6.2 Motor Performance Fine-Tuning

258 YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual

6.2 Motor Performance Fine-Tuning

This section offers helpful information for counteracting oscillation, hunting, or other problems that occur while

performing a trial run. Refer to the section below that corresponds to the motor control method used.

Note: This section describes parameters that are commonly edited and may be set incorrectly. Consult Yaskawa for more information

on detailed settings and fine-tuning the drive.

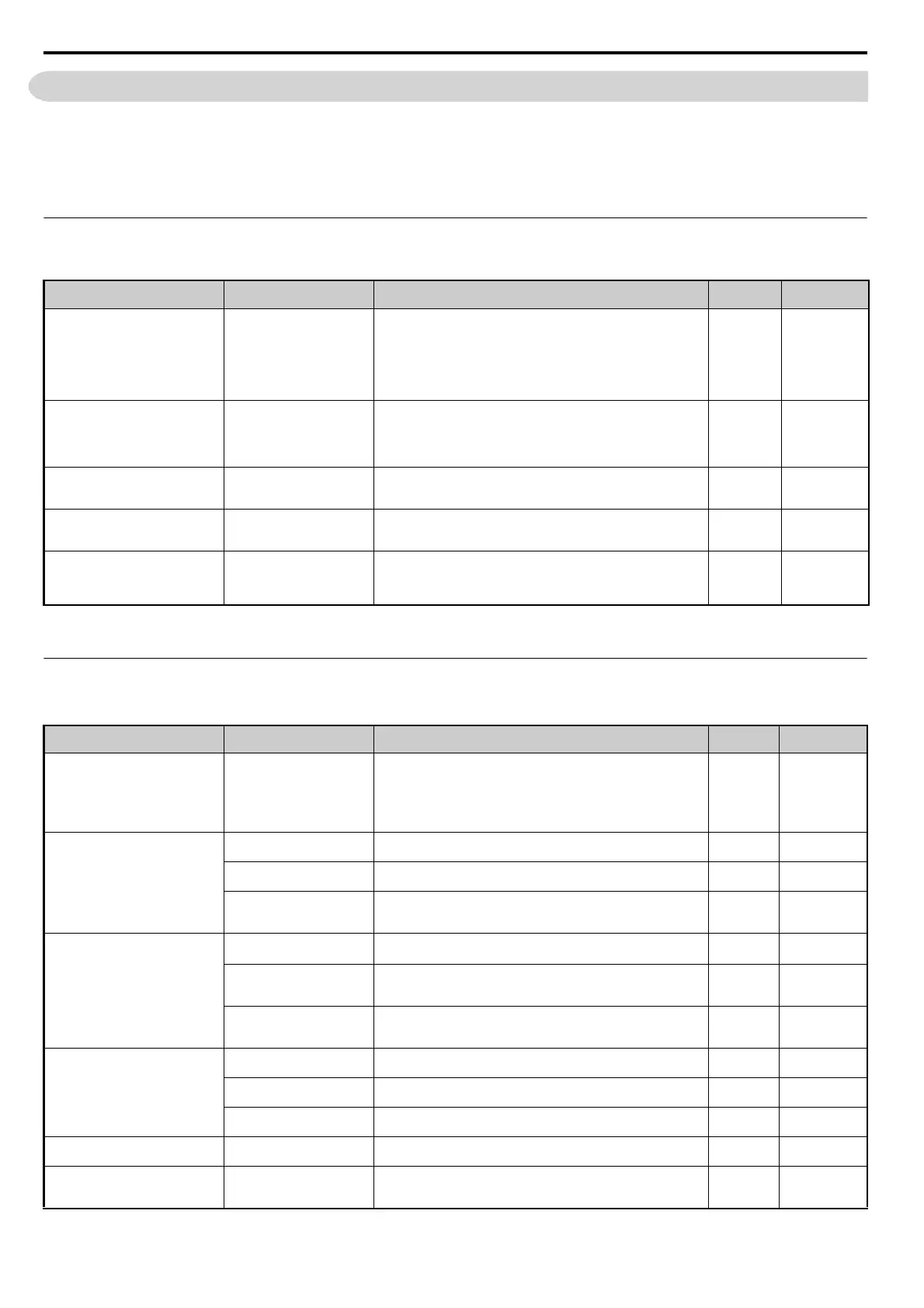

◆ Fine-Tuning V/f Control

Table 6.1 Parameters for Fine-Tuning Performance in V/f

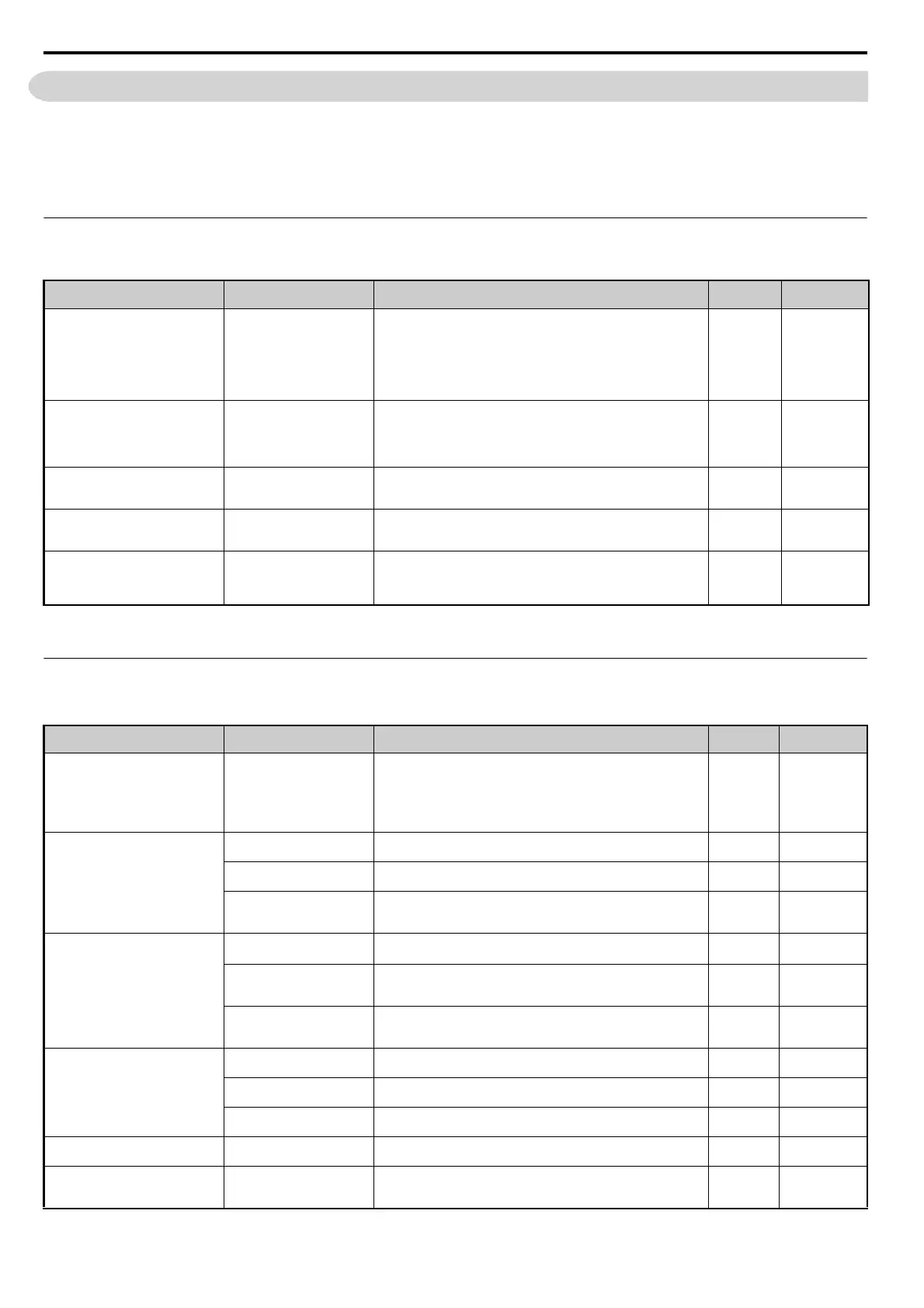

◆ Fine-Tuning Open Loop Vector Control for PM Motors

Table 6.2 Parameters for Fine-Tuning Performance in OLV/PM

Problem

<1> Default setting value is dependent on parameter A1-02, Control Method Selection, and o2-04, Drive Model Selection.

<2> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03.

