4.7 Auto-Tuning

114 YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual

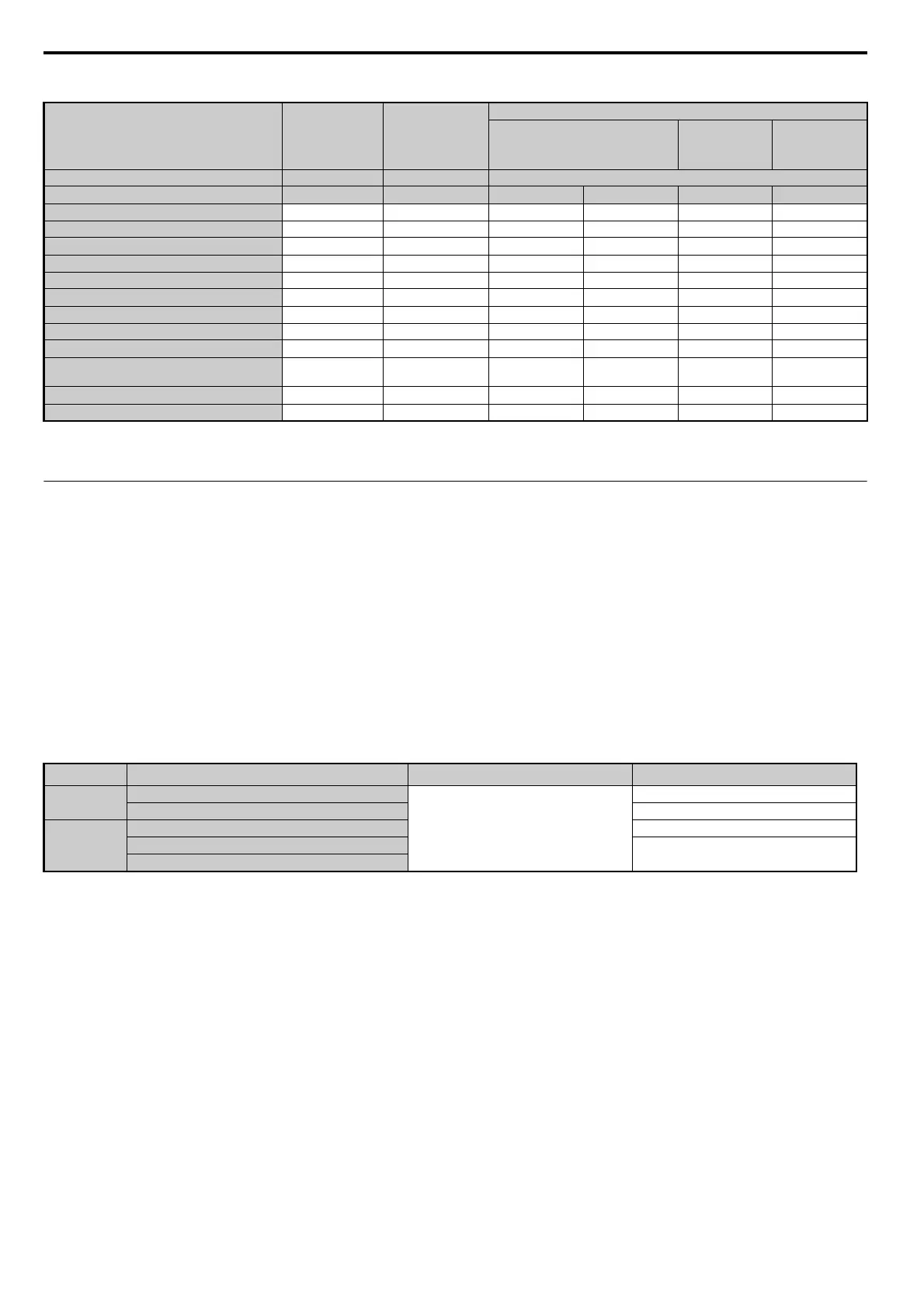

Table 4.16 Auto-Tuning Input Data

◆ Before Auto-Tuning the Drive

Check the items below before Auto-Tuning the drive.

