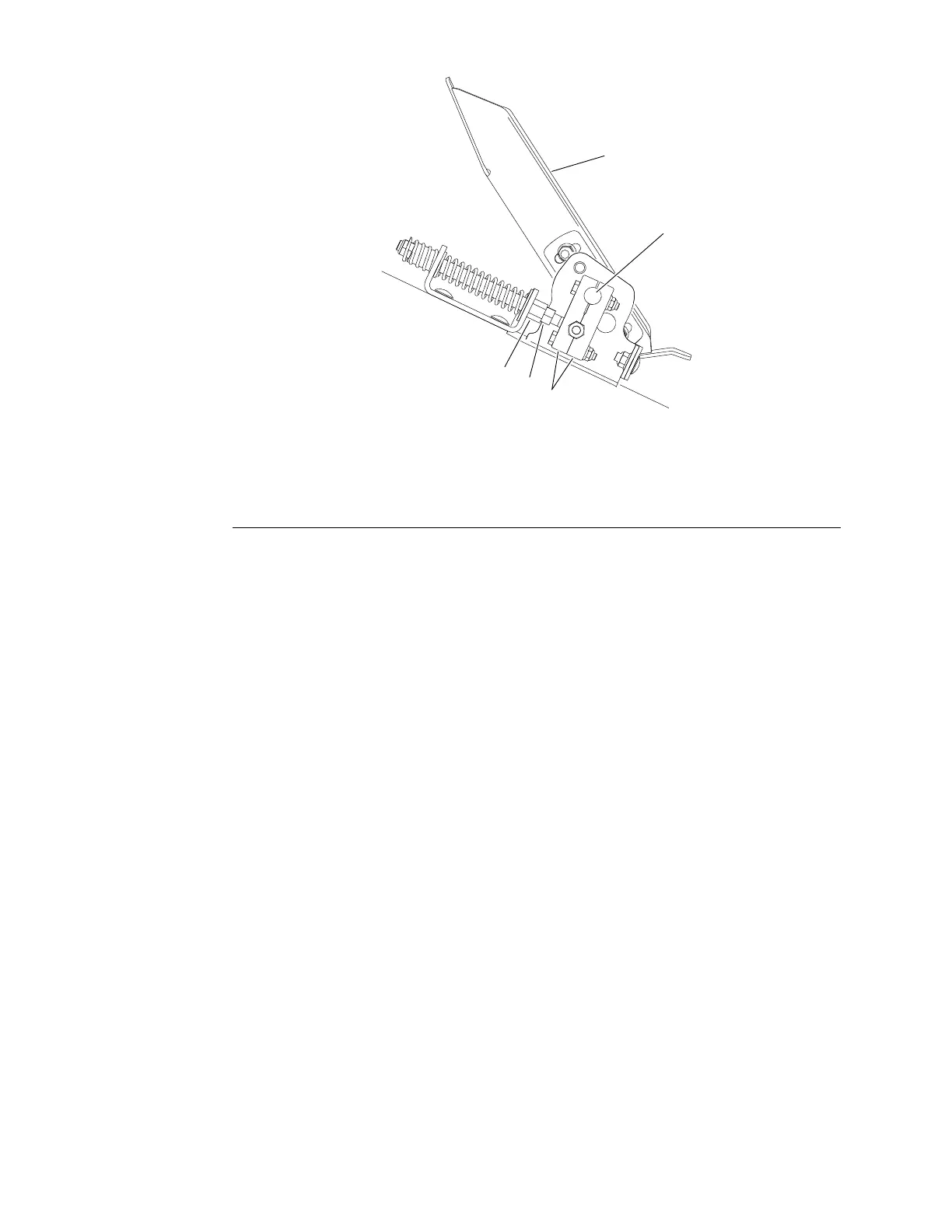

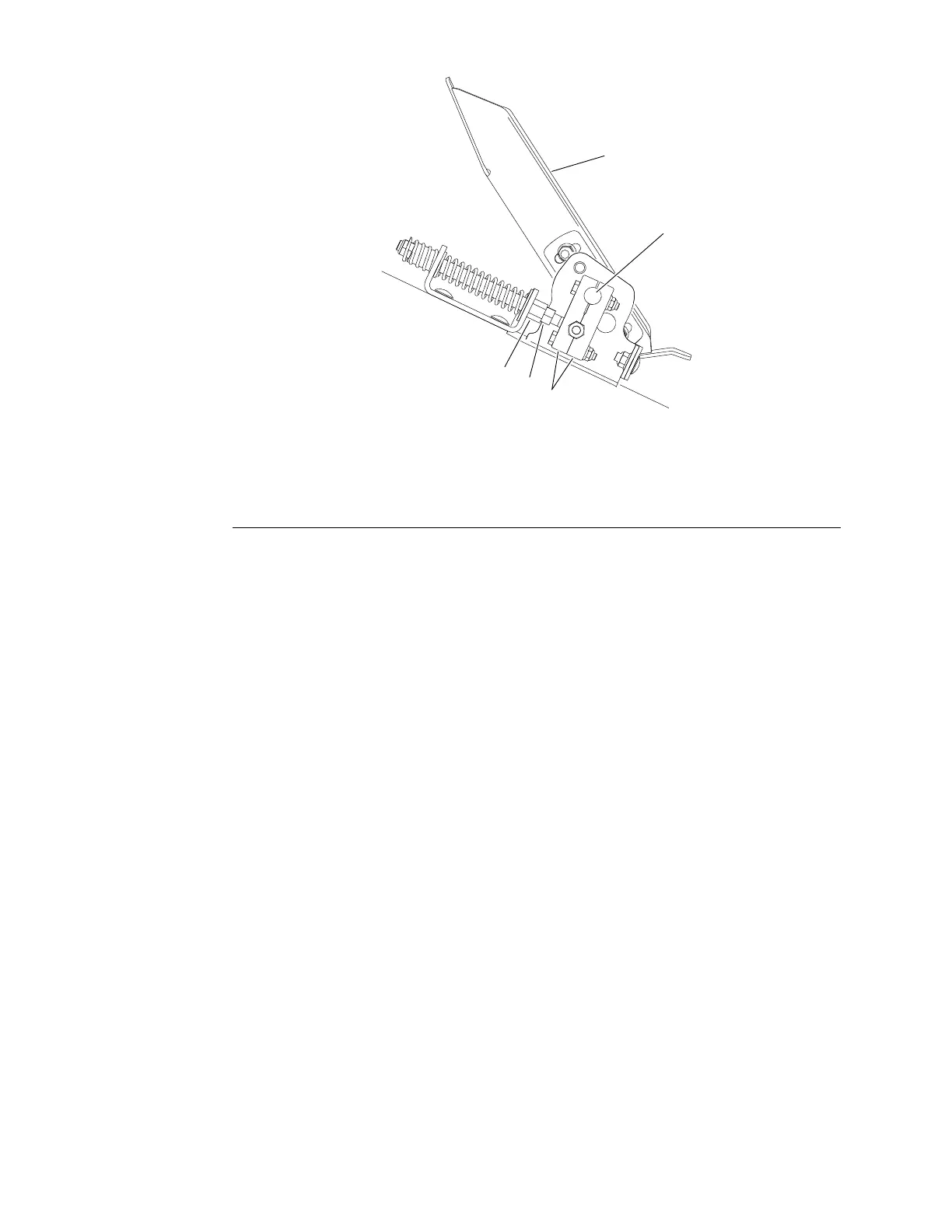

g288435

Figure192

1.Tractionpedal4.Locknut

2.Tractionpedalshaft5.Springshaft

3.Clampblocks

5.Onthebargraphinthescreen,thepositionindicatorbarshouldbebetween

NRandtheNF .Also,thereverseswitchandforwardswitchiconsshould

bothbeopen.

Toadjustthepositionindicatorbarlocation:

A.Removescrewssecuringsteeringcoverandmovesteeringcoverup

steeringcolumntoaccesstractionpedalassembly(seeTractionPedal

(page7–37)).

B.Loosenhexnutthatsecuresneutralspringadjustment(Figure192).

C.Slowlyrotatethespringshaftwhilewatchingtheswitchicons(Figure

192).Whenoneoftheswitchiconsclose,stoprotatingandmarkthe

shaftposition.Thenslowlyrotatetheshaftintheoppositedirectionuntil

thesecondswitchiconclosesandmarktheshaftposition.

D.Slowlyrotatethespringshafttothemid−pointofthetwoshaftpositions.

Tightenthehexnuttosecuretheadjustment.Atthissetting,theposition

indicatorbarshouldbebetweentheNRandtheNF.Also,theneutral

voltagevalueshouldbewithin0.02Vofthemidpointvoltage.

Note:Whenadjustingtractionpedal,voltagevaluesshouldbesimilarto

valuesshown(Figure191).

E.Installsteeringcover.

6.Afteradjustingthetractionpedalforneutral,andbeforereturningthe

machinetoregularservice,calibratetractionpedalpositionsensor(see

TractionPedalPositionSensorCalibration(page6–51)).

ElectricalSystem:Adjustments

Page6–50

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...