Parameter No. Corrective Action Default

Suggested

Setting

Motor hunting and oscillation at speeds

between 10 and 40 Hz

Hunting Prevention Gain

(n1-02)

• If insufficient motor torque relative to the size of the load causes hunting,

reduce the setting.

• When motor hunting and oscillation occur with a light load, increase the

setting.

• Lower this setting if hunting occurs when using a motor with a relatively

low inductance, such as a high-frequency motor or a motor with a larger

frame size.

1.00 0.10 to 2.00

• Motor noise

• Motor hunting and oscillation at

speeds up to 40 Hz

Carrier Frequency Selection

(C6-02)

• If the motor noise is too loud, increase the carrier frequency.

• When motor hunting and oscillation occur at speeds up to 40 Hz, lower

the carrier frequency.

• The default setting for the carrier frequency depends on the drive

capacity (o2-04).

1 (2 kHz) 1 to max. setting

• Poor torque or speed response

• Motor hunting and oscillation

Torque Compensation Primary

Delay Time

(C4-02)

• If motor torque and speed response are too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

200 ms

<1> 100 to 1000 ms

• Poor motor torque at speeds below 10

Hz

• Motor hunting and oscillation

Torque Compensation Gain

(C4-01)

• If motor torque is insufficient at speeds below 10 Hz, increase the setting.

• If motor hunting and oscillation with a relatively light load, decrease the

setting.

1.00 0.50 to 1.50

• Poor motor torque at low speeds

• Motor instability at motor start

Mid Output Voltage A (E1-08)

Minimum Output Voltage

(E1-10)

• If torque is insufficient at speeds below 10 Hz, increase the setting.

• If motor instability occurs at motor start, decrease the setting.

Note: The recommended setting value is for 200 V class drives. Double this

value when using a 400 V class drive.

E1-08: 15.0 V

E1-10: 9.0 V

<2>

Default setting

±5 V

Problem Parameter No. Corrective Action Default

Suggested

Setting

Motor performance not as desired

Motor parameters

(E1-, E5-)

• Check the settings for base and maximum frequency in the E1-

parameters

• Check E5- parameters and make sure all motor data has been set

correctly. Be careful not to enter line to line data where single-phase data

is required, and vice versa.

• Perform Auto-Tuning.

––

Poor motor torque and speed response

Load Inertia Ratio (n8-55) Adjust parameter n8-55 to meet the load inertia ratio of the machine. 0

Close to the actual

load inertia ratio

Speed Feedback Detection Gain

(n8-45)

Increase the speed feedback detection gain (n8-45). 0.8

Increase in

increments of 0.05

Torque Compensation (C4-01)

Enable torque compensation.

Note: Setting this value too high can cause overcompensation and motor

oscillation.

01

Oscillation at start or the motor stalls

Pull-In Current during Accel/

Decel (n8-51)

Increase the pull-in current set in n8-51 50%

Increase in steps

of 5%

DC Injection Braking Current

(b2-02), DC Injection Time at

Start (b2-03)

Use DC Injection Braking at start to align the rotor. Be aware that this

operation can cause a short reverse rotation at start.

b2-02 = 50%

b2-03 = 0.0 s

b2-03 = 0.5 s

Increase b2-02 if

needed

Load Inertia Ratio (n8-55)

Increase the load inertia ratio.

Note: Setting this value too high can cause overcompensation and motor

oscillation.

0

Close to the actual

load inertia ratio

Stalling or oscillation occur when load

is applied during constant speed

Pull-In Current Compensation

Time Constant (n8-47)

Decrease n8-47 if hunting occurs during constant speed 5.0 s

Reduce in

increments of 0.2 s

Pull-In Current (n8-48) Increase the pull-in current in n8-48. 30%

Increase in

increments of 5%

Load Inertia Ratio (n8-55) Increase the load inertia ratio. 0

Close to the actual

load inertia ratio

Hunting or oscillation occur

Speed feedback Detection Gain

(n8-45)

Decrease the speed feedback detection gain in n8-45. 0.8

Increase in

increments 0.05

STO fault trips even if the load is not

too high

Induced Voltage Constant (E5-09

or E5-24)

• Check and adjust the induced voltage constant.

• Check the motor name plate, the data sheet or contact the motor

manufacturer for getting data.

dep. on drive

capacity and

motor code

Refer to the motor

data sheet o

r the

nameplate.

SIEP_C710616_35.book 258 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...