■

Basic Auto-Tuning Preparations

• Auto-Tuning requires the user to input data from the motor nameplate or motor test report. Make sure this data is

available before Auto-Tuning the drive.

• For best performance, the drive input supply voltage must be greater than the motor rated voltage.

Note: Better performance is possible when using a motor with a base voltage that is 20 V (40 V for 400 V class models) lower than the

input supply voltage.

• To cancel Auto-Tuning, press the STOP key on the digital operator.

• When using a motor contactor, make sure it is closed throughout the Auto-Tuning process.

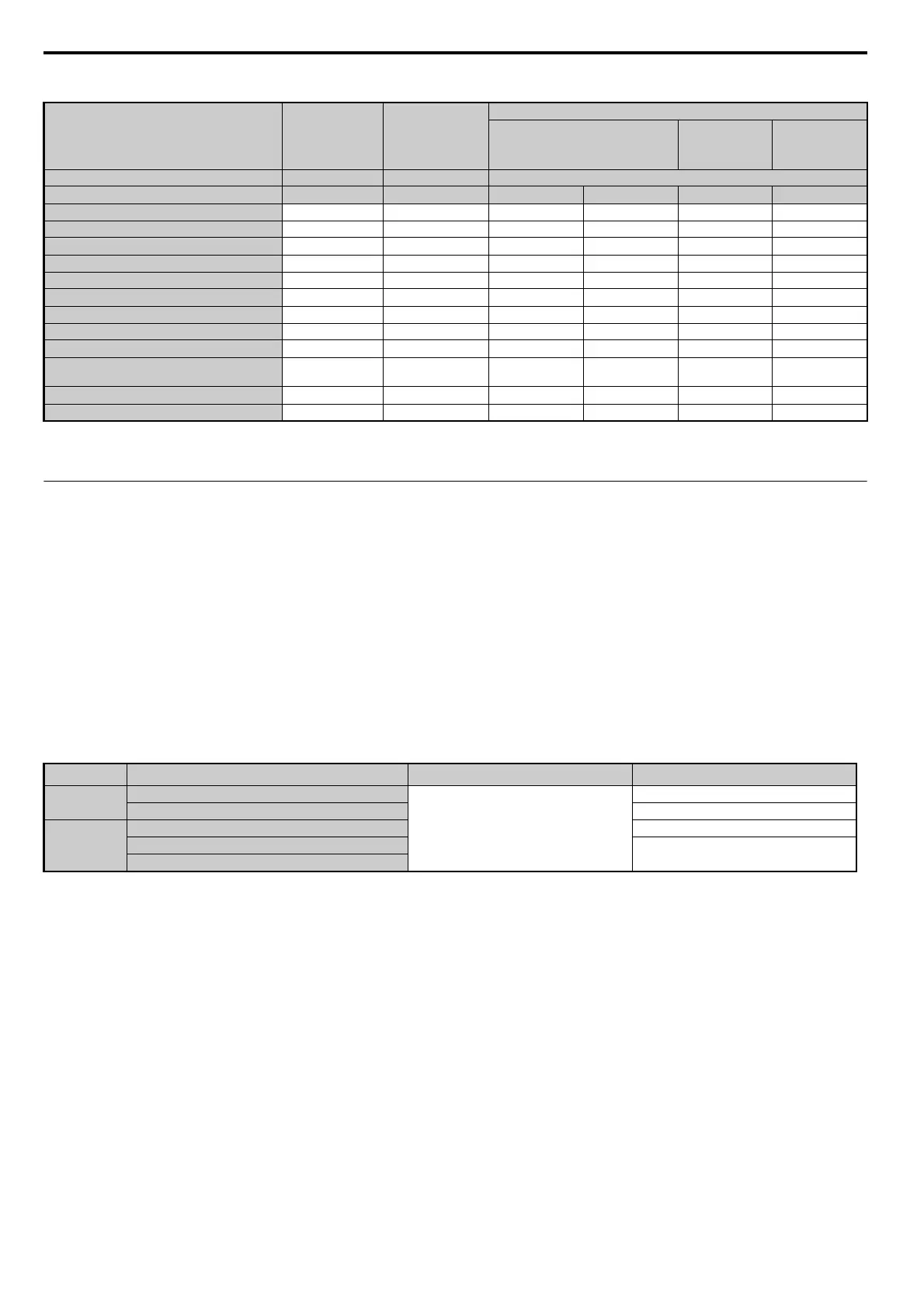

• Table 4.17 describes digital input and output terminal operation while Auto-Tuning is executed.

Table 4.17 Digital Input and Output Operation During Auto-Tuning

■ Notes on Rotational Auto-Tuning

• To achieve optimal performance from Rotational Auto-Tuning, the load should be decoupled from the motor.

Rotational Auto-Tuning is best suited for applications requiring high performance over a wide speed range.

• If motor and load can not be decoupled, reduce the load so that it is no greater than 30% of the rated load. Performing

Rotational Auto-Tuning with a higher load will set motor parameters incorrectly, and can cause irregular motor

rotation.

• Ensure the motor-mounted brake is fully released if installed.

• Connected machinery should be allowed to rotate the motor.

■

Notes on Stationary Auto-Tuning

Stationary Auto-Tuning modes analyze motor characteristics by injecting current into the motor for about one minute.

WARNING! Electrical Shock Hazard. When executing stationary Auto-Tuning, the motor does not rotate, however, power is applied.

Do not touch the motor until Auto-Tuning is completed. Failure to comply may result in injury from electrical shock.

WARNING! Sudden Movement Hazard. If installed, do not release the mechanical brake during stationary Auto-Tuning. Inadvertent

brake release may cause damage to equipment or injury to personnel. Ensure that the mechanical brake release circuit is not

controlled by the drive multi-function digital outputs.

Input Value

<1> Only parameter T2-13 or T2-14 has to be input. Select one and leave the other empty.

<2> Depends on T2-13 setting.

Input Parameter Unit

Tuning Type (T2-01)

0

Motor Parameter Settings

1

Stationary

2

Stationary

Stator

Resistance

Control Mode A1-02 – 5

Motor Code T2-02 – FFFFH FFFFH – –

Motor Type T2-03 – N/A N/A YES N/A

Motor rated power T2-04 kW N/A YES YES N/A

Motor rated voltage T2-05 Vac N/A YES YES N/A

Motor rated current T2-06 A N/A YES YES YES

Motor rated frequency T2-07 Hz N/A YES YES N/A

Number of motor poles T2-08 – N/A YES YES N/A

Stator 1 Phase resistance T2-10 Ω YES YES N/A N/A

d-axis inductance T2-11 mH YES YES N/A N/A

q-axis inductance T2-12 mH YES YES N/A N/A

Induced Voltage constant Unit

Selection

<1>

T2-13 mVs/rad (el.) YES YES N/A N/A

Voltage constant <2> T2-14 mVmin (mech.) YES YES N/A N/A

Tuning pull-in current T2-15 A N/A N/A YES N/A

Motor Type Auto-Tuning Type Digital Input Digital Output

IM Motor

Stationary Auto-Tuning for Line-to-Line Resistance

Digital input functions are disabled.

Maintains the status at the start of Auto-Tuning

Rotational Auto-Tuning for V/f Control Functions the same as during normal operation

PM Motor

PM Motor Parameter Settings Digital output functions are disabled.

PM Stationary Auto-Tuning

Maintains the status at the start of Auto-Tuning

PM Stationary Auto-Tuning for Stator Resistance

SIEP_C710616_35.book 114 